Core sampler with controlled cooling water

A technology for core sampling and cooling water, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of wasting water resources and inconvenient operators, and achieves the effects of convenient operation, saving water resources and reducing development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

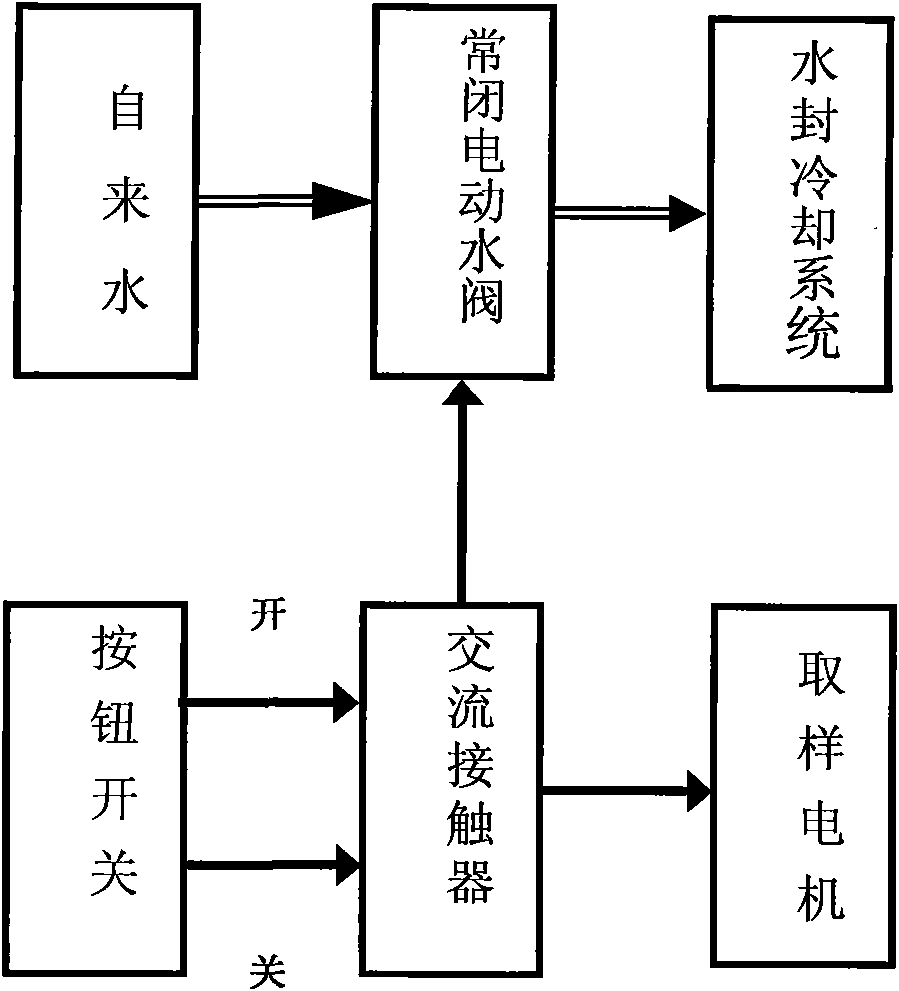

[0008] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention consists of a sampling motor, a button switch, an AC contactor, a water-sealed cooling system and a normally closed electric water valve. The controlled AC contactor is respectively connected to the normally closed electric water valve and the power supply end of the sampling motor. If the AC contactor is not connected, the sampling motor does not work, the normally closed solenoid valve is in a closed state, and the cooling water (tap water) is blocked. Carry out sample loading, adjustment, etc. When the "on" button switch is pressed, the AC contactor is connected, the sampling motor works, the normally closed electric water valve is in the open state, and the cooling water enters the water-sealed cooling system for normal sampling work. When a sample is taken, press the "off" button switch, the AC contactor is disconnected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com