New downlight structure

A downlight, a new type of technology, applied in the field of lighting, can solve problems such as unfavorable standardized production efficiency, incompatibility and mutual assembly of products, and lack of unified industry standards, so as to improve production efficiency and market effect, and achieve large-scale production and popularization. The effect of convenient application and appearance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

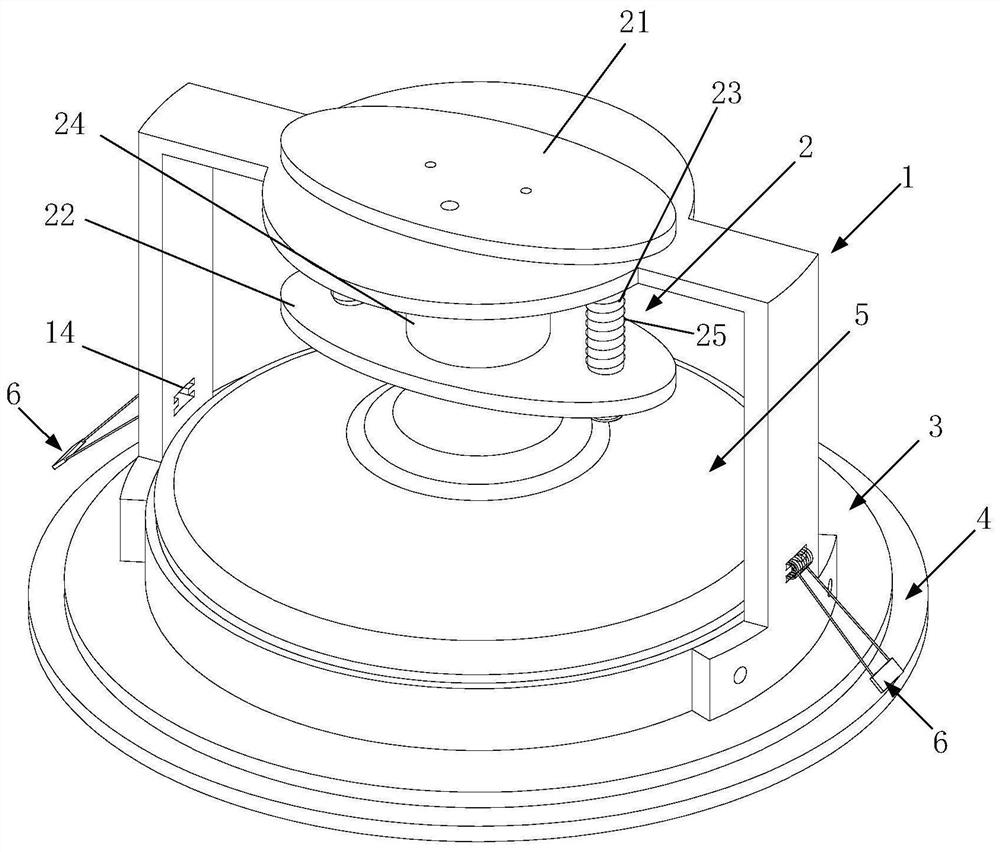

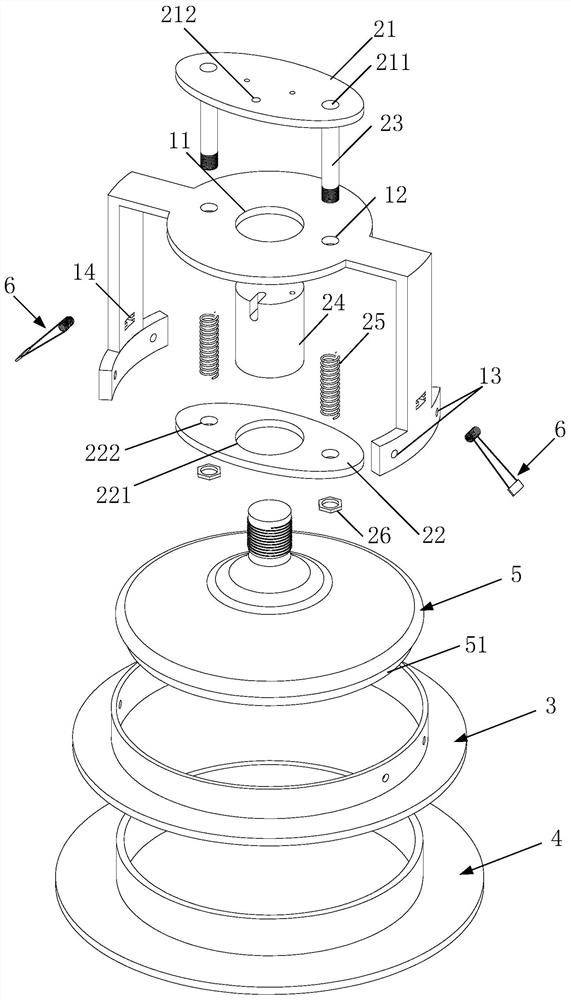

[0053] see figure 1 , figure 2 As shown, a new downlight structure includes a vertical lamp body and a light source 5. The vertical lamp body includes a vertical bracket 1, a movable lamp holder assembly 2, a base 3 and a support ring 4, and the movable lamp holder assembly 2. It is movably connected to the top of the vertical support 1. The base 3 is fixed on the bottom of the vertical support 1 with screws. The support ring 4 is closely combined with the inner wall of the base 3 through a connecting piece; the light source 5 and the movable lamp holder assembly 2 connection, the bottom surface of the light source 5 is provided with a light source boss 51, when the light source 5 is connected to the movable lamp holder assembly 2, the light source boss 51 is just inserted into the inner hole of the support ring 4, limiting the light source 5 in the support ring 4 Horizontal displacement on the ring 4, the light source 5 is supported by the support ring 4 in a static state, ...

Embodiment 2

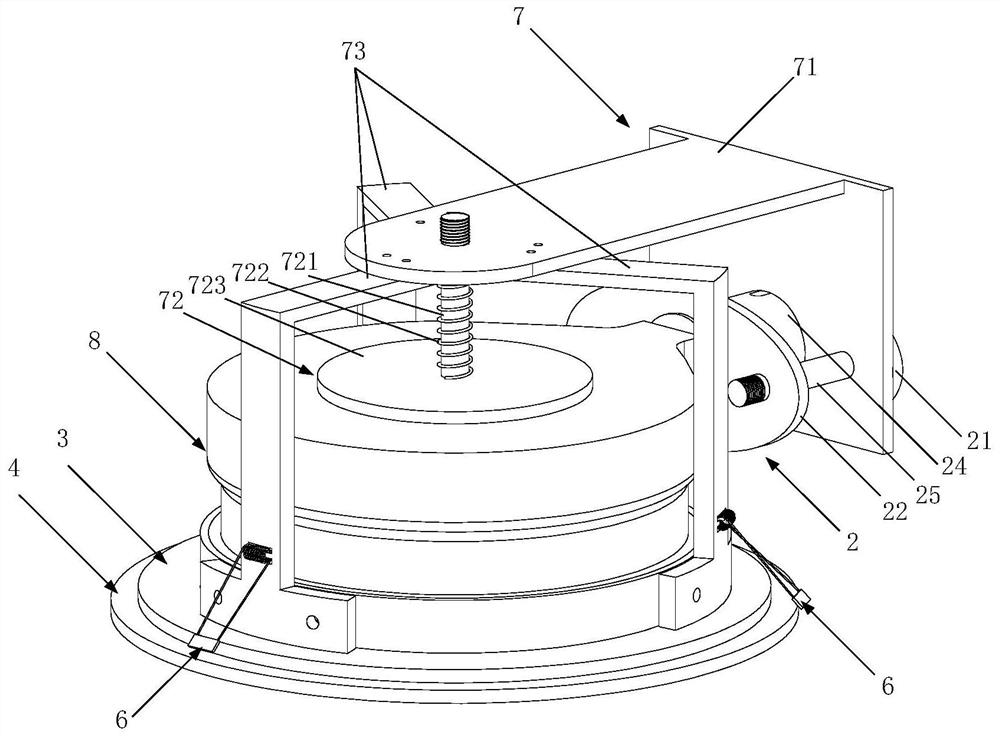

[0059] see image 3 , Figure 4 , Figure 5 As shown, a new downlight structure includes a horizontal lamp body and a horizontally inserted light source 8,

