Structure for quickly eliminating putty at bottom of weighing material tank

A material tank, fast technology, applied in the direction of inspection device, bell and funnel arrangement, etc., can solve the problems of gas poisoning, burns, time-consuming, etc., and achieve the effect of avoiding gas poisoning, increasing iron output, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

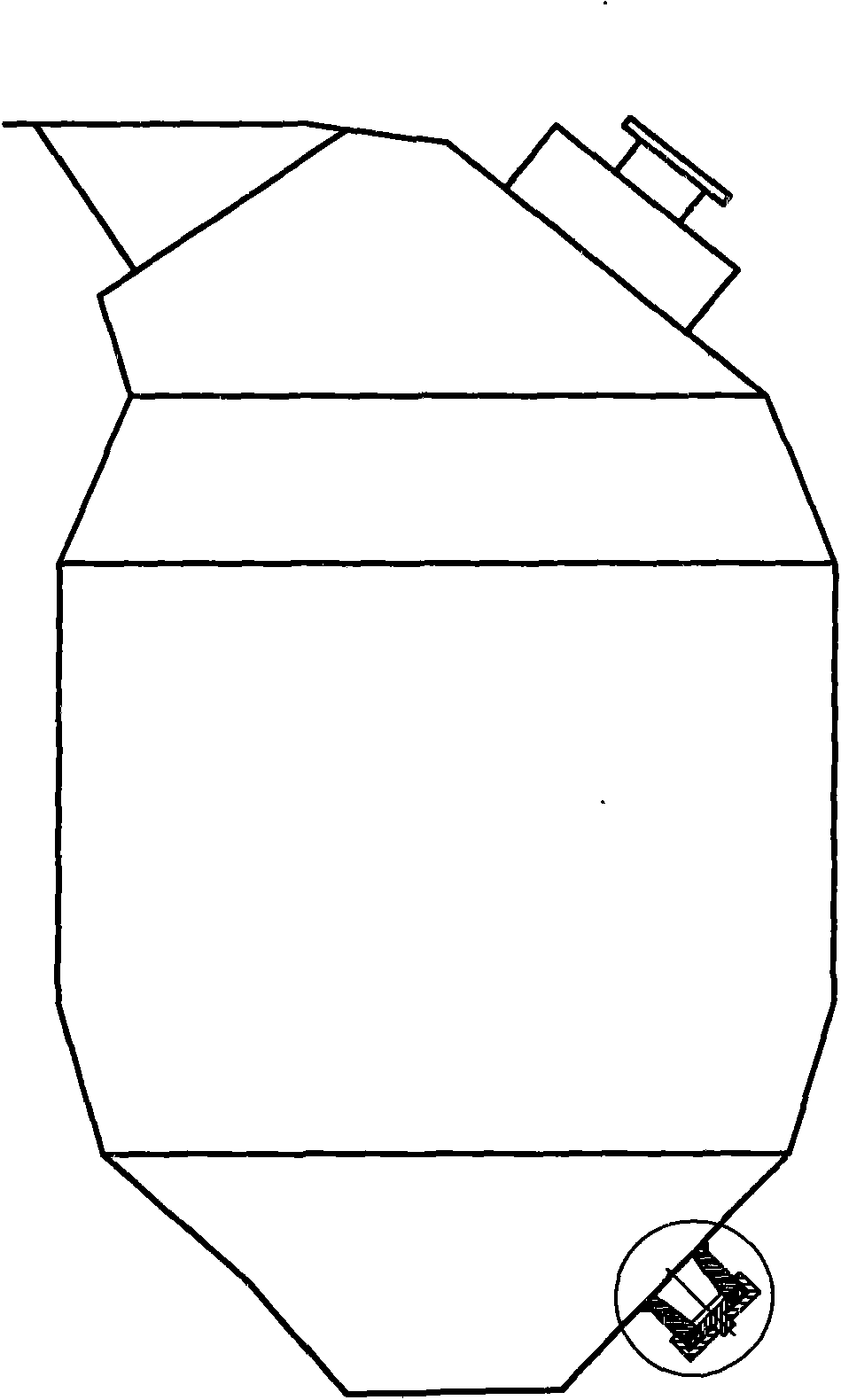

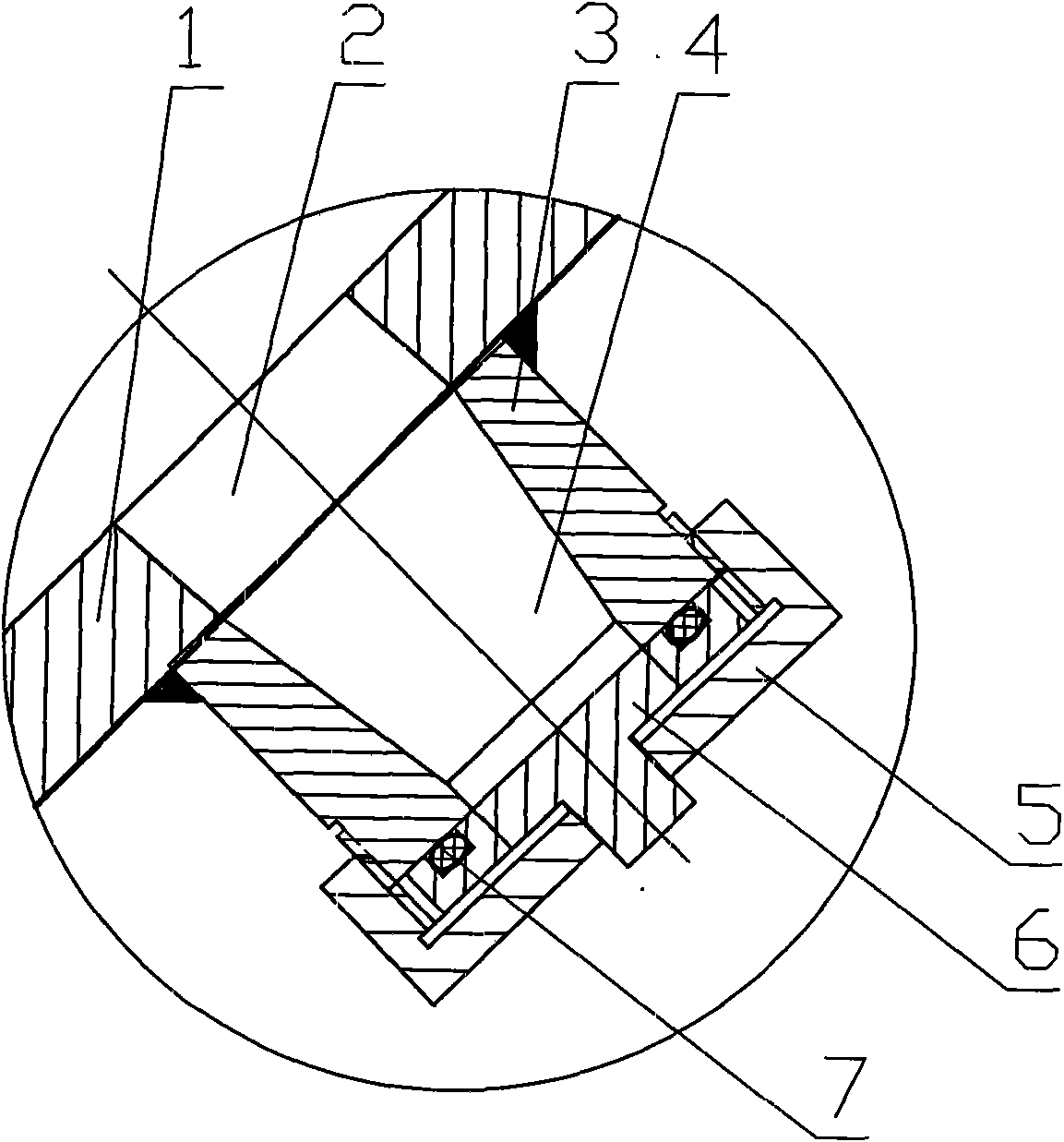

[0019] When the material jam occurs, open the lower sealing valve and find that the material jam is above the airtight box of the weighing material tank. The material in it will fall, so it is decided to open a hole at the bottom of the weighing