Lifting device of automobile chassis

A lifting device and vehicle chassis technology, applied in vehicle maintenance, transportation and packaging, lifting vehicle accessories, etc., can solve the problems of inconvenient maintenance, time-consuming and laborious, and the car cannot find a parking space, so as to facilitate maintenance or replacement of tires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

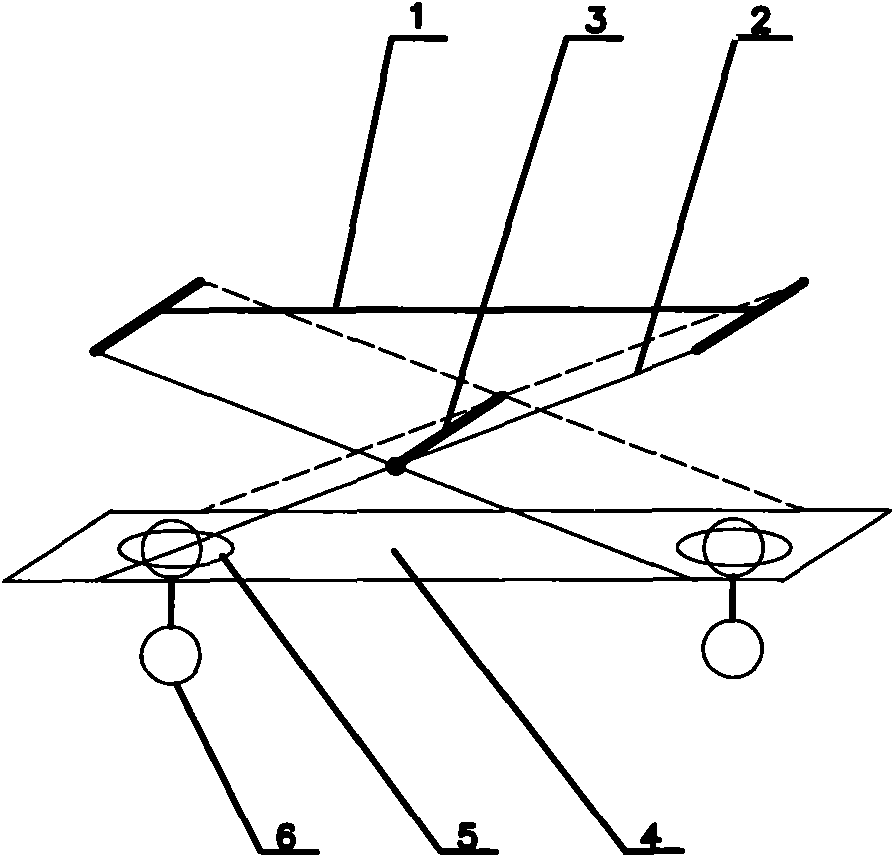

[0011] Such as figure 1 As shown, a car chassis lifting device includes an electric device 1, two lifting plates 2, a rotating shaft 3, a base plate 4, a universal wheel 5, and a driving wheel 6, and the two ends of the power device are installed on the lifting plate The upper part is installed on both ends of the bottom plate through the two intersecting lifting plates. The intersection of the two lifting plates is equipped with a rotating shaft. Universal wheels are installed on both sides of the bottom plate, and driving wheels are installed on the lower part of the universal wheel. The power unit described above is a hydraulic unit or an electric unit. The electric device is a driving device composed of a motor and a worm gear reducer, or a hydraulic driving device, and the universal wheel is used to adjust the angle of the driving wheel.

