Combined member for packaging plate glass

A technology of flat glass and combined components, which is applied in the direction of special packaging, packaging, transportation and packaging, etc. It can solve the problems of glass damage, reduce the strength of the top cover, and balance the stress of the flat glass group, achieving simple structure , Good lifting stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

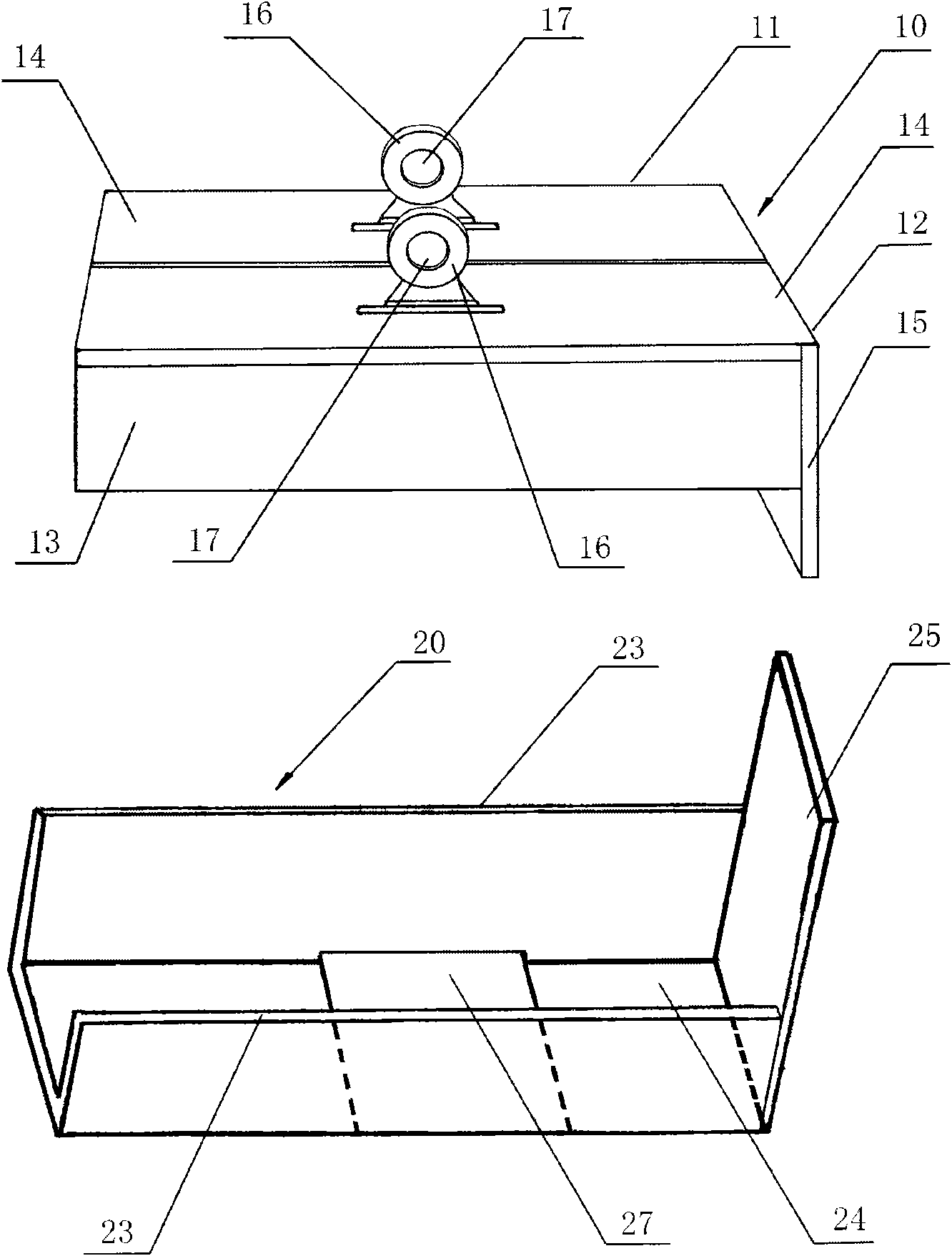

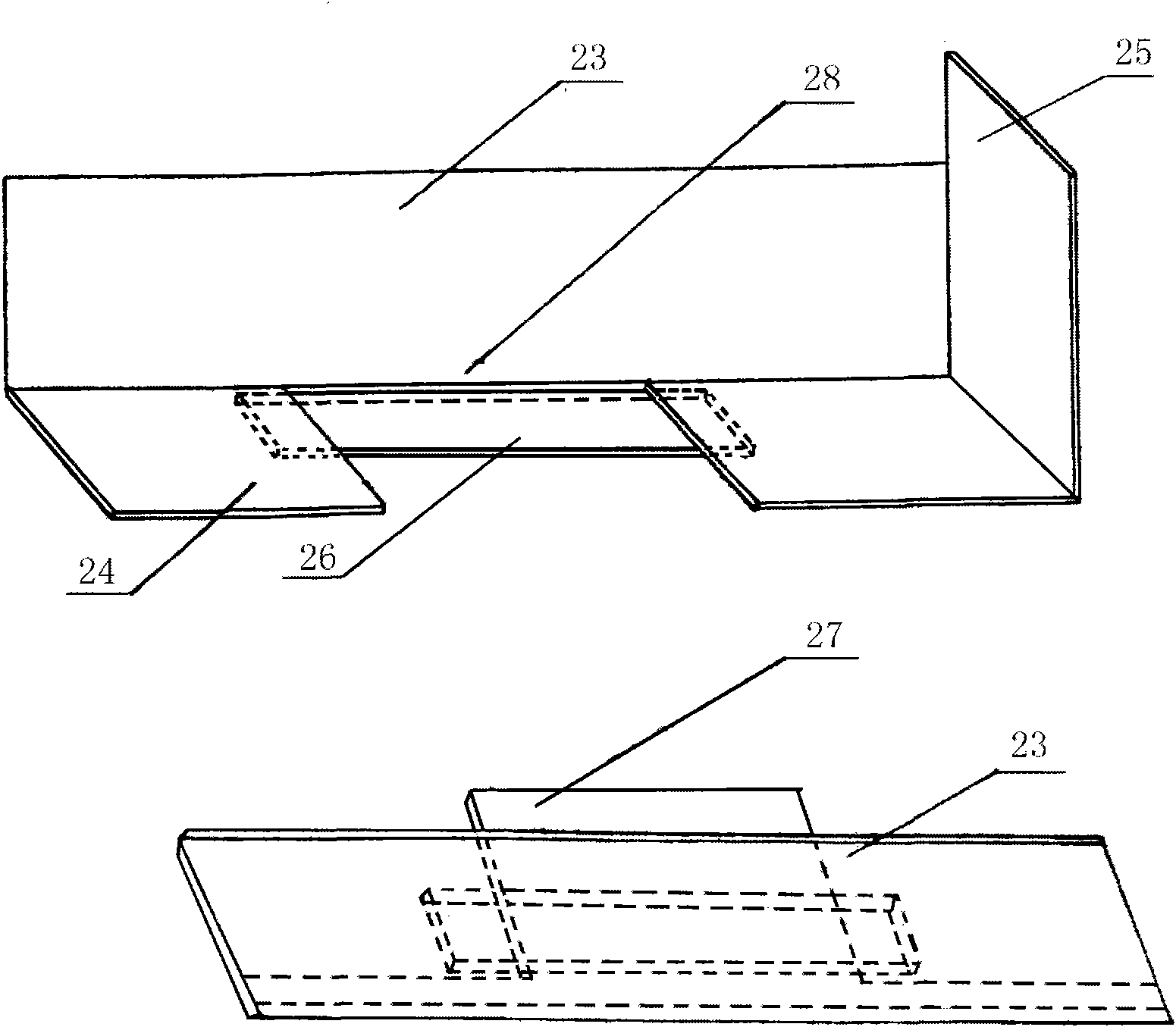