[0060] The horizontal lamp body includes a horizontal bracket assembly 7, a movable lamp base assembly 2, a base 3 and a support ring 4, the movable lamp base assembly 2 is movably connected to the side plate of the horizontal bracket assembly 7, and the base 3 passes through It is fixed on the bottom of the cantilever 73 of the horizontal bracket assembly 7 by riveting, and the support ring 4 is closely combined with the inner wall of the base 3 through a connecting piece; the horizontally inserted light source 8 is connected to the movable lamp holder assembly 2, and the horizontally inserted The light outlet part of the bottom surface of the light source 8 is provided with a horizontal insertion light source boss 81. When the horizontal insertion light source 8 is connected with the movable lamp holder assembly 2, th...

Embodiment 3

[0066] see Figure 6 , Figure 7 As shown, a new downlight structure includes a surface-mounted lamp body and a light source. The surface-mounted lamp body includes a cavity 91, a cavity top cover 92, a movable lamp holder assembly 2 and a support ring 4. The movable The lamp holder assembly 2 is movably connected on the top cover 92 of the cavity, and the top cover 92 of the cavity is installed on the top of the cavity 91 with screws, the bottom of the cavity 91 has a central hole, and the support ring 4 is connected to the cavity The inner wall of the center hole at the bottom of the body 91 is tightly combined through a connecting piece; the light source 5 is connected to the movable lamp holder assembly 2, and the light outlet part of the bottom surface of the light source 5 is provided with a boss 51. When the light source 5 is connected to the movable lamp holder assembly 2, The light source boss 51 is just placed into the inner hole of the support ring 4 to limit the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com