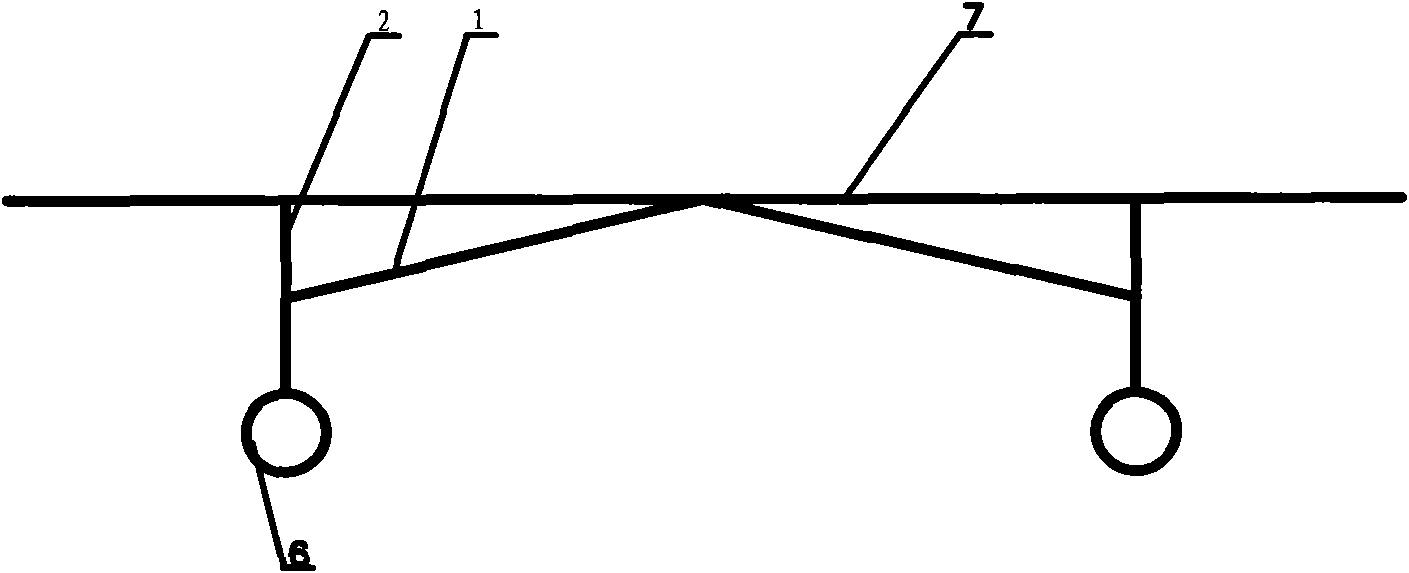

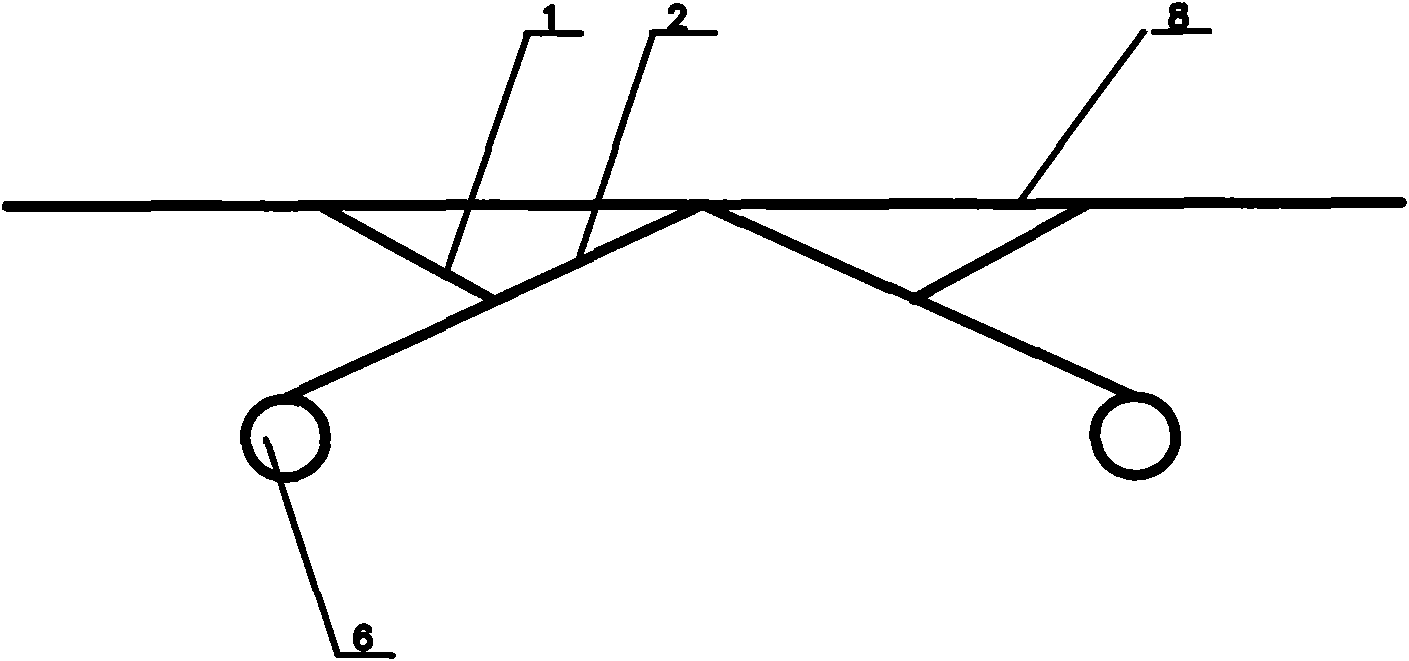

[0012] Such as figure 2 and image 3 Shown, above-mentioned a kind of automobile chassis lifting device is independently installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com