Self-sucking type oil mist sealing purifier

A purification device, self-priming technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor effect, waste of energy, leakage of oil mist in the gap, etc., and achieves ingenious design structure and technical Good effect, easy to produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

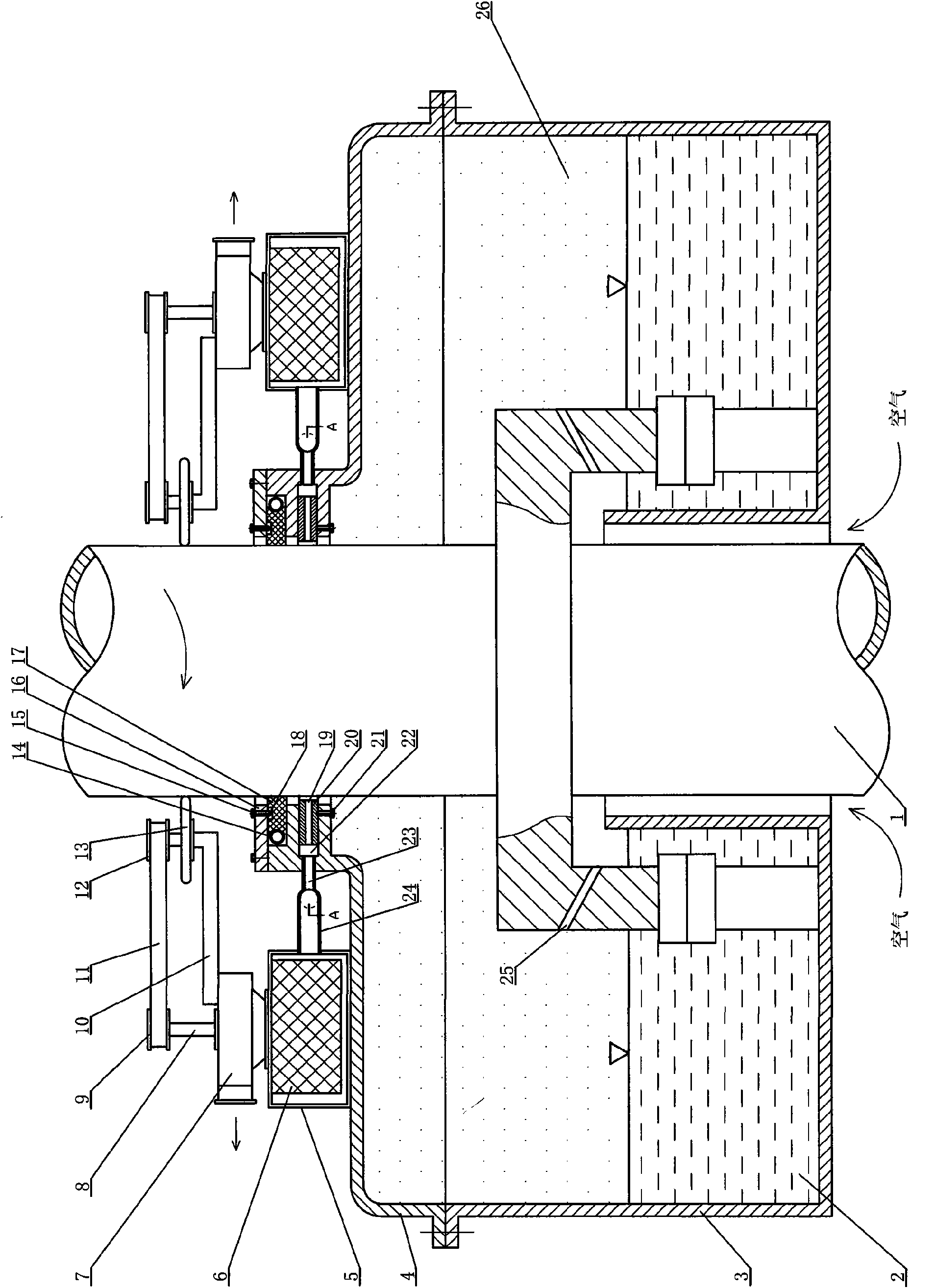

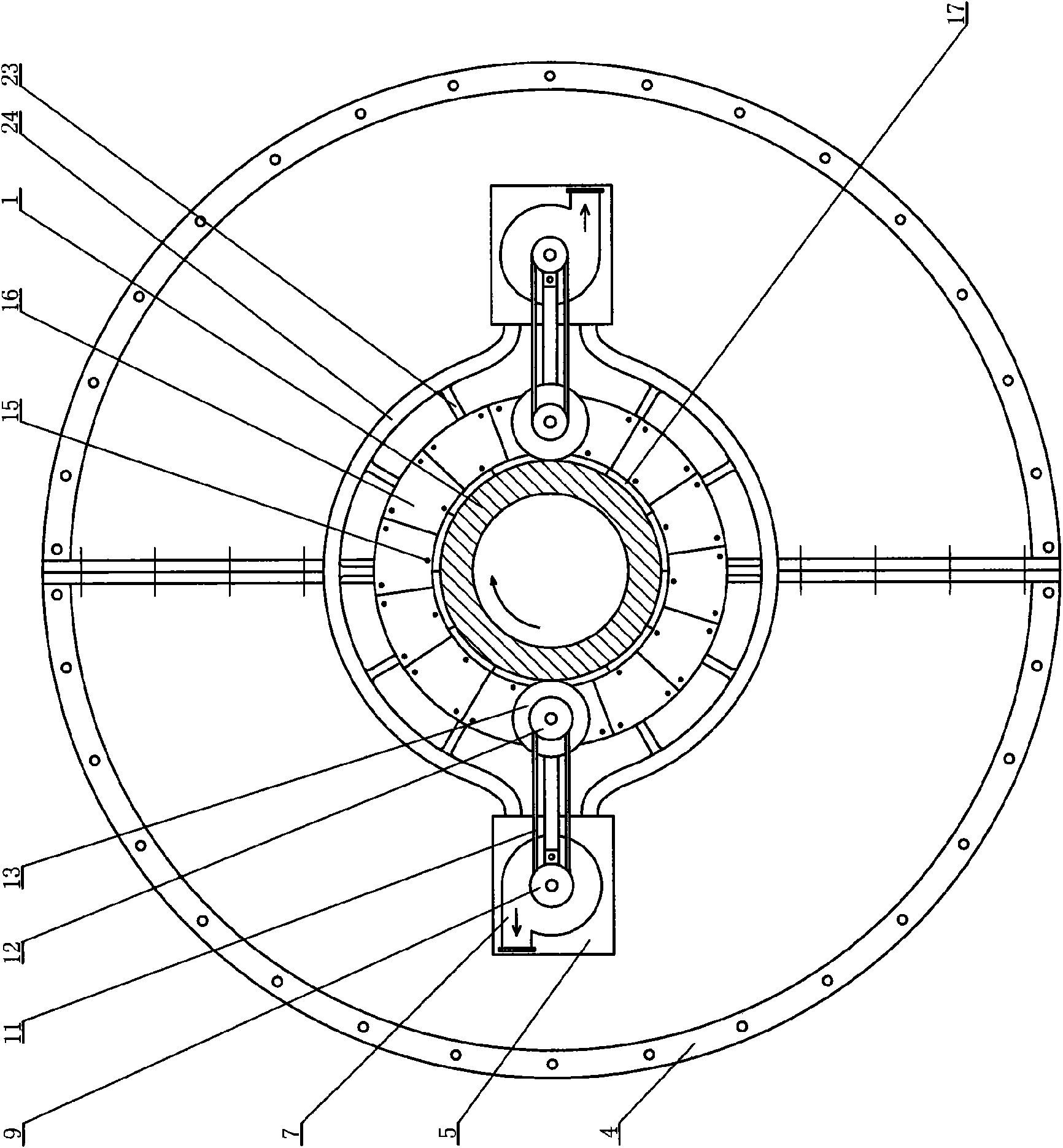

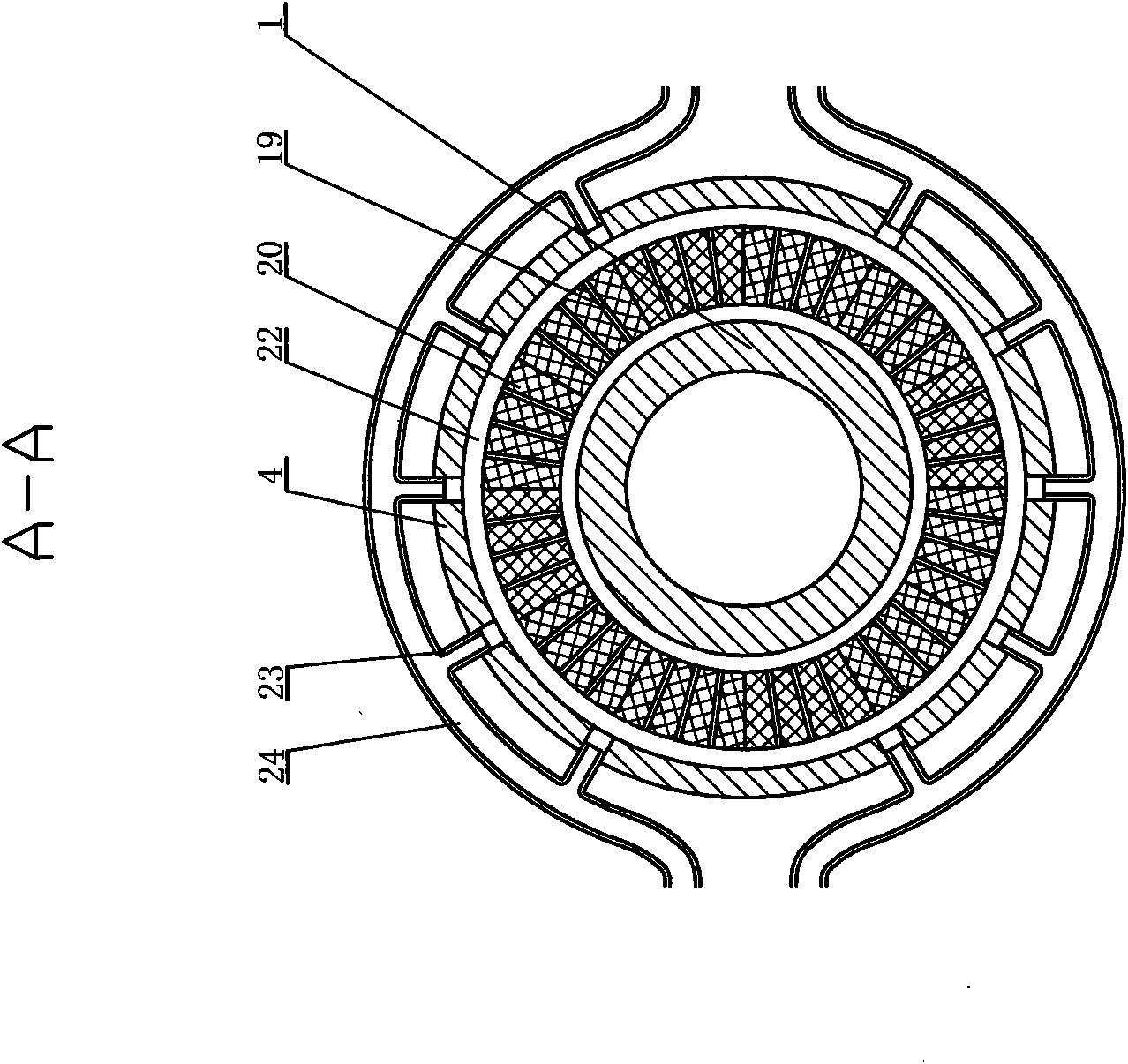

[0020] Put the split carbon orifice plate (20) into the ring-shaped oil-absorbing mist groove (22) on the oil tank cover (4) divided into two large petals, and use multiple positioning bolts (21) to fix the split carbon orifice plate ( 20) Carry out withstanding positioning, so that the distance between the inner diameter and the surface of the main shaft (1) is the best. Two petals of oil tank covers (4) are centered on the main shaft (1) to form a circle. Use multiple branch oil suction mist pipes (23) to connect the ring type oil suction mist tank (22) with the main ring type oil suction mist pipe (24), and then connect the main ring type oil suction mist pipe (24) with the oil filter housing ( 5) Internal communication, oil filter mist (6) is installed inside the oil filter housing (5), fan (7) is installed on the oil filter housing (5), and communicated with the oil filter mist (6) . The vane shaft (8) of the blower fan (7) is fixed together with the synchronous wheel (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com