Backlight unit and test method thereof, liquid crystal module and test method thereof

A technology of a backlight unit and a testing method, applied in optics, nonlinear optics, instruments, etc., can solve problems such as cumbersome operation, achieve the effect of simple replacement operation and save time for optical index optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

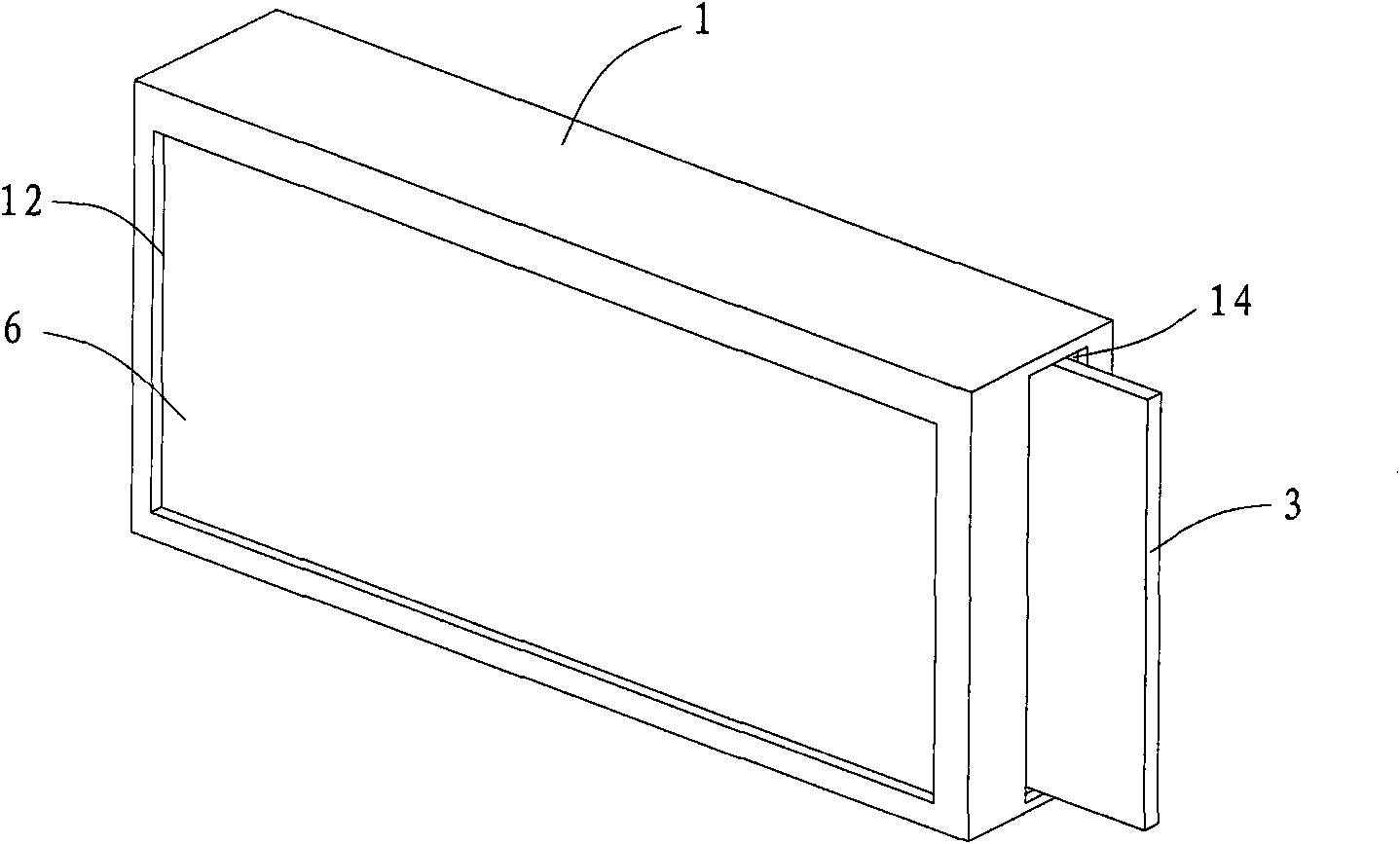

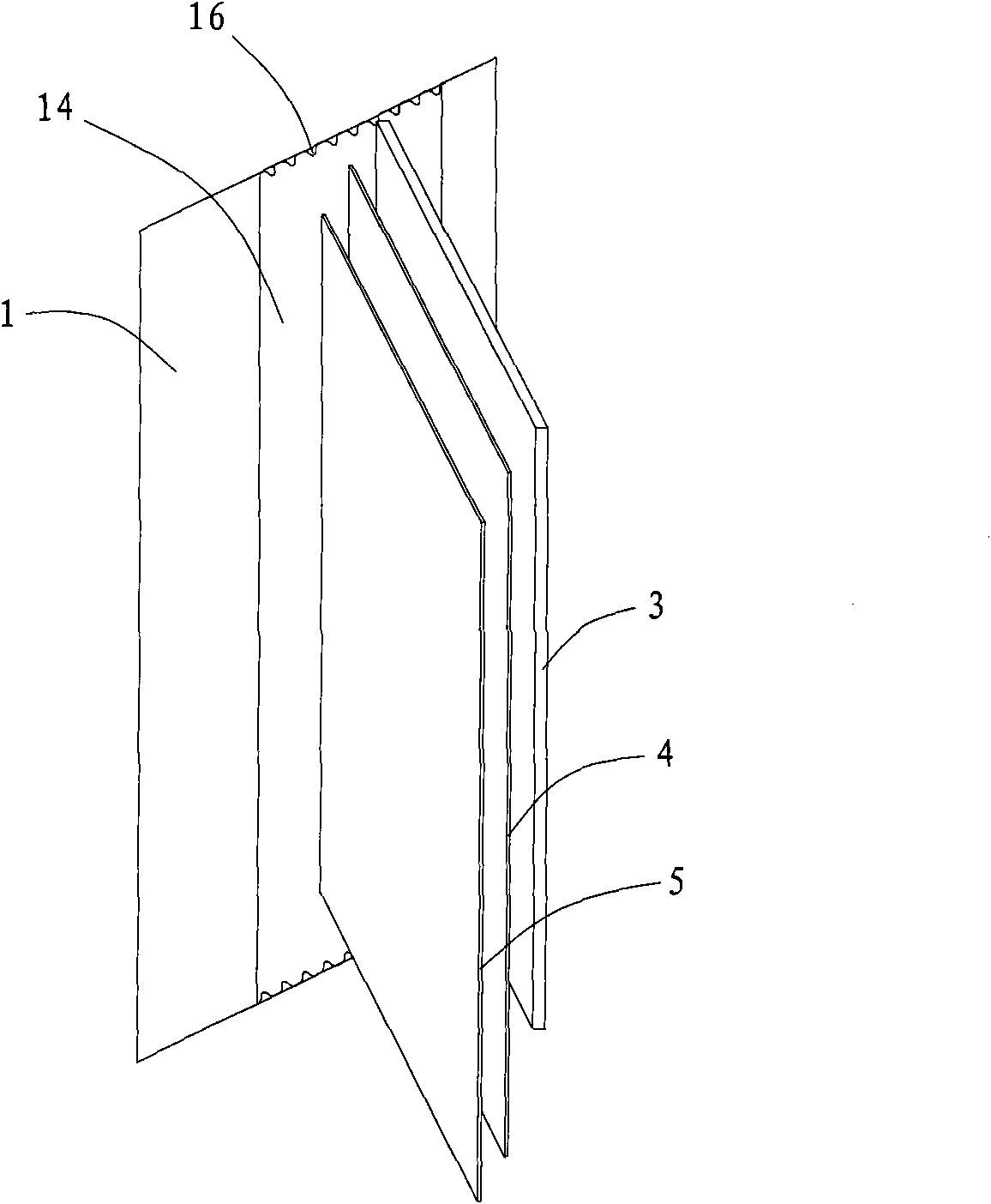

[0041] like figure 2 As shown, it is a specific embodiment of the backlight unit of the present invention. In this embodiment, the backlight unit includes a middle frame 1, the middle frame 1 has a first groove 12, and an optical film is arranged in parallel in the first groove 12. sheet and the liquid crystal panel 6, the diffusion plate 3 is shown in the figure, the light transmitted by the optical film can enter the liquid crystal panel 6, and the first slit 14 is arranged at the position corresponding to the optical film in the first groove 12, the optical film The film is taken out from the middle frame 1 through the first slit 14 , or the optical film is inserted into the middle frame 1 through the first slit 12 .

[0042] like image 3 As shown, in the backlight unit in this embodiment, since each optical film can be taken out from the middle frame 1 or inserted into the middle frame 1 through the first slit 14, the optical film can be replaced by this method without ...

Embodiment 2

[0050] like Figure 4 As shown, it is an embodiment of the backlight unit testing method of the present invention. The structure and function of the backlight unit in this embodiment are the same as the structure and function of the backlight unit in Embodiment 1. Wherein, the backlight unit testing method includes:

[0051] Step 101, taking out the original optical film from the middle frame through the first slit;

[0052] Step 102, inserting a new optical film into the middle frame through the first slit;

[0053] Step 103, turn on the backlight source, and test the optical index of the backlight unit under the action of the new optical film.

[0054] In the backlight unit testing method in this embodiment, since the optical film can be taken out from the middle frame through the first gap or inserted into the middle frame, the optical film can be replaced by this method without The middle frame and the liquid crystal panel need to be dismantled, and the whole replacemen...

Embodiment 3

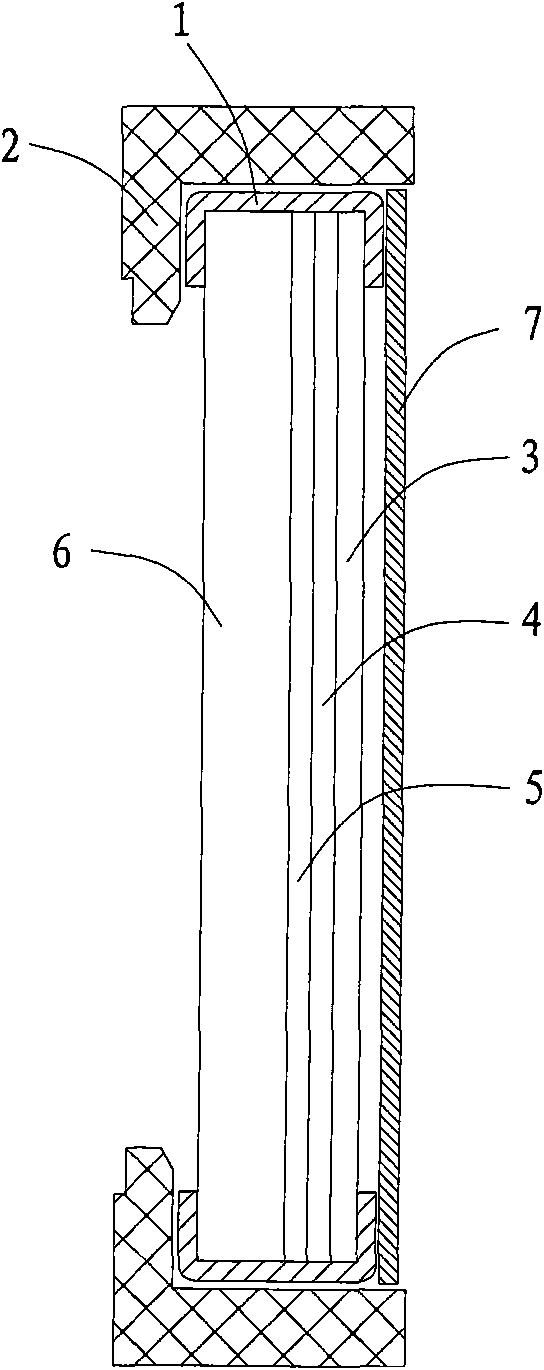

[0066] like Figure 7 As shown, it is a specific embodiment of the liquid crystal module of the present invention. In this embodiment, the liquid crystal module includes a front frame 2, and the front frame 2 has a second groove (not shown), and the second groove is provided with backplane (see figure 1 ), a middle frame 1 is arranged on the back panel. combine figure 2 As shown, the middle frame 1 has a first groove 12, and an optical film and a liquid crystal panel 6 are arranged in parallel in the first groove 12, and the light transmitted by the optical film can enter the liquid crystal panel 6, and in the first groove A first slit 14 is provided at a position corresponding to the optical film in 12, a second slit 24 is provided at a position corresponding to the first slit 14 in the second groove, and the optical film passes through the first slit 14 and the second slit. 24 is taken out from the middle frame 1, or inserted into the middle frame 1 through the first sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com