Prefabricated part for loading bridge supporting bracket

A technology of prefabricated components and support frames, which is applied in the fields of bridge engineering and civil engineering, can solve the problems of prolonging the time of sealing roads, small sand specific gravity, and unsafety, etc., and achieve the effect of reducing traffic time, ensuring integrity, and reducing the number of installation pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

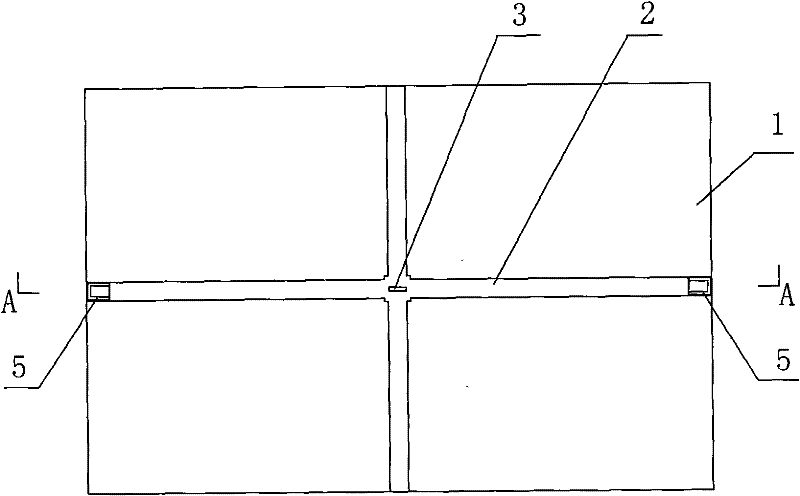

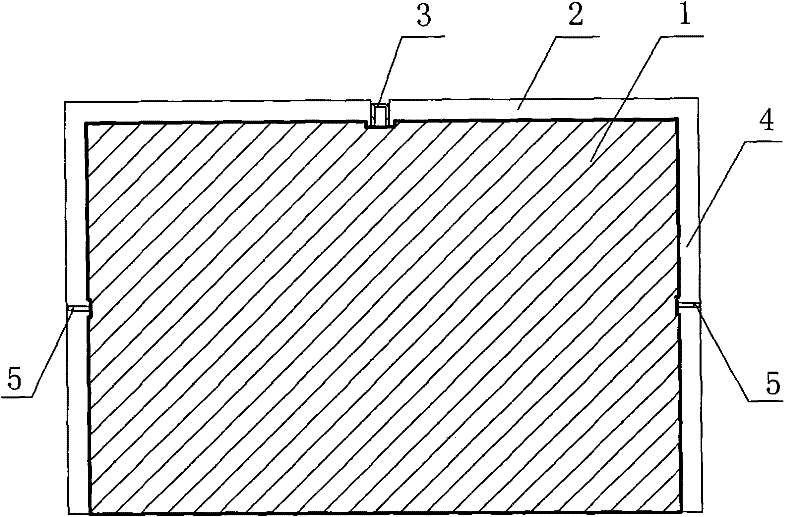

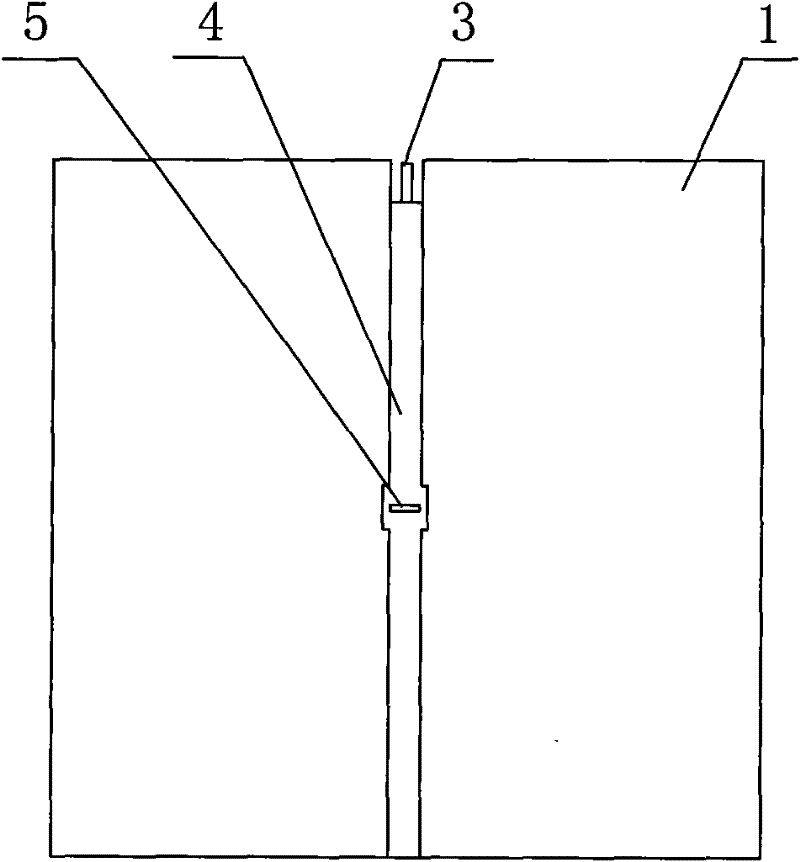

[0028] Such as figure 1 , figure 2 , image 3 As shown, the prefabricated component used to load the bridge support frame includes a block-shaped prefabricated component 1; the upper surface of the prefabricated component is provided with vertical and horizontal grooves 2, and the intersection of the horizontal grooves 2 is fixed with a first The hook 3; the side of the prefabricated component is provided with a vertical groove 4, and the second hook 5 is fixed in the vertical groove 4.

[0029] The material of the prefabricated component is concrete; it is prefabricated according to existing conventional methods. The length of the prefabricated component is 1.2m, the width is 1.2m, and the height is 0.8m.

[0030] Application: A method for loading a bridge support frame with prefabricated components, which includes the following steps:

[0031] 1) if figure 1 , figure 2 , image 3 As shown, the prefabricated component 1 is made, and the prefabricated component is blo...

Embodiment 2

[0037] Such as Figure 4 , Figure 5 As shown, it is basically the same as Embodiment 1, except that the lower surface of the prefabricated component is provided with a first chute 6 and a second chute 8, and the first chute 6 and the second chute 8 are arranged in parallel , the first chute 6 and the second chute 8 are equipped with at least two rollers 7; the upper surface of the prefabricated component is provided with a first guide bar 9 and a second guide bar 10, and the first guide bar 9 and the first slide The position of the groove 6 is corresponding, and the second guide bar 10 is corresponding to the position of the second chute 8 (the spacing between the first guide bar 9 and the second guide bar 10 is the same as that of the first chute 6 on the lower surface of the prefabricated component. Consistent with the spacing between the second chute 8; the roller 7 in the first chute 6 on the lower surface of the prefabricated component of the upper layer falls on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com