Method for restraining generation of manganous dithionate in process of leaching sulfur dioxide gas out of pyrolusite

A technology of manganese dithionate and sulfur dioxide, which is applied in the field of environmental protection and metallurgy, can solve the problems of increasing the difficulty of iron removal, intermittent feeding, and difficulty in meeting, and achieves the effect of inhibiting the formation of manganese dithionate

Inactive Publication Date: 2010-12-01

成都合众新能源科技有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if this method is used for industrial production, the following problems will occur: 1) the leaching temperature must reach above 95°C, and a large amount of heat energy needs to be consumed for heating the pulp; 2) the pH value of the leachate is lower than 3.5, and additional sulfuric acid needs to be consumed; 3 ) Although the oxidation-reduction potential (ORP) is greater than or equal to 550mV (relative to the Ag / AgCl reference electrode) by adjusting the concentration of Fe3+ / Fe2+; but the initial Fe3+ concentration is greater than 4g / L, not only need to add additional Fe3+, but also increase the subsequent Difficulty in removing iron (total iron is required to be less than 0.1mg / L for purification and iron removal); 4) The time for feeding SO2 during the leaching process is not less than 10h, which means that SO2 gas is fed intermittently, which is difficult to meet the needs of industrial continuous production

Due to the constraints of the above problems, this method has not been able to realize industrialization so far.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to view more

Abstract

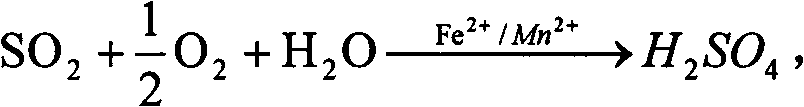

The invention discloses a method for restraining the generation of manganous dithionate in the process of leaching sulfur dioxide gas out of pyrolusite, which comprises the following main technical measures: (1) pyrolusite pulp is prepared by stirring and mixing in the proportion that 100-500g of pyrolusite and 0.2-100g of granular active carbon are added into 1L of water; (2) in a synchronous reaction process of absorbing the sulfur dioxide gas by the pyrolusite pulp, desulphurizing and leaching manganese, the pH value of the pyrolusite pulp is controlled to be lower than 3.5 by blowing oxygen or air into the pyrolusite pulp. The method restraining the generation of the manganous dithionate does not need to extra consume sulphuric acid and guarantee an oxido-reduction potential by extra adjusting the concentration of Fe<3+> / Fe<2+>, is easy to meet the requirement of industrial process production and can guarantee the concentration of a manganese sulfate mother liquor.

Description

Method for inhibiting the formation of manganese dithionite during leaching pyrolusite with sulfur dioxide gas technical field The invention relates to a method for inhibiting the formation of manganese dithionite in the process of leaching pyrolusite with sulfur dioxide gas or waste gas containing sulfur dioxide, which is used for improving the purity of manganese sulfate mother liquor in the process of leaching pyrolusite with sulfur dioxide gas or waste gas containing sulfur dioxide. The invention belongs to the technical fields of metallurgy and environmental protection. Background technique In the process of hydrometallurgical processing of pyrolusite, manganese dioxide (quaternary manganese) which is insoluble in acidic solution must first be converted into acid-soluble manganese monoxide (divalent manganese) through reduction reaction. The currently commonly used reduction roasting method requires large investment, high energy consumption, and great environmental po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C22B3/04C22B47/00

Inventor 苏仕军丁桑岚

Owner 成都合众新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap