Movable type scaffold bracket for overhead construction of building engineering

A technology for high-altitude construction and construction engineering, which is used in buildings, building structures, scaffolding supported by building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

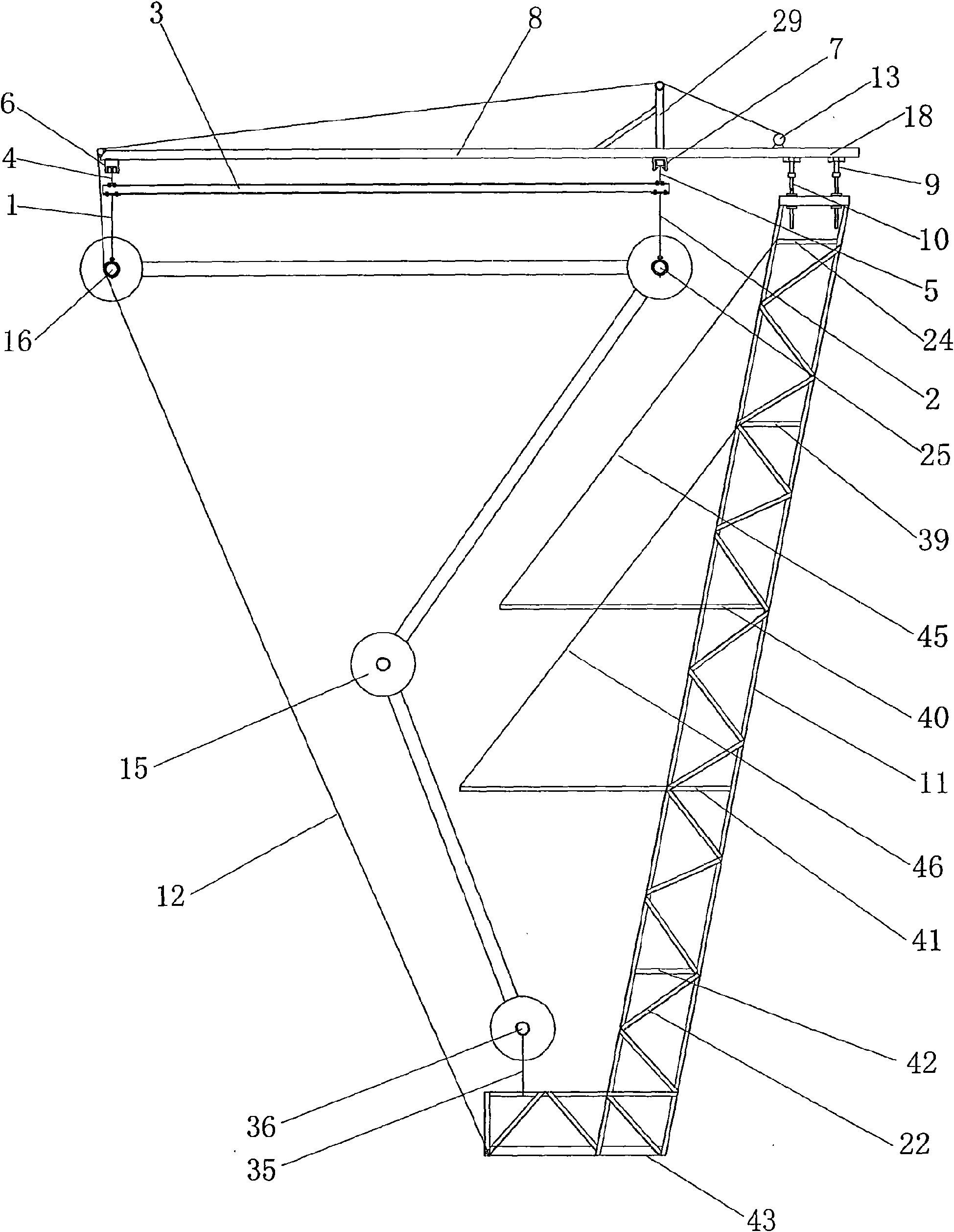

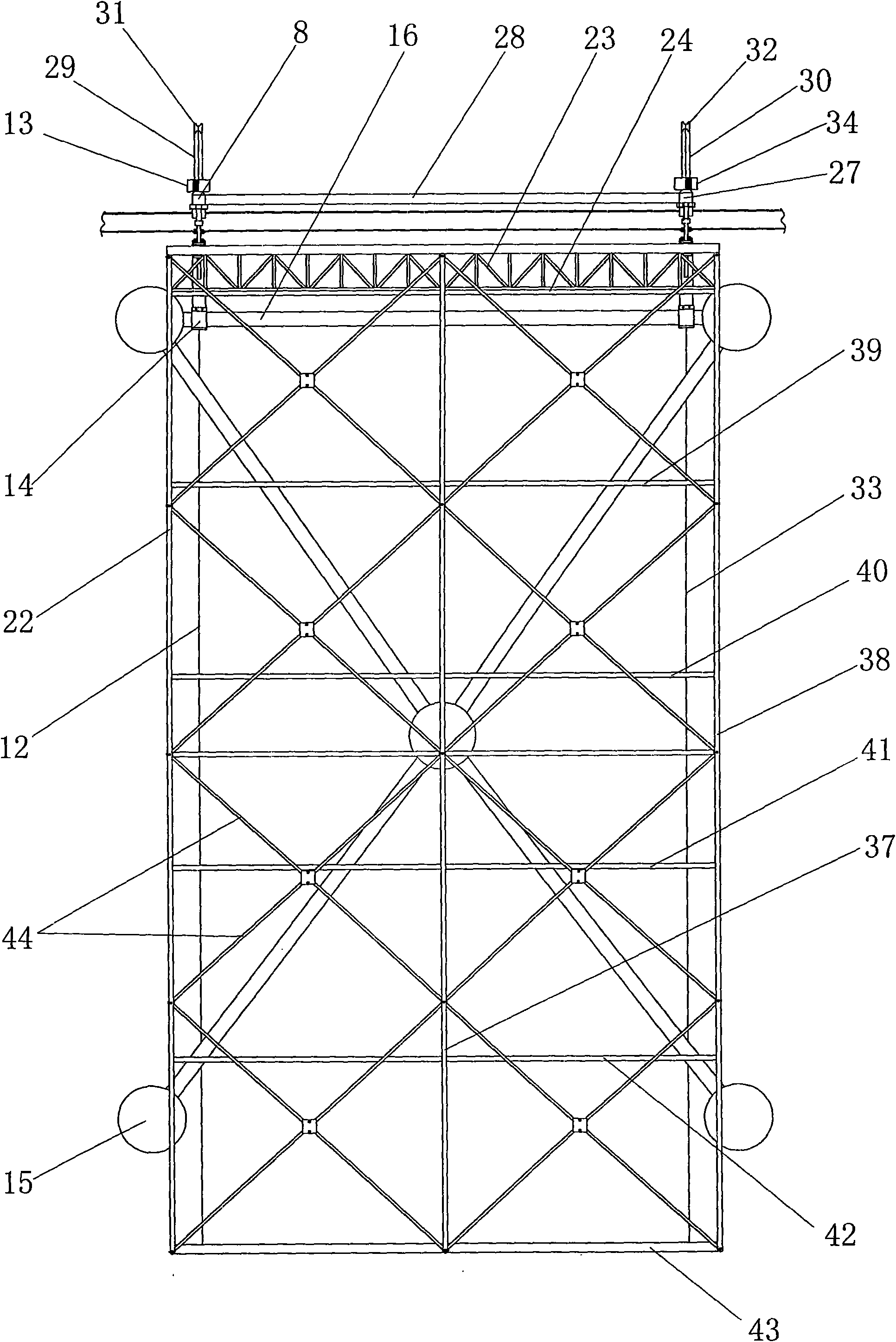

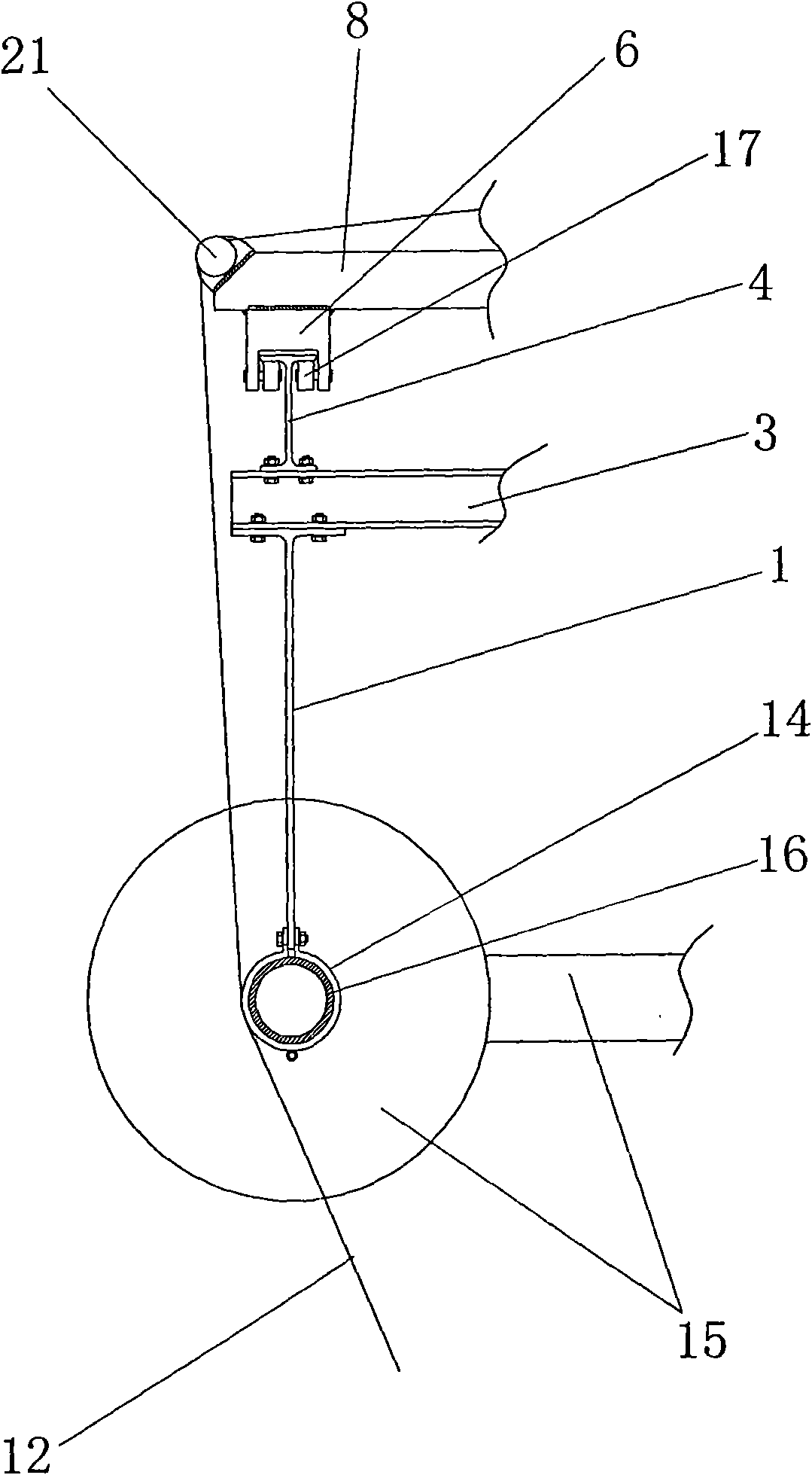

[0022] refer to Figure 1 to Figure 5 , the movable pick frame used for high-altitude construction in this construction project is characterized by: including pillars 1, 2, etc., beams 3, etc., guide rails 4, 5, rollers 6, 7, etc., main beams 8, etc., and outer hanger wires Rod 9, etc., inner hanger screw rod 10, etc., pick frame 11, steel wire rope 12, etc., winch 13, etc., wherein the lower ends of pillars 1, 2, etc. are fixedly connected to the top cross bar 16 of steel grid frame 15 through hoops 14, etc. etc., the crossbeam 3 etc. are fixedly connected on the pillars 1, 2 etc., the guide rails 4, 5 are fixedly connected on the crossbeam 3 etc., the rollers 6, 7 etc. are respectively rolled and matched with the guide rails 4, 5 through the rollers 17 etc. on them, The main beam 8 etc. are fixedly connected to the rollers 6, 7 etc., and the upper parts of the inner and outer hanger screw rods 10, 9 etc. are respectively fixedly connected to the outer end sections 18 etc. of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com