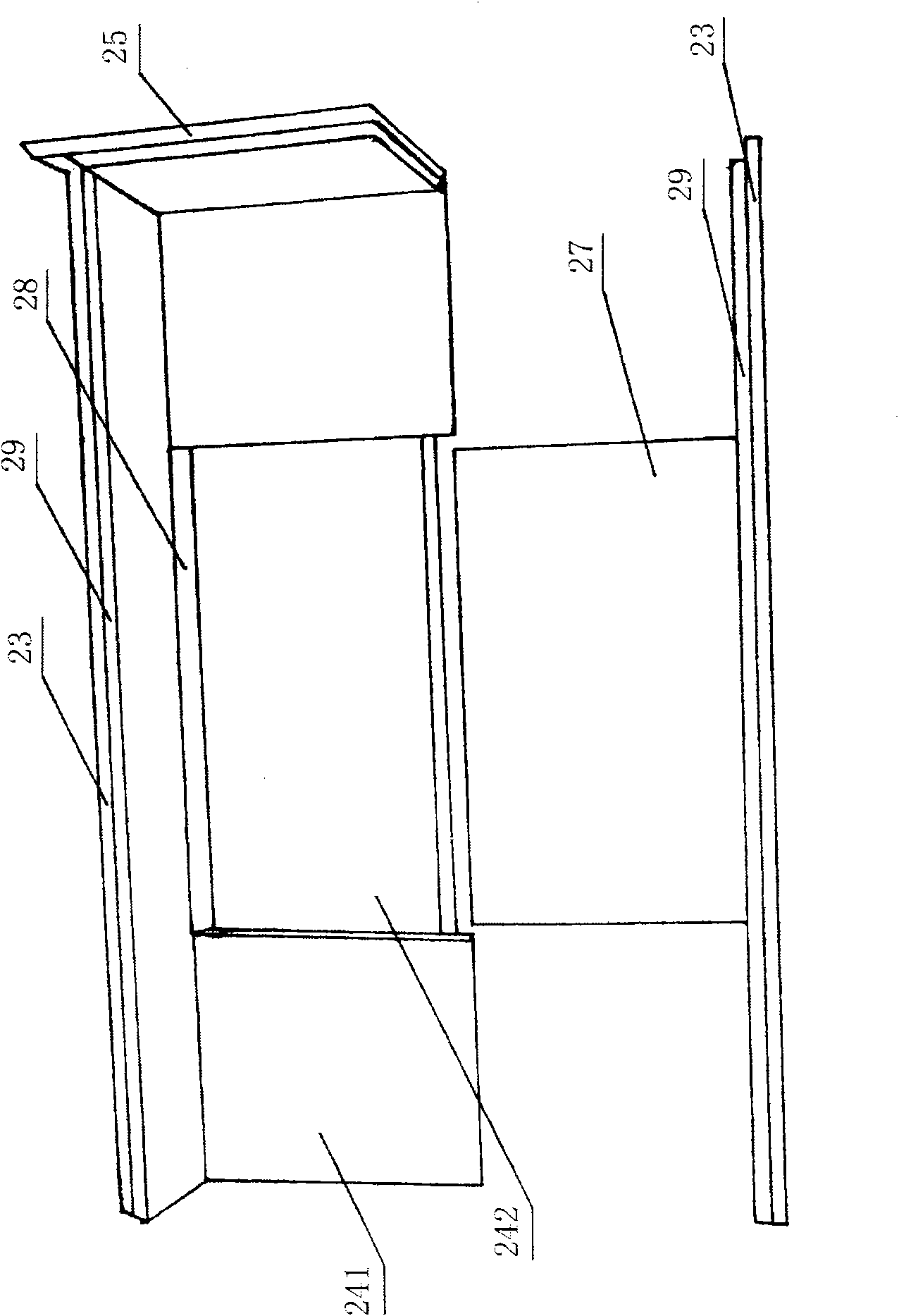

[0022] Such as figure 1 As shown, the flat glass package combination member described in the embodiment of the present invention includes a top cover 10 and a base 20 .

[0023] Both the top cover 10 and the base 20 are made of metal materials such as steel plate, iron plate or aluminum plate. It can be stamped and formed in one piece, or it can be welded. For example, when steel plates are used, they can be welded with steel plate profiles. Preferably, the top cover 10 and the base 20 are welded by steel plates.

[0024] Wherein, the top cover 10 further includes two symmetrical parts, namely a left half 11 and a right half 12 . Each part further includes a side plate 13, a base plate 14 and a baffle plate 15 punched out from a steel plate profile, one side of the side plate 13 is welded to the base plate 14, and one end of the side plate 13 and the base plate 14 is connected to the base plate 14. The baffle plate 15 is connected by welding, and each part of the base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com