Method for preparing BaFe12O and BaTiO3 multiplayer nano compound film/powder

A bafe12o19 and nanocomposite technology, which is applied in the field of nanocomposite film/powder preparation, can solve the problems of poor film compactness and poor electromagnetic performance, and achieve the effects of improving wave absorption performance, reducing cost and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] BaFe of the present invention 12 o 19 with BaTiO 3 Not only can it be configured in any molar ratio according to actual needs, but also the BaFe prepared by the present invention 12 o 19 and BaTiO 3 The number M of layers of the nanocomposite film can also be configured arbitrarily according to actual needs. Wherein, the value range of M is: M≥1.

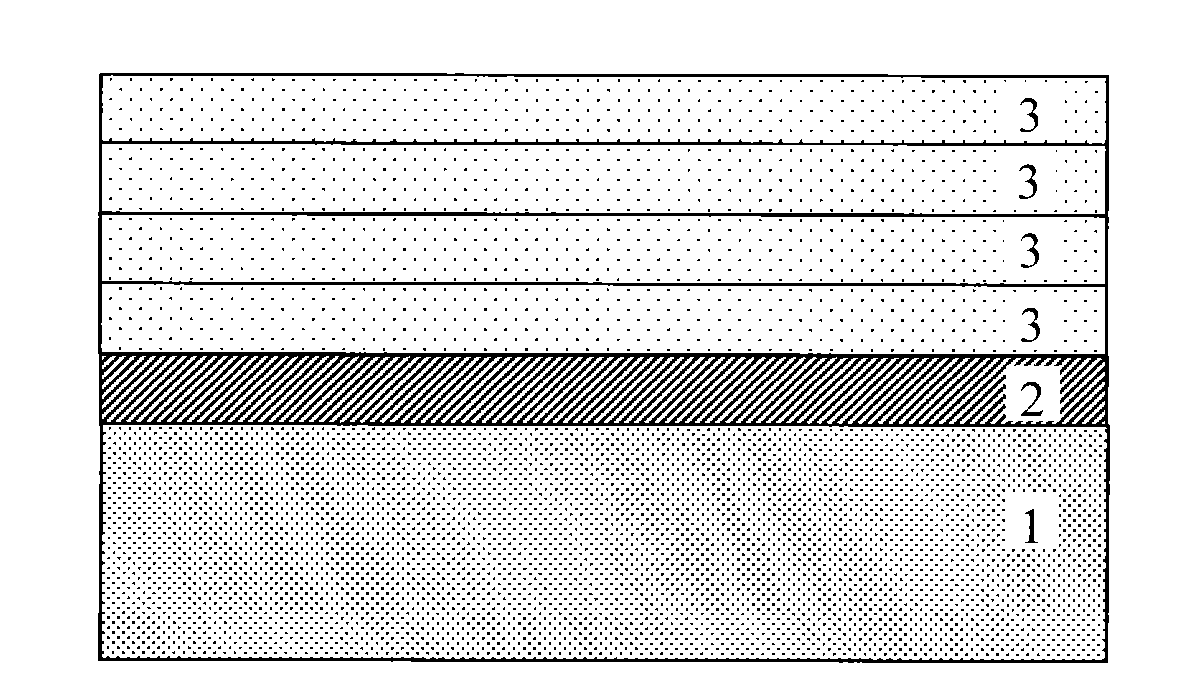

[0032] Such as figure 1 BaFe with the number of layers M=4 shown 12 o 19 with BaTiO 3 nanocomposite film, the BaFe 12 o 19 and BaTiO 3 The molar ratio is 95:5. It can be seen from the figure that the composite thin film consists of substrate 1, seed layer 2, and four layers of BaFe with a molar ratio of 95:5. 12 o 19 with BaTiO 3 The composition of the nanocomposite film 3 .

[0033] The concrete steps of preparing this kind of composite film are as follows:

[0034] (1) Weigh or measure Ba(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, C 6 h 8 o 7 and (C 6 h 9 NO) n ; Wherein, the value range of X is: 0.5≤X≤1, an...

