Stamping method for numerical control stamping machine tool

A punching machine tool and punching die technology, applied in the field of machinery, can solve problems such as size tolerance, part deformation, uncontrollable dimensional accuracy, etc., to achieve the effects of improving stability, avoiding easy deformation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

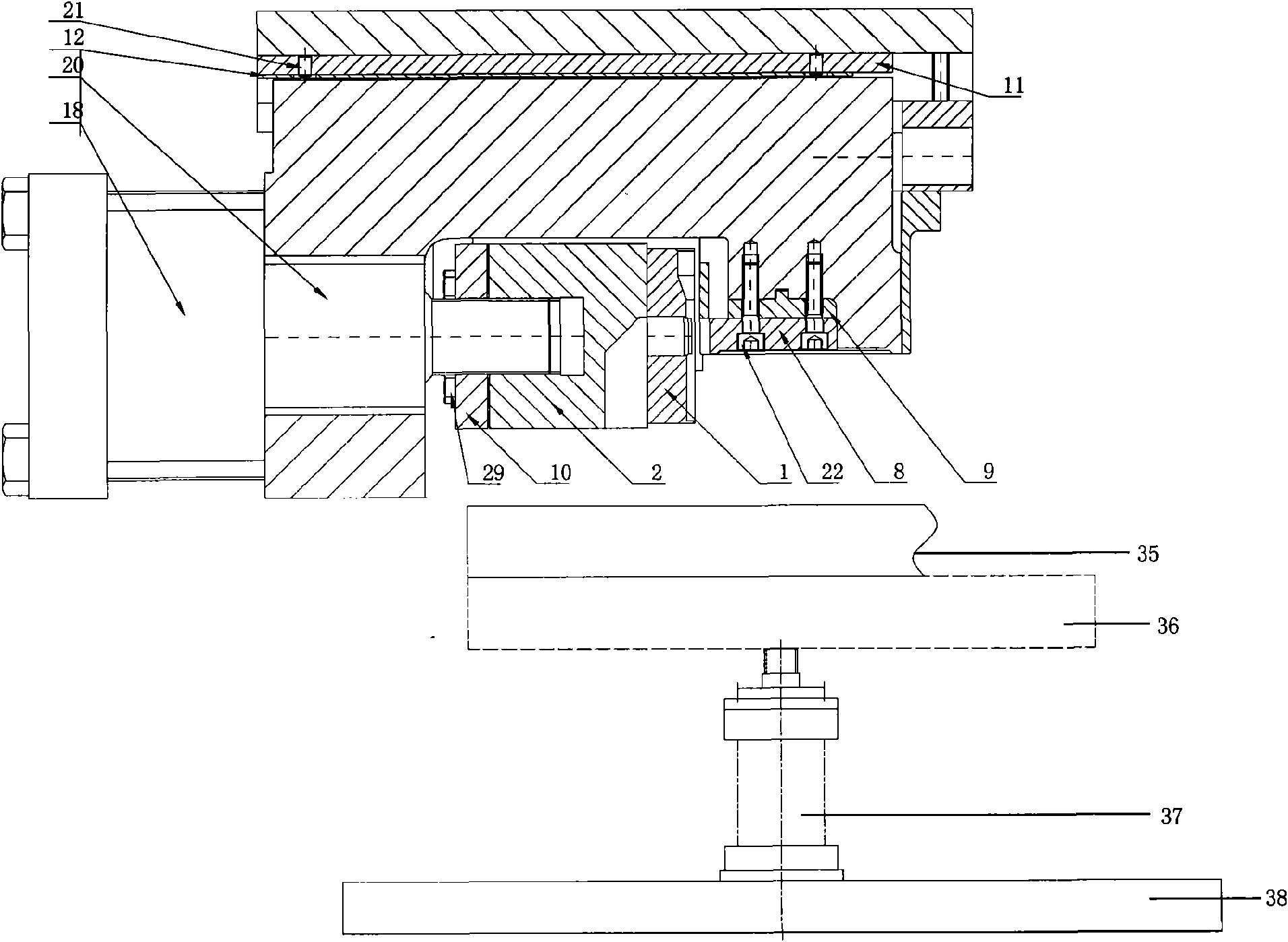

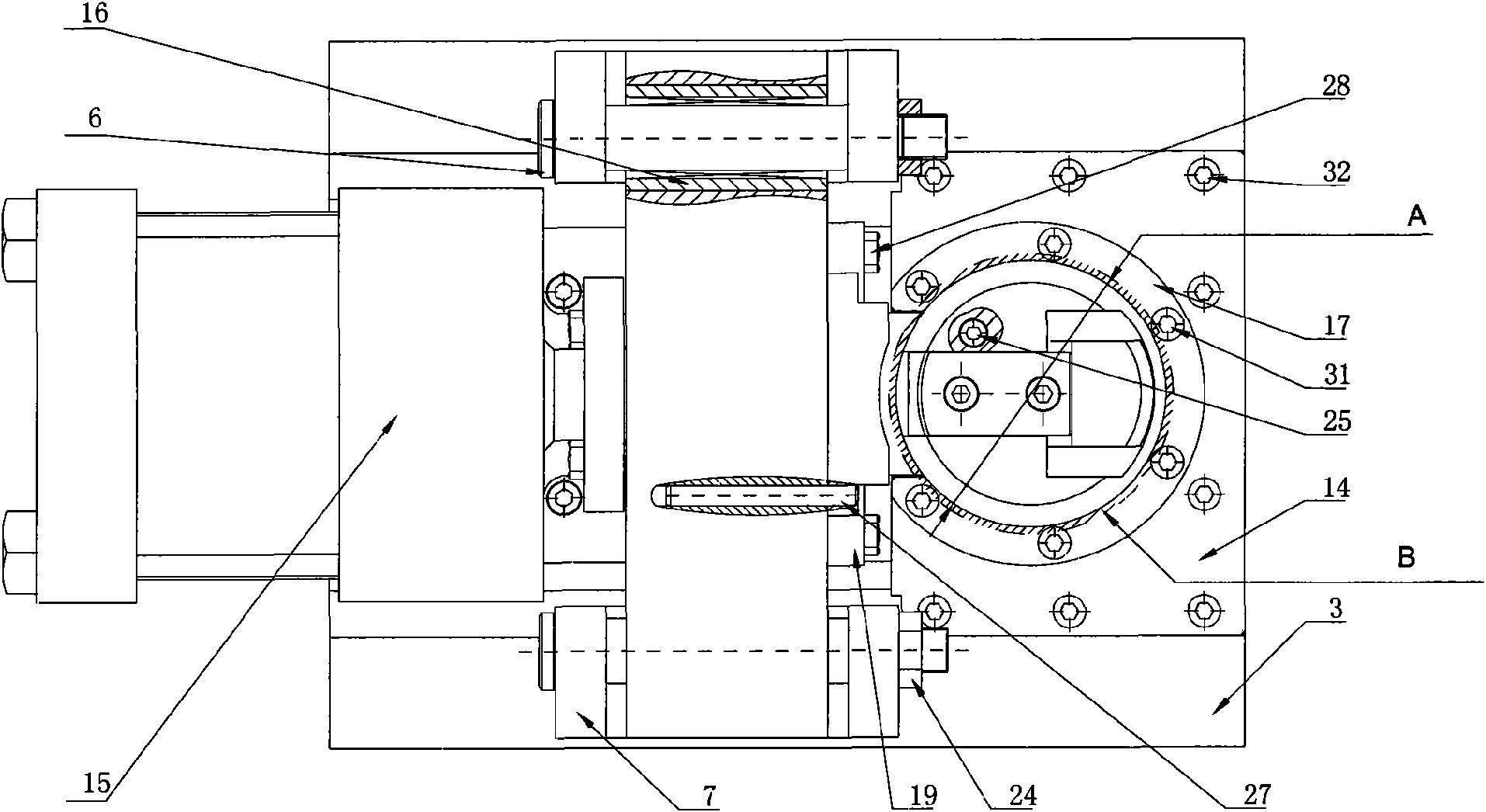

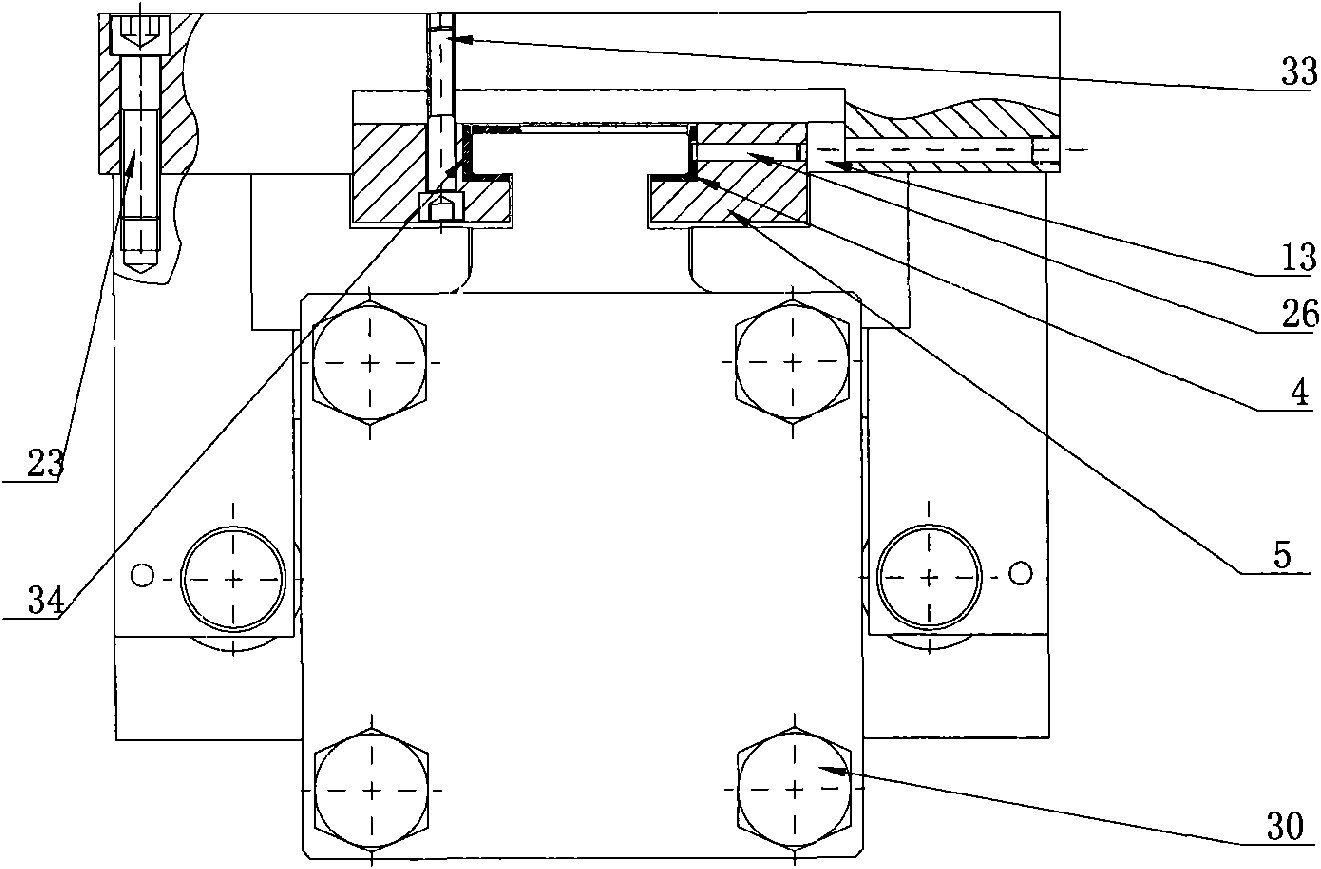

[0017] see figure 1 and combine figure 2 and image 3 , the die device shown in the figure includes a male die member and a female die member. The male mold member includes a lower mold 1 , a lower mold sliding seat 2 , a lower molding plate 19 , a cylindrical guide rail 6 , a cylindrical guide rail seat 7 , an inner corner thin nut 24 , a compression nut 10 , and a hexagon head bolt 28 . see figure 2 There are two cylindrical guide rail seats 7, which are respectively installed on both sides of the cylindrical guide rail 6. One side is fixed by the cylindrical head of the cylindrical guide rail 6, and the other side is fixed by the inner corner thin nut 24. A steel sleeve 16 is installed between the lower die sliding seat 2 and the cylindrical guide rail 6 . The two cylindrical guide rail seats 7 define the movement path of the lower die sliding seat 2 . The hexagon head bolts 28 fix the lower die 1 on the lower die sliding seat 2 through the compression nut 10, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com