High-thermal-conductivity molten iron trough castable

A technology for molten iron ditch and castable, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problem of not meeting the heat conduction requirements of the molten iron ditch, and achieves the improvement of the casting yard environment, thermal conductivity, and good oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of working lining castable for iron storage type molten iron ditch

[0043] Its raw material ratio is:

[0044] 45 parts of fused brown corundum with a particle size of 1~8mm;

[0045] 10 parts of fused dense corundum, including 7 parts of granular material with particle size of 0~1mm, and 3 parts of 325 mesh powder;

[0046] 8 parts of super bauxite with particle size of 3-8mm;

[0047] 30 parts of silicon carbide, including 18 parts of granular material with a particle size of 0~1mm, and 12 parts of 200 mesh powder;

[0048] 2 parts of pure calcium aluminate cement;

[0049] 3 copies of silicon micropowder with a particle size of 1 μm;

[0050] 8 parts of bimodal activated alumina micropowder with particle size of 3~5μm;

[0051] 4 parts of spherical pitch with a particle size of 0.2~0.5mm;

[0052] 1 part of nano carbon black powder;

[0053] 1 part of carbon resin powder;

[0054] 0.8 part of carbon dispersant;

[0055] 3 parts antioxi...

Embodiment 2

[0063] Example 2 Use effect comparison

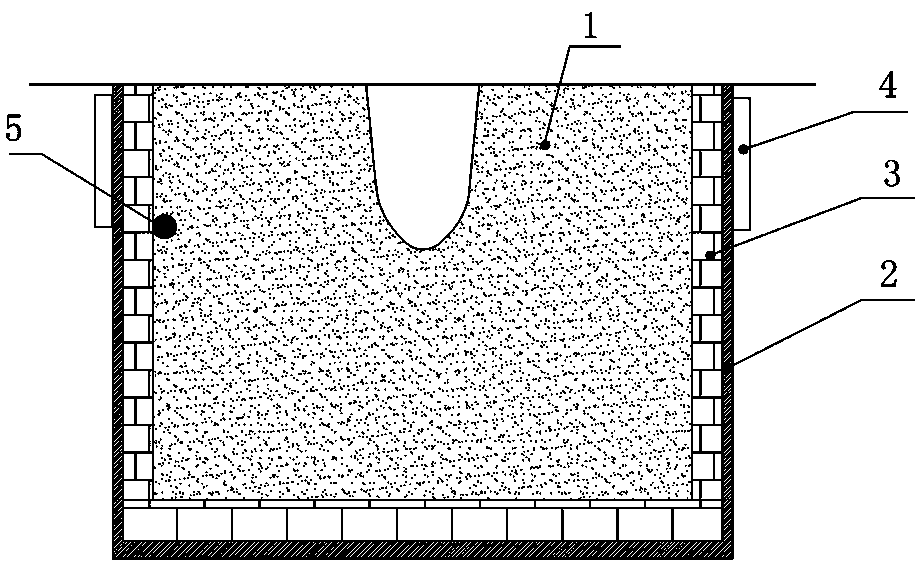

[0064] figure 1 It is a newly built iron storage type hot metal ditch with a total width of 2900mm, and a large and medium-sized iron-making blast furnace (volume 1080m 3and above) are used together. Its working layer 1 adopts the castable prepared in Example 1, with a thickness of 900 mm; a carbon-containing refractory brick layer 3 (thermal conductivity 15w / (m·k)) is built between the steel shell 2 and the working layer 1, and the outer steel shell 2 A water-cooling plate 4 is installed, and temperature measuring thermocouples 5 are arranged in the working layer 1 adjacent to the carbon-containing refractory brick layer 3 .

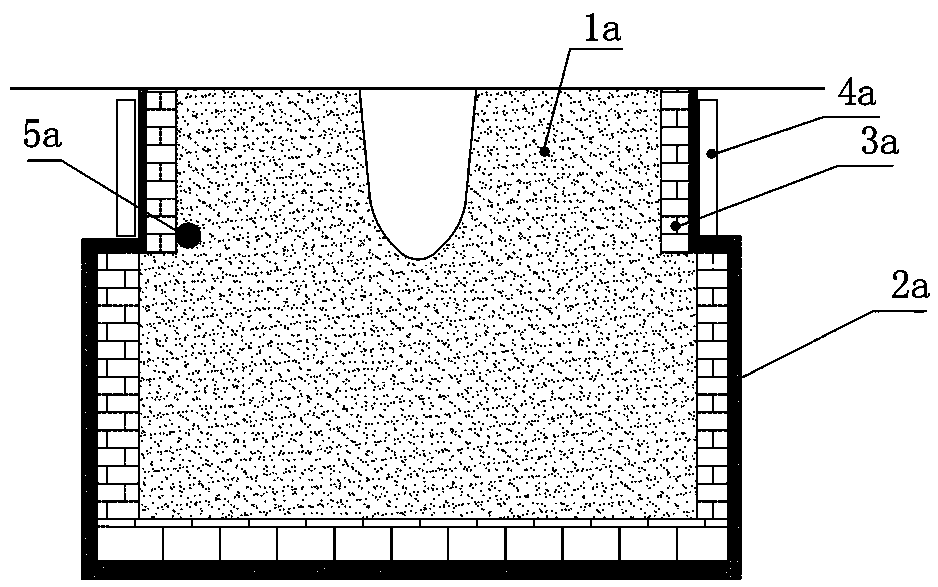

[0065] figure 2 It is an iron storage type iron ditch transformed from an ordinary iron ditch, and the total width is the same as figure 1 In the same way, in order to save resources and reduce renovation costs, only the original refractories (Al 2 O 3 - SiC-C as the main component of the castable) excavat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com