Embodiment 2

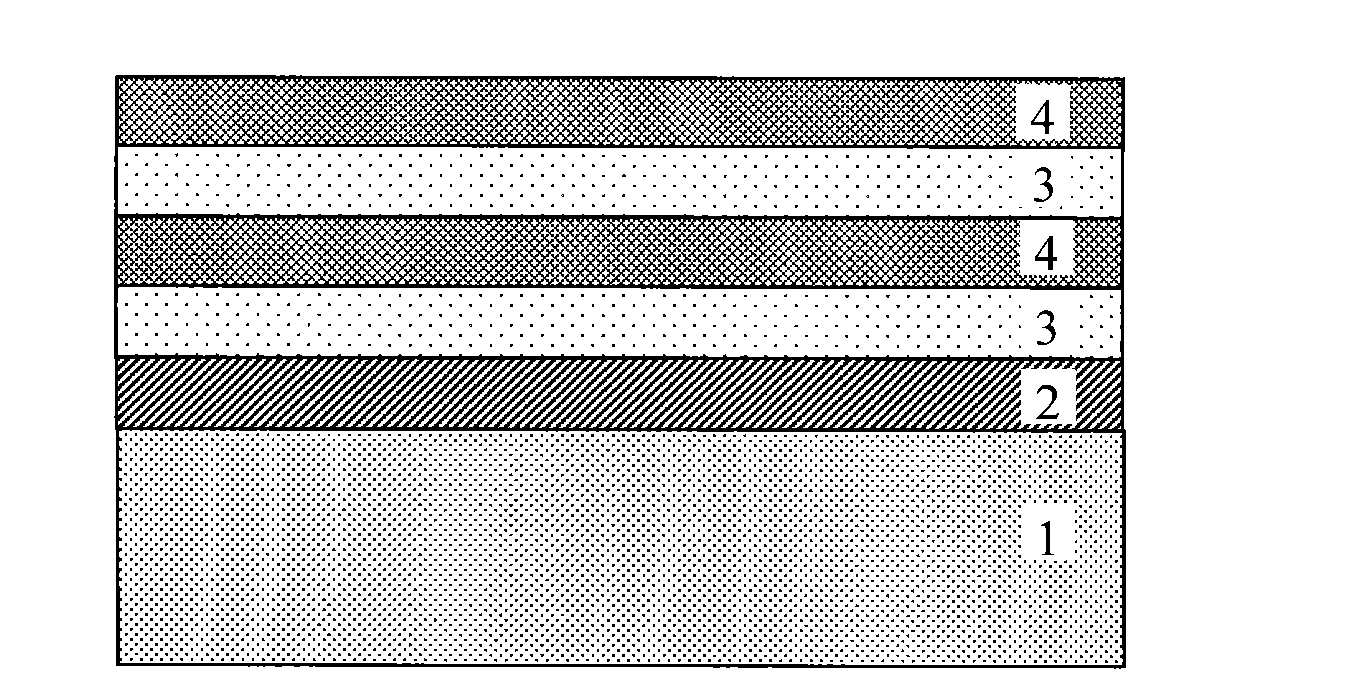

[0048] figure 2 shows the number of layers M=4, and BaFe 12 o 19 with BaTiO 3 Schematic diagram of the structure of alternating nanocomposite films with molar ratios of 95:5 and 90:10, respectively. It can be seen from the figure that the film is sequentially composed of substrate 1, BaFe with a molar ratio of 95:5 12 o 19 and BaTiO 3 The seed layer 2, BaFe with a molar ratio of 95:5 12 o 19 and BaTiO 3 Composite film 3, BaFe with a molar ratio of 90:10 12 o 19 and BaTiO 3 Composite film 4, BaFe with a molar ratio of 95:5 12 o 19 and BaTiO 3 Composite thin film 3, and BaFe with a molar ratio of 90:10 12 o 19 and BaTiO 3 Composite film 4 constitutes.

[0049] The concrete steps of preparing this four-layer alternating nanocomposite film are as follows:

[0050] The steps and other conditions of (1), (2) are all the same as in Example 1, and the difference is only in:

[0051] (3) by BaFe 12 o 19 with BaTiO 3 The molar ratios are 95:5 and 90:10 respectivel...