tank above the airtight box. In order to avoid damage to the internal guard plate of the weighing tank after opening the hole, thereby affecting its strength and reducing the life of the guard plate, the present invention decides to open the hole from the middle of the two guard plates in the weighing tank.

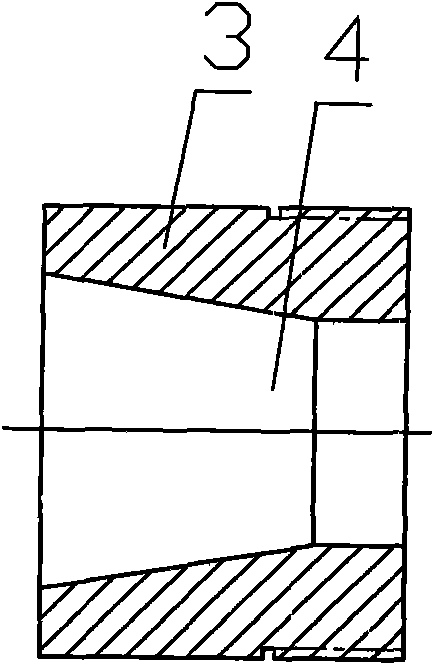

[0020] In order to ensure that the pressure of the weighing tank is not affected after the material hole is opened (to ensure that the tank does not leak). Therefore, it is necessary to design a sealing combination with good sealing performance. If a sealing combination of one seat and one cover is used, the sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com