Integral connecting structure of transformer and current sensor

A current sensor and transformer technology, applied in the field of sensors, can solve the problems of increasing the signal-to-noise ratio of collected signals, increasing grounding inductance, interference, etc., and achieve the effects of reducing series input, reducing inductive reactance, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

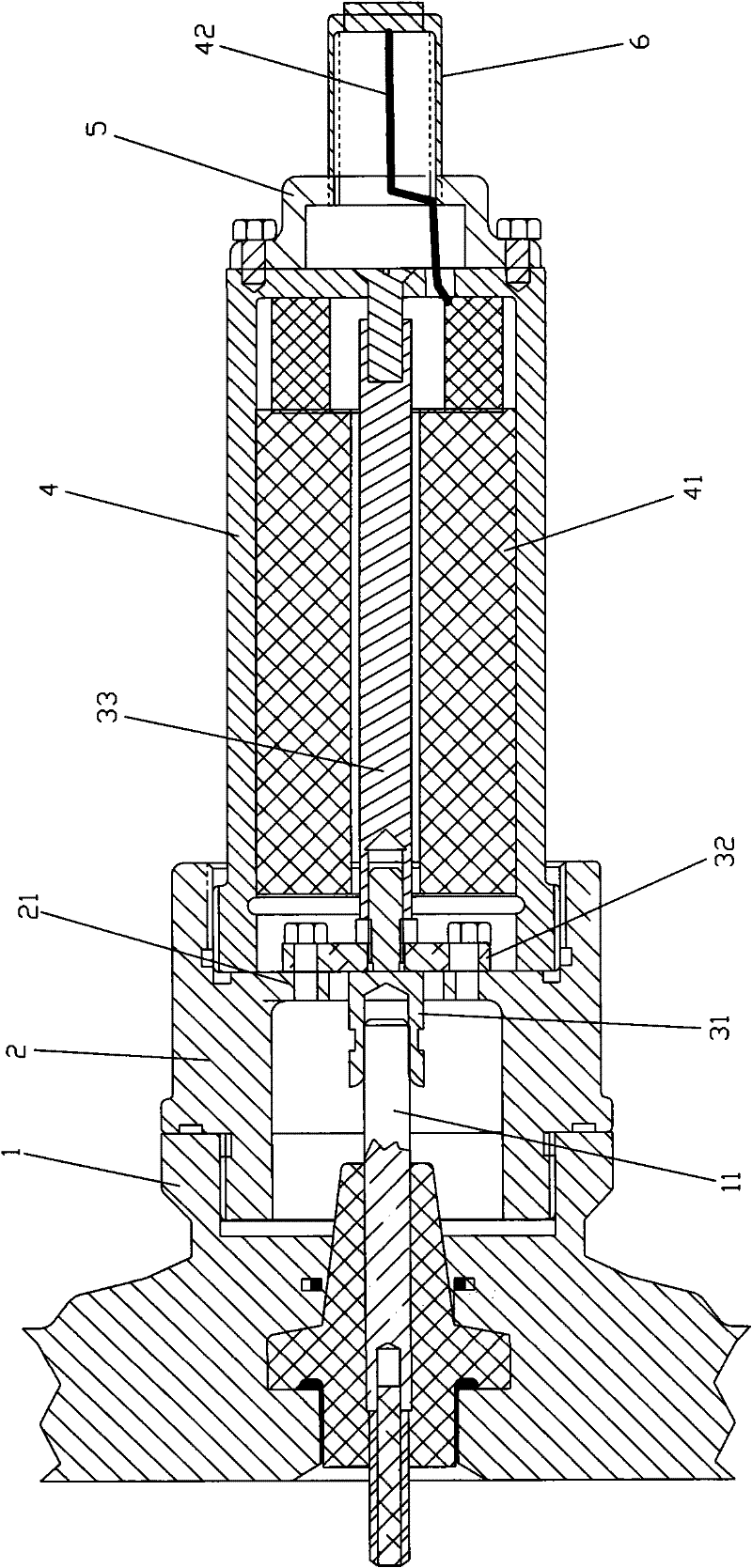

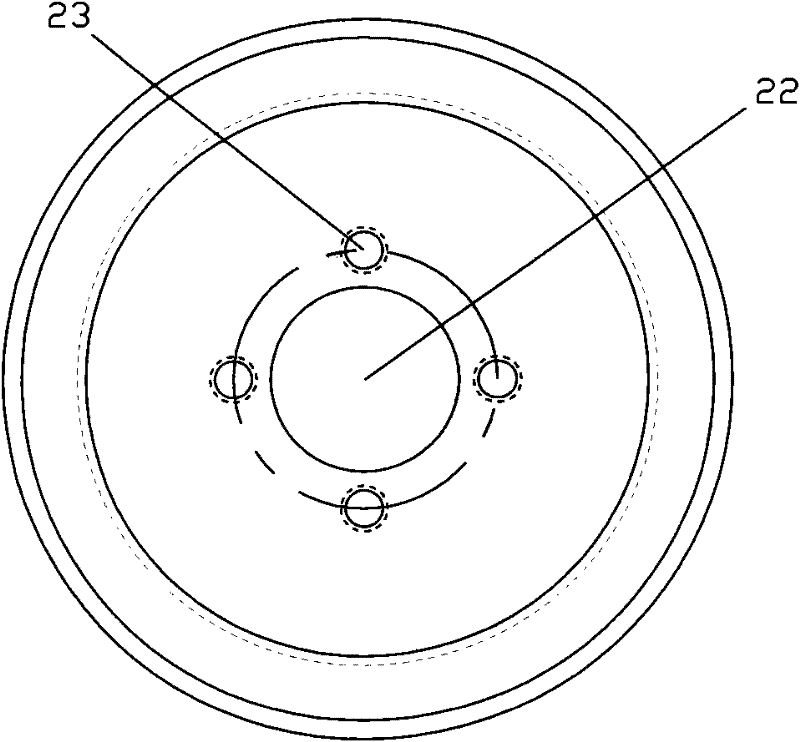

[0023] Such as Figure 1a and 1b As shown, the integrated connection structure of the transformer and the sensor of the present invention includes a sensor cover 4, a sensor core 41 is arranged in the sensor cover 4, and the sensor cover 4 is connected as a whole with the transformer end screen bushing 1 through the adapter 2, wherein the adapter 2 is a barrel-shaped structure, the front end of which has a thread to match the screw thread of the end screen sleeve 1, so that the adapter 2 is connected with the end screen sleeve 1, the rear end of the adapter 2 is connected with the front end of the sensor cover 4, and the upper edge of the adapter 2 The direction of the centerline of the adapter 2 is symmetrically provided with two mounting plates 21 perpendicular to the centerline of the adapter 2, such as Figure 2a and 2b As shown, there are through holes 22 between the mounting plates 21 of the adapter 2, and an elastic copper sleeve 31 connected to the ground terminal 11 ...

Embodiment 2

[0027] In the integrated connection structure of the transformer and the sensor of the present invention, the conductive rod therein can also be replaced by a grounding wire, so that the insulating electrical board 32 can be omitted, and the two ends of the grounding wire are respectively connected to the end screen grounding terminal 11 and the tail end of the sensor cover 4 Wrapped and fixed, other structures and connection methods are the same as in Example 1.

[0028] The loading and unloading process of the integrated connection structure of the transformer and the current sensor of the present invention is as follows:

[0029] Install

[0030] 1: Insert the elastic copper sleeve into the grounding terminal of the transformer end screen bushing.

[0031] 2: Screw the adapter with the O-ring onto the screw thread of the bushing at the end of the transformer, and tighten it.

[0032] 3: Install the insulating electrical board on the adapter with a stainless steel machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com