Apparatus and method for reliability screening

A screening device and screening method technology, applied in sorting and other directions, can solve the problems that users cannot select and change the vibration frequency range, the vibration mode is complicated, and the operation is complicated, and achieves obvious reliability screening effect, easy to popularize and use, and operable. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

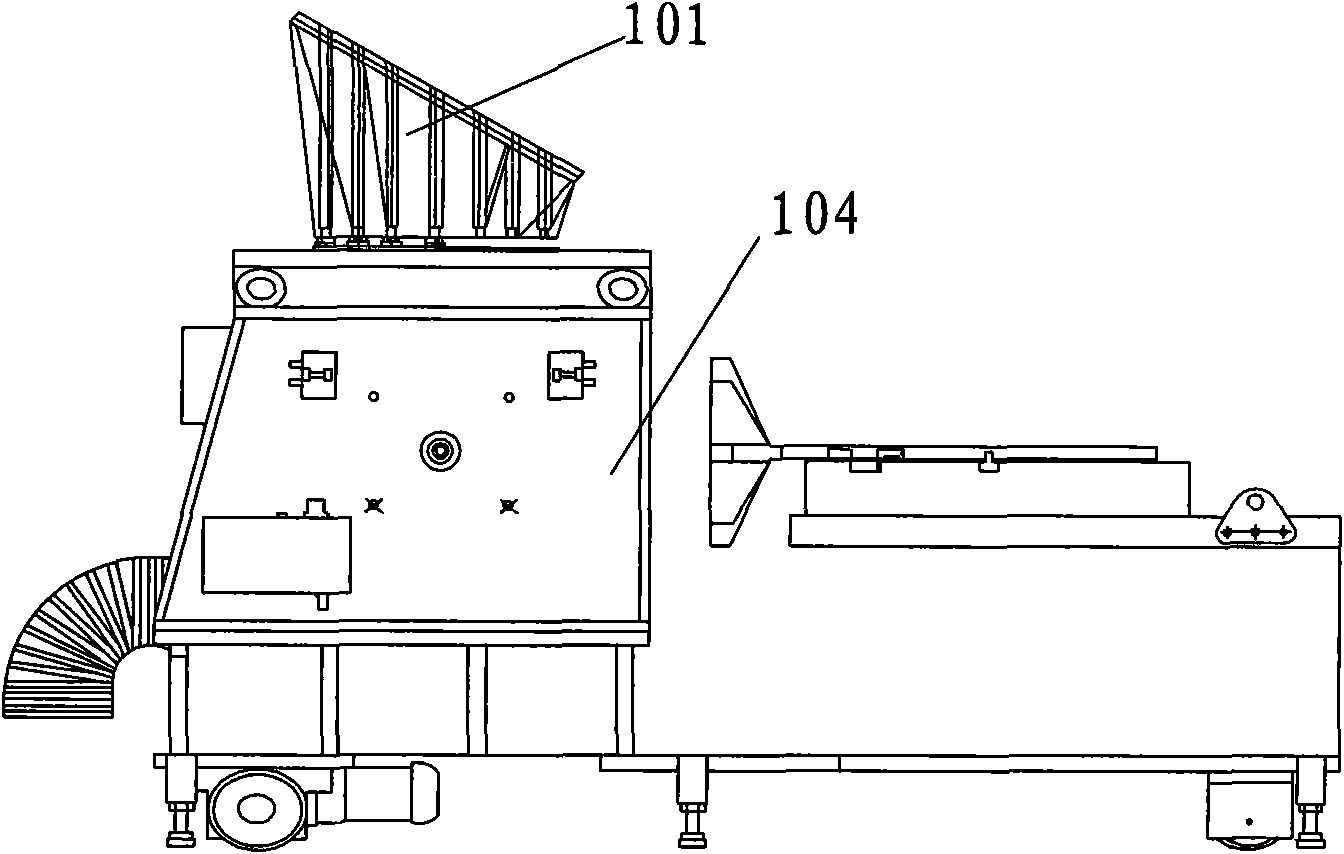

