Electromagnetic relay

An electromagnetic relay, electromagnetic technology, applied in electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of the number of parts, many assembly processes, complex structure, etc., and achieve the effect of fewer assembly processes, simple structure, and low magnetic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

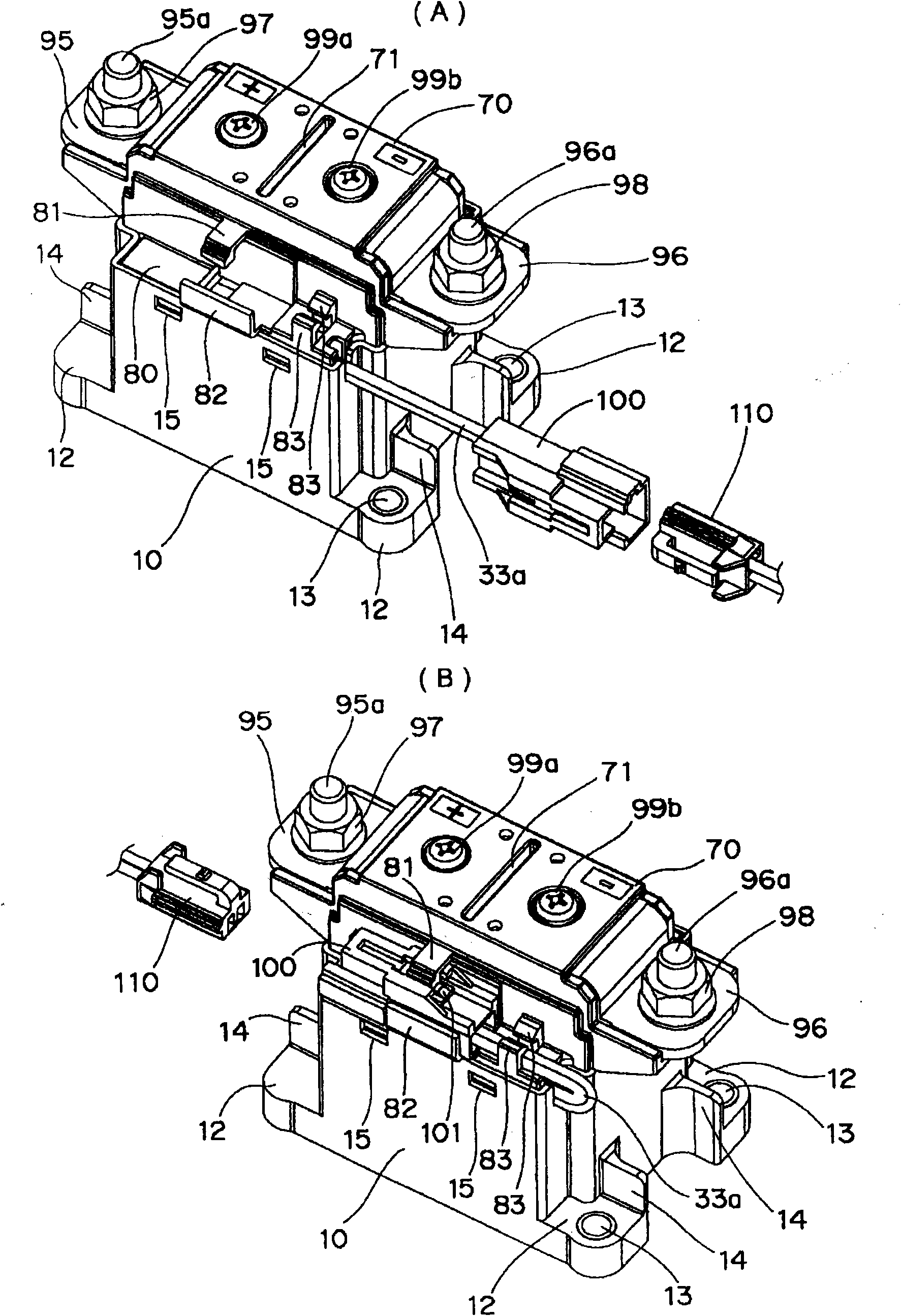

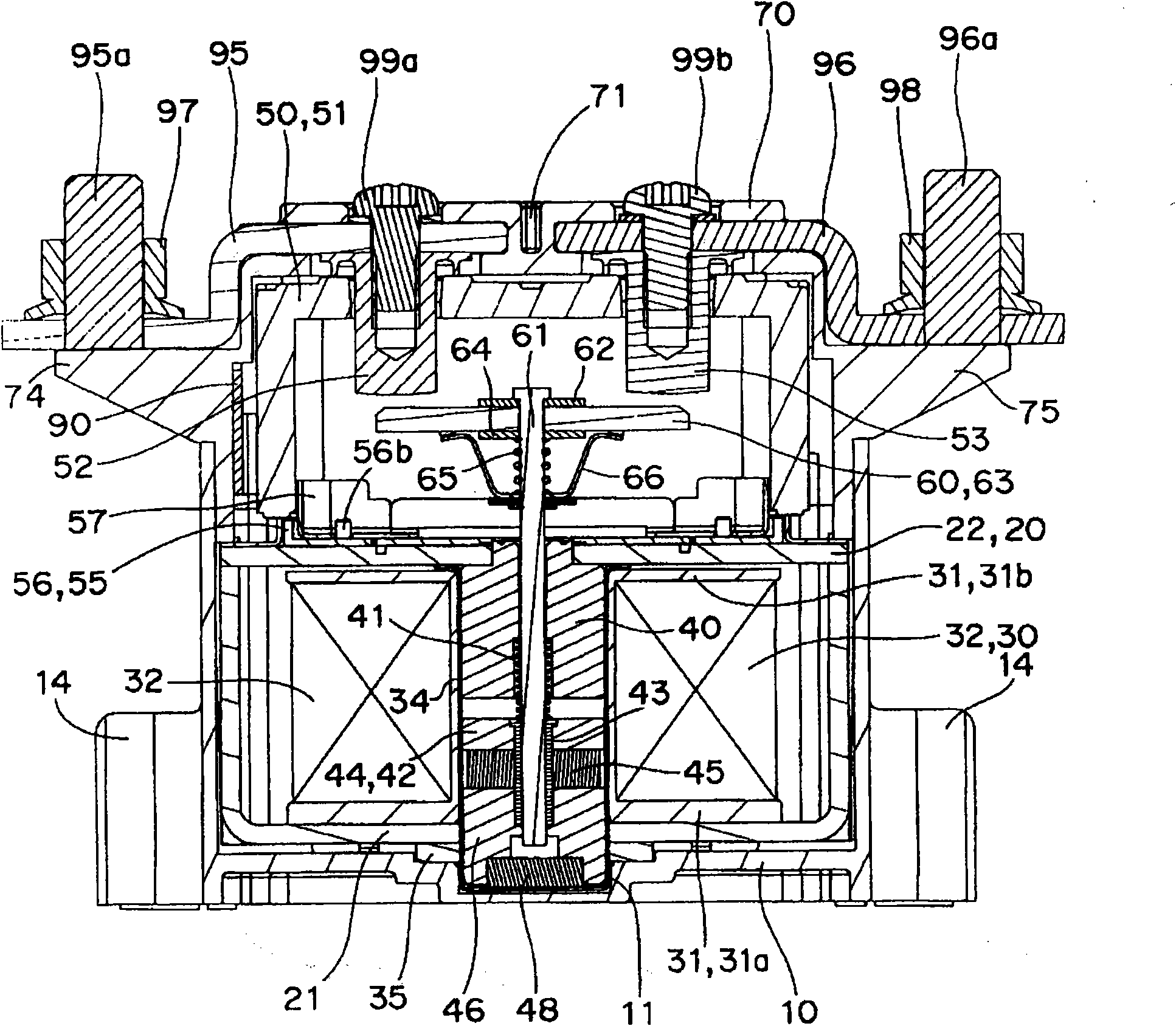

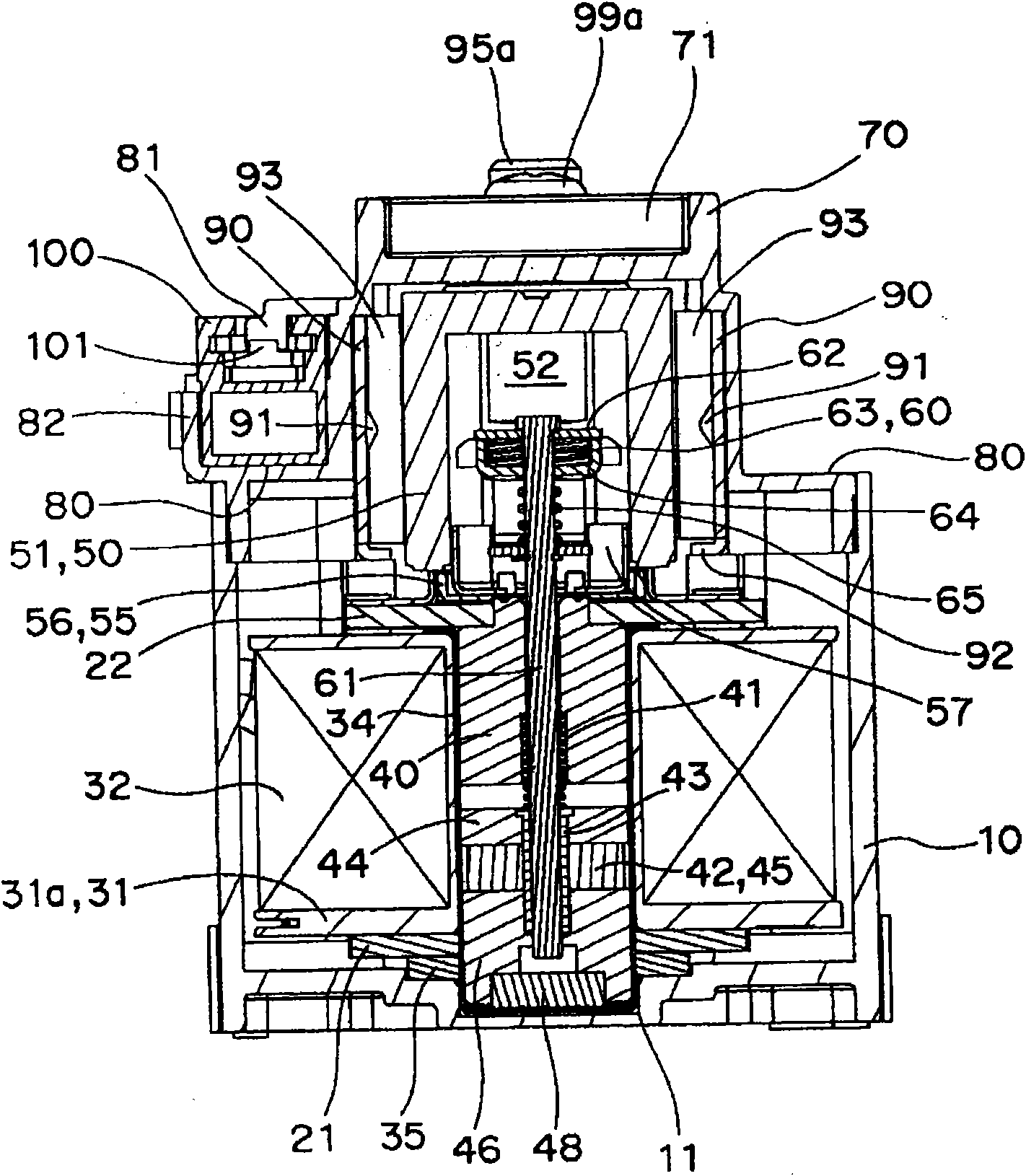

[0083] refer to Figure 1 to Figure 14 An electromagnetic relay for power loads, which is an embodiment of a contact device to which the present invention is applied, will be described.

[0084] like Figure 1 to Figure 13 As shown, the electromagnetic relay for power loads of the first embodiment has a general configuration: a drive mechanism assembly 20 and a contact mechanism assembly 50 integrated up and down are accommodated in a case (base) 10, and a cover 70 is fitted covered on the casing 10.

[0085] like Figure 4 As shown, the housing 10 is box-shaped with a bottom surface capable of accommodating the drive mechanism assembly 20 described later, and a fitting recess 11 for positioning the drive mechanism assembly 20 ( figure 2 and image 3 ). In addition, the casing 10 is provided with mounting holes 13 and reinforcing ribs 14 protruding from a base portion 12 protruding laterally from the lower edge portion of the outer peripheral corner portion. However, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com