Carbon composite blast furnace iron runner castable

A iron channel castable and carbon composite technology, which is applied in the field of refractory materials, can solve the problems of short service life of iron channel castables, cracks in refractory castables, and low iron production, so as to increase iron production and prolong service life , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

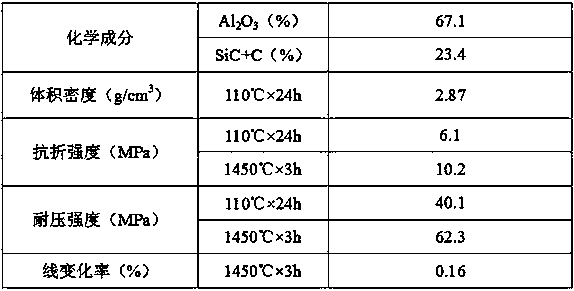

Embodiment 1

[0035] Embodiment 1 prepares 2000m 3 Blast furnace iron ditch castable

[0036] Its raw material ratio is:

[0037] 52 parts of fused brown corundum with particle size 1~8mm;

[0038] 8 parts of fused dense corundum with particle size 0~1mm, 5 parts of 325 mesh fused dense corundum;

[0039] 10 parts of silicon carbide with particle size 0~1mm; 9 parts of 200 mesh silicon carbide;

[0040] 2 parts of pure calcium aluminate cement fine powder;

[0041] 2.5 parts of silicon micropowder with a particle size of 1 μm;

[0042] 7 parts of bimodal activated alumina micropowder with a particle size of 3-5 μm;

[0043] 2 parts of spherical asphalt with a particle size of 0.2~0.5mm;

[0044] 0.5 part of carbon black powder, 0.3 part of carbon resin powder;

[0045] 1.5 parts of metal silicon powder, 0.5 parts of boron carbide;

[0046] 0.05 parts of organic fibers with a melting temperature of 80~90°C can be used as Liaoyang Jintai JT-80 products;

[0047] Metal aluminum powder...

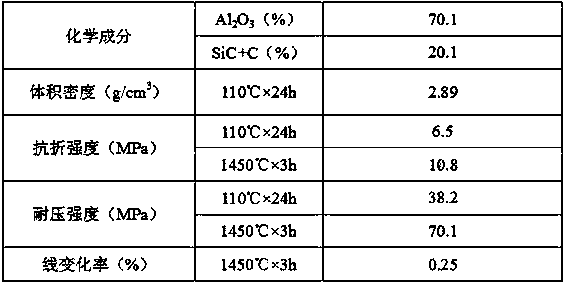

Embodiment 2

[0052] Embodiment 2 prepares 2500m 3 Blast furnace iron ditch castable

[0053] Its raw material ratio is:

[0054] 55 parts of fused brown corundum with particle size 1~8mm;

[0055] 5 parts of fused dense corundum with particle size 0~1mm, 3 parts of 325 mesh fused dense corundum;

[0056] 11 parts of silicon carbide with particle size 0~1mm; 11 parts of 200 mesh silicon carbide;

[0057] 1.5 parts of pure calcium aluminate cement fine powder;

[0058] 2 parts of silica powder with a particle size of 1 μm;

[0059] 6 parts of bimodal activated alumina micropowder with a particle size of 3-5 μm; 3

[0060] 3 parts of spherical asphalt with a particle size of 0.2~0.5mm;

[0061] 0.3 parts of carbon black powder, 0.3 parts of carbon resin powder;

[0062] Antioxidant metal silicon powder 2 parts, boron carbide 0.3 part;

[0063] 0.05 parts of organic fibers with a melting temperature of 80-90°C;

[0064] Metal aluminum powder explosion-proof agent 0.12 parts;

[0065]...

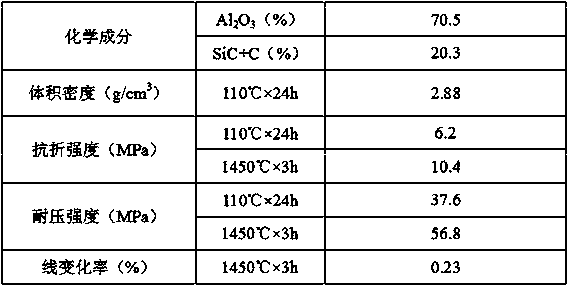

Embodiment 3

[0069] Embodiment 3 preparation 3000m 3 Blast furnace iron ditch castable

[0070] Its raw material ratio is:

[0071] 54 parts of fused brown corundum with particle size 1~8mm;

[0072]7 parts of fused dense corundum with particle size 0~1mm, 3 parts of 325 mesh fused dense corundum;

[0073] 12 parts of silicon carbide with particle size 0~1mm; 8 parts of 200 mesh silicon carbide;

[0074] 1.5 parts of pure calcium aluminate cement fine powder;

[0075] 2.5 parts of silicon micropowder with a particle size of 1 μm;

[0076] 7 parts of bimodal activated alumina micropowder with a particle size of 3-5 μm;

[0077] 2 parts of spherical asphalt with a particle size of 0.2~0.5mm;

[0078] 0.5 part of carbon black powder, 0.5 part of carbon resin powder;

[0079] 1.5 parts of antioxidant metal silicon powder, 0.5 parts of boron carbide;

[0080] 0.08 parts of organic fibers with a melting temperature of 80-90°C;

[0081] Metal aluminum powder explosion-proof agent 0.1 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com