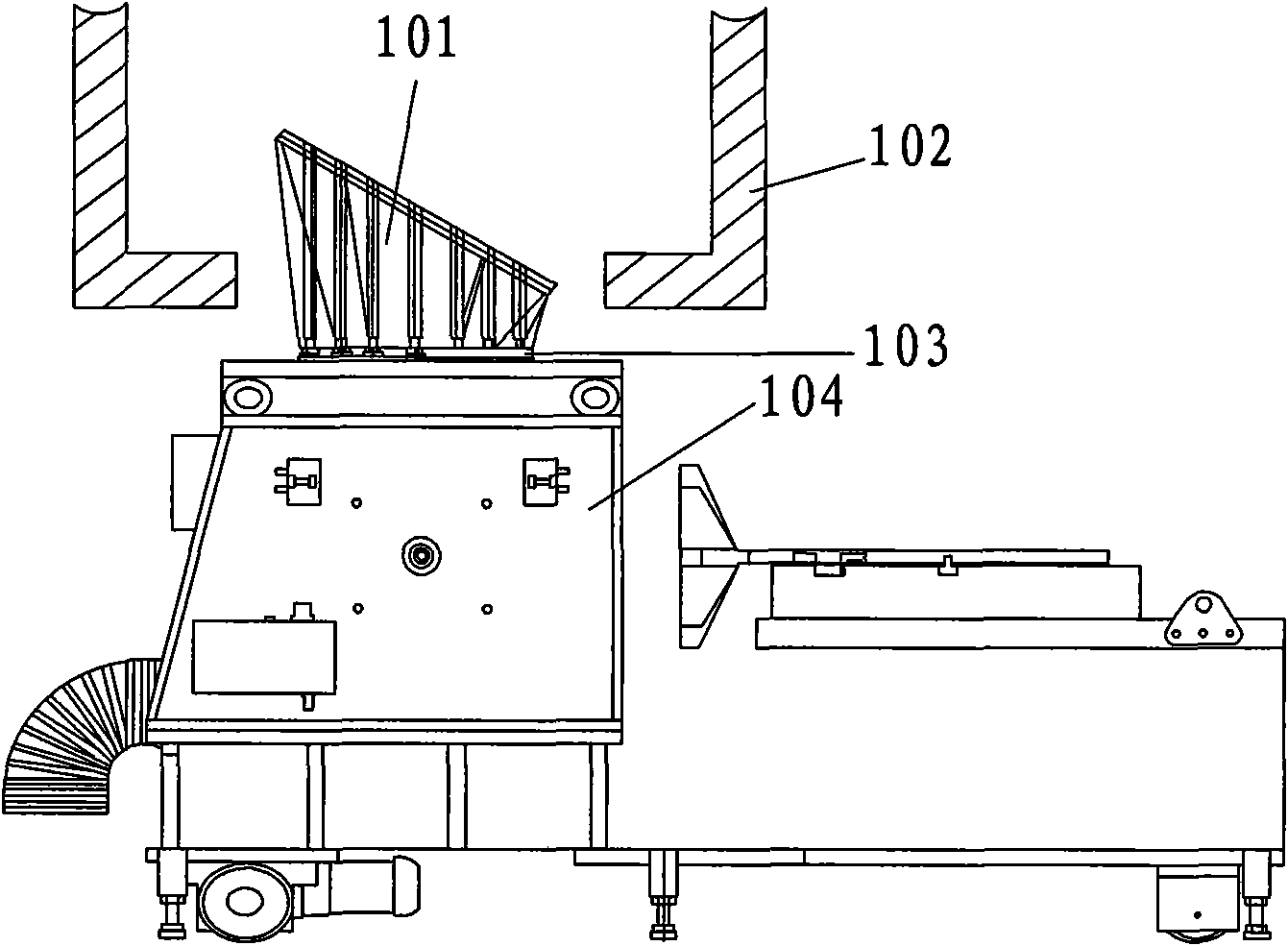

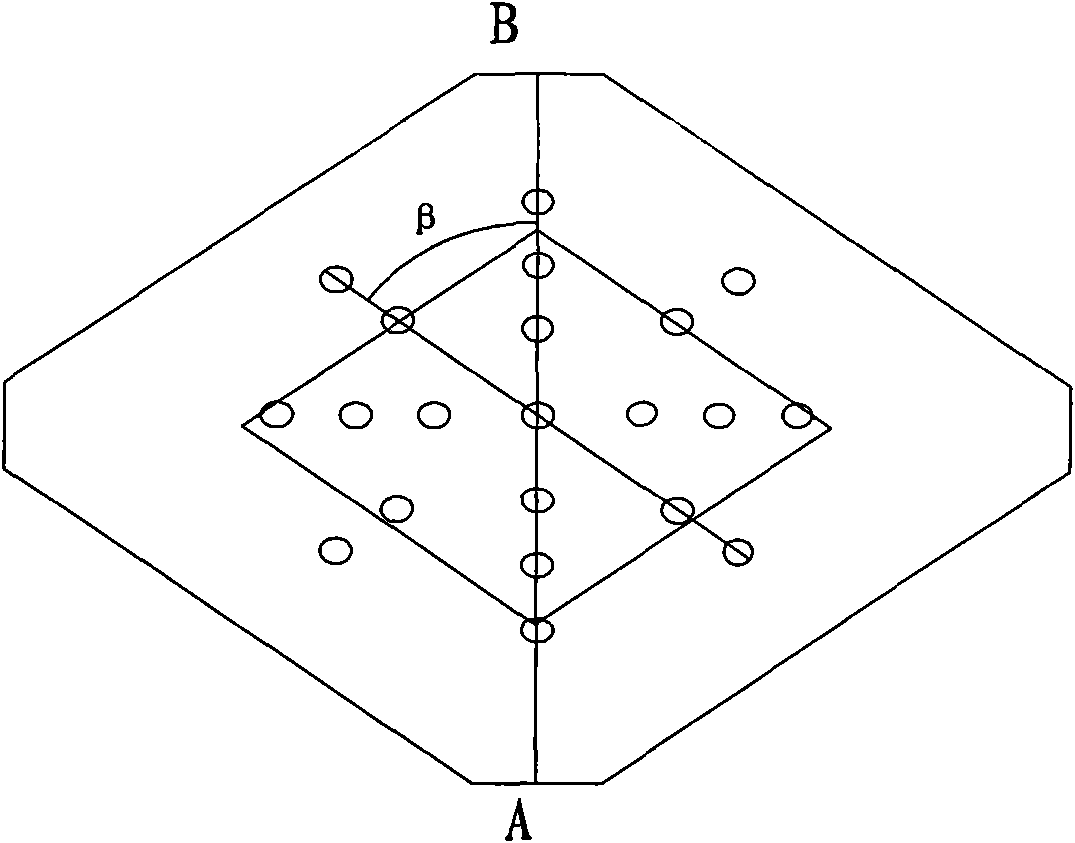

[0037] Such as Figure 1a Shown is a schematic structural view of the product reliability screening device described in the specific embodiment of the present invention, which can be used for three-dimensional vibration, two-dimensional vibration or one-dimensional vibration. The device includes an electromagnetic vibrating table 104 and an inclined plane fixture 101 , wherein the inclined plane fixture 101 is fixed on the electromagnetic vibrating table 104 . The meaning of the "incline" of the inclined-plane fixture 101 here is mainly to be inclined with respect to the vibration direction of the electromagnetic vibrating table 104. When the vibration direction is vertical, the inclined-plane of the inclined-plane fixture 101 is inclined to the horizontal plane. When the vibration direction is other directions, such as When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com