Embodiment 3

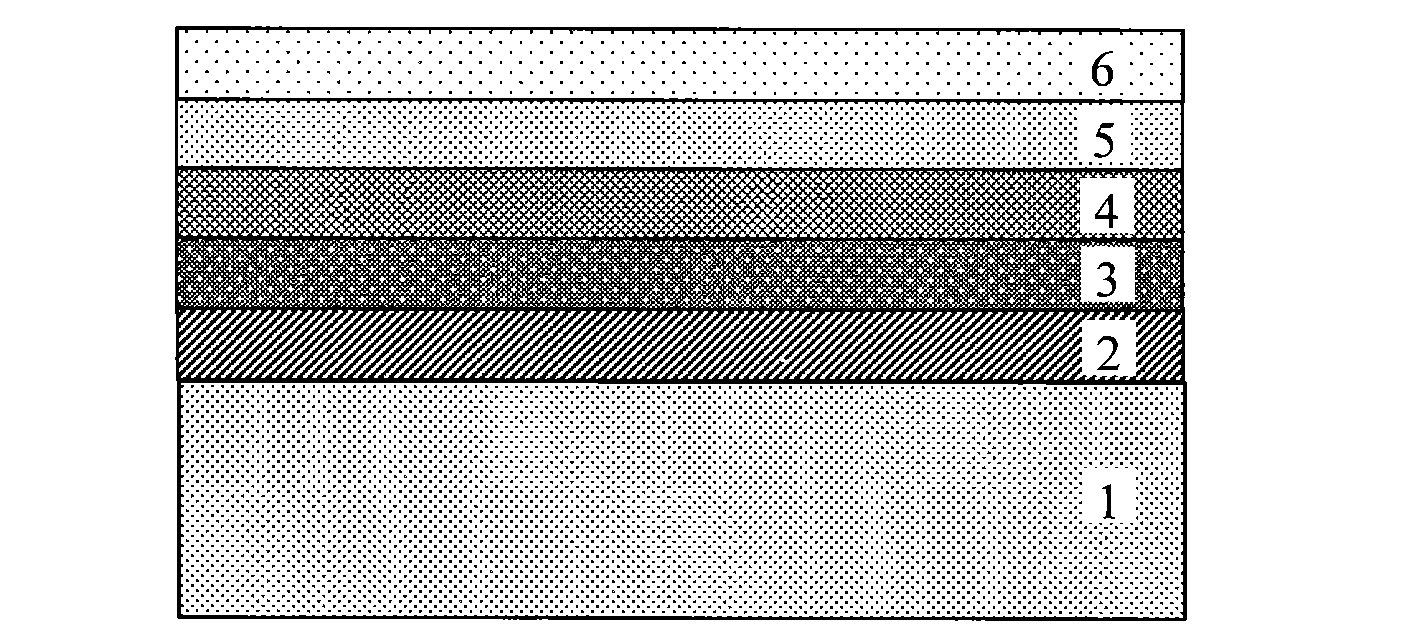

[0057] image 3 shows the number of layers M=4, on BaFe 12 o 19 with BaTiO 3 Schematic diagram of the structure of the nanogradient composite film with molar ratios of 100:5, 100:10, 100:15 and 100:20, respectively. It can be seen from the figure that the film is sequentially composed of substrate 1, BaFe with a molar ratio of 100:5 12 o 19 and BaTiO 3 The seed layer 2, BaFe with a molar ratio of 100:5 12 o 19 and BaTiO 3 Composite film 3, BaFe with a molar ratio of 100:10 12 o 19 and BaTiO 3Composite film 4, BaFe with a molar ratio of 100:15 12 o 19 and BaTiO 3 Composite thin film 5, and BaFe with a molar ratio of 100:20 12 o 19 and BaTiO 3 Composite film 6 constitutes.

[0058] The steps and other conditions for preparing this kind of film are all the same as in Example 2, the only difference is that in step (3), it is necessary to prepare four parts with molar ratios of 100:5, 100:10, 100:15 and 100: 20BaFe 12 o 19 and BaTiO 3 Composite sol; In step (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com