Easy to disassemble hydraulic buffer device

A hydraulic buffer and easy disassembly technology, applied in the direction of shock absorbers, springs, spring/shock absorbers, etc., can solve the problems of waste of resources, difficulty in ensuring sealing, high cost, etc., and achieve reduced use costs, convenient replacement, and tightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

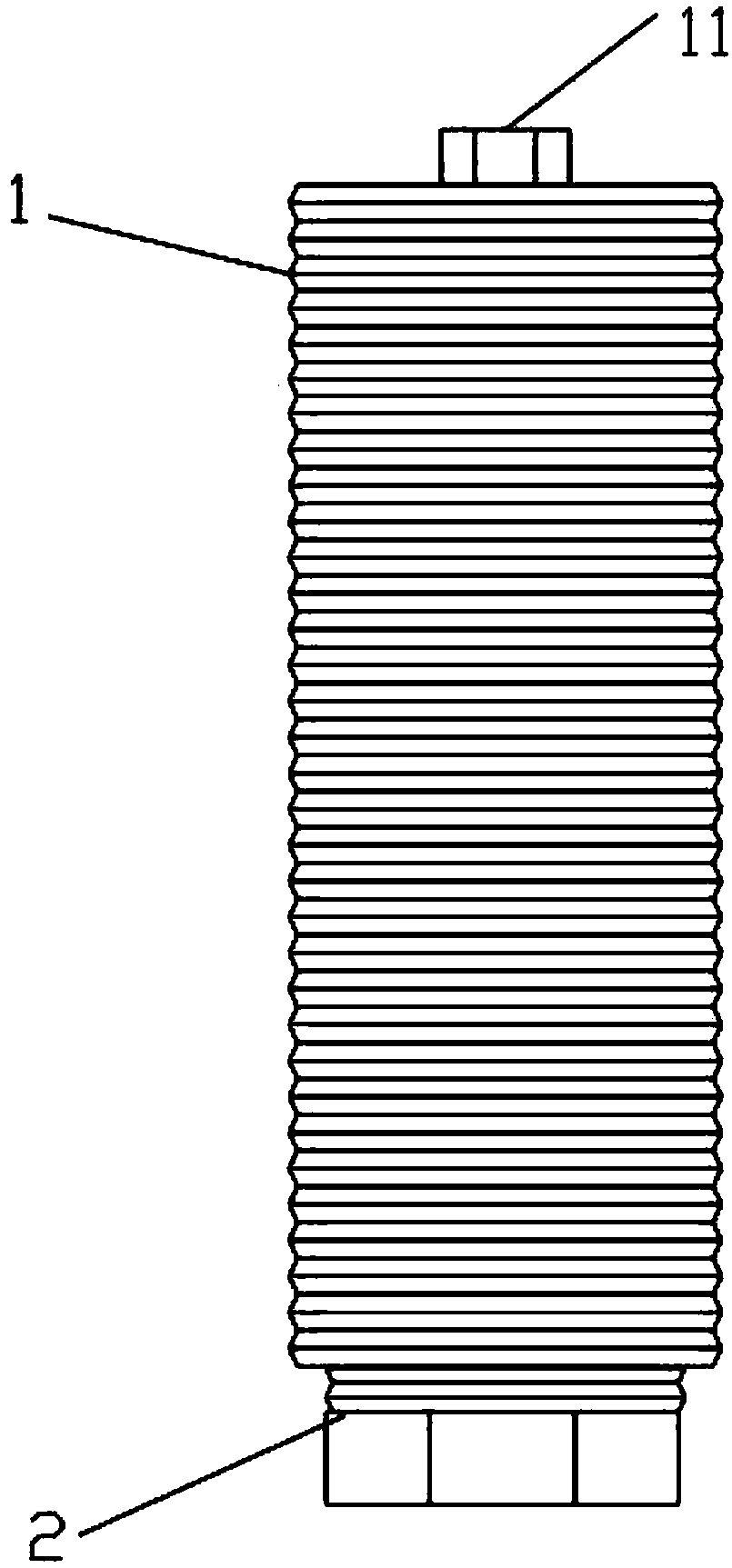

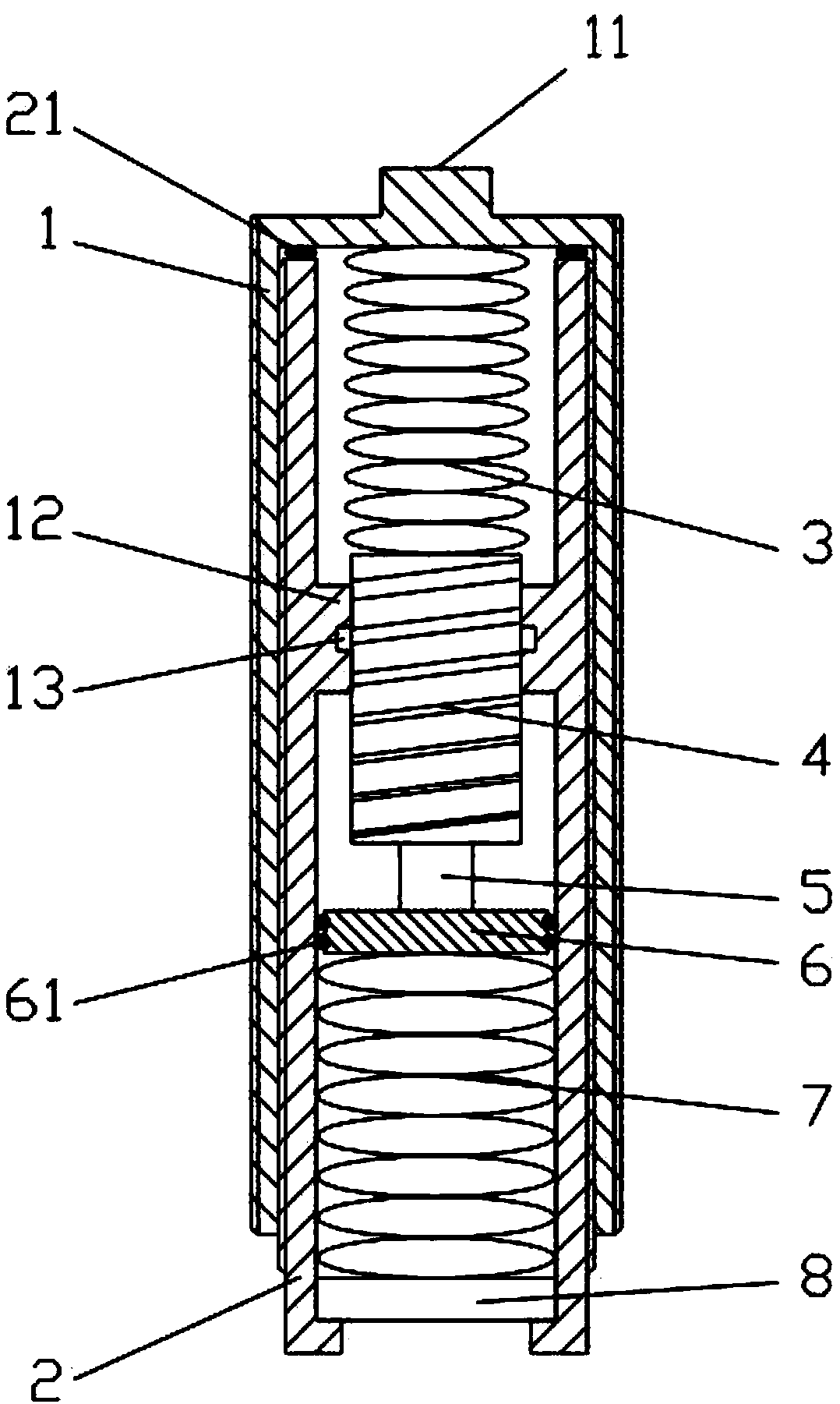

[0015] Such as figure 1 and figure 2 As shown, an easy-to-disassemble hydraulic buffer device includes a threaded main body 1 and a core body 2. Threaded main body 1 is provided with threads on the outside for fixing the present invention on a machine. As a buffer device for a machine, one end of the threaded main body 1 is closed end, the outside of the closed end is fixed with a hexagonal nut 11 for using a wrench to rotate the present invention into a corresponding place for fixing.

[0016] Such as figure 2 As shown, the core body 2 is arranged inside the threaded body 1 and is threadedly connected with the threaded body 1. The outer shape of the lower end of the core body 2 is hexagonal, which is used to screw the core body 2 into the threaded body 1. The upper end of the core body 2 It abuts against the closed end of the threaded main body 1, and a sealing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com