Mechanically regulated vaporization pipe

A technology of tools and sections, applied in the field of vaporization tools and tobacco pipes, can solve the problems of increased complexity of flame filters, cost and safety issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the invention. It is, however, evident that the invention may be practiced without these specific details.

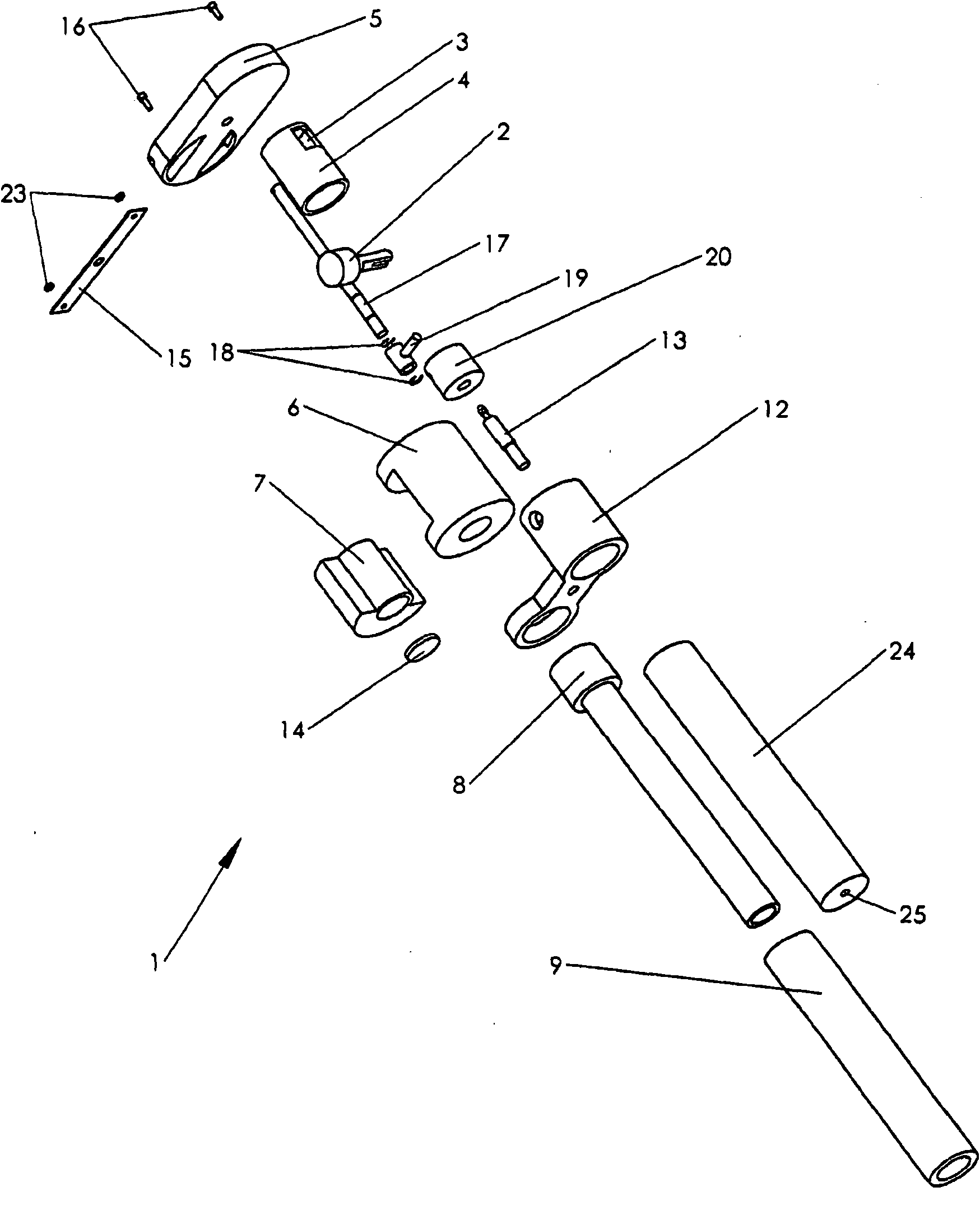

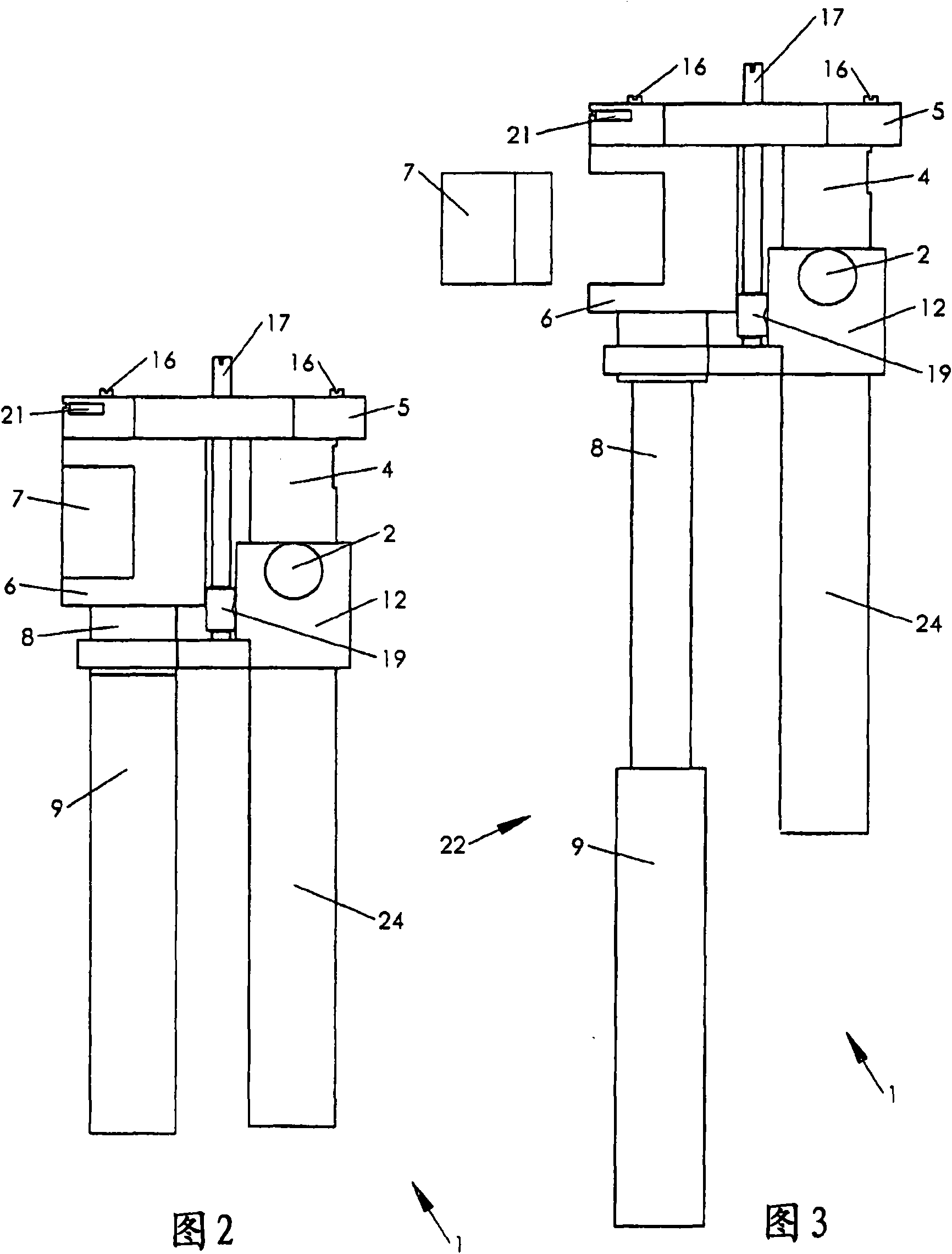

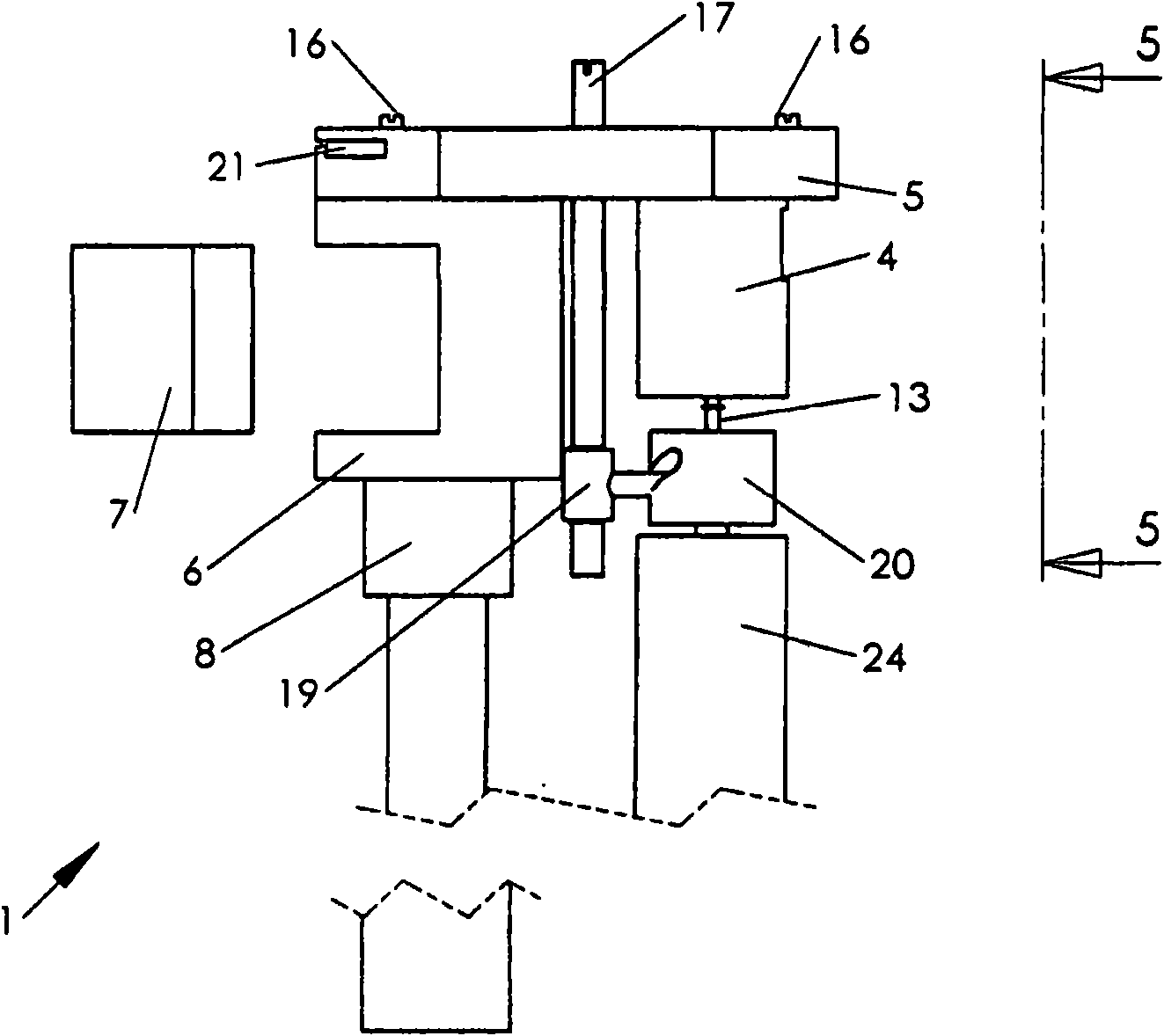

[0034] One embodiment of the present invention is in Figure 1-9 A vaporization tool generally identified by 1 in . A fuel container 24 containing fuel (eg, butane, propane) is connected to the valve assembly 13 to regulate fuel output. The conditioned fuel is combusted in the heating chamber 4 to generate heat. The temperature control inlet 5 (TCI) is in heat exchange contact with the heating chamber 4 but not in fluid contact therewith. The operator is provided with a retractable mouthpiece 22 which allows air to be inhaled. Intake air is heated as it is drawn through the FHAIC 5 . The heated air is then drawn through the smokeable material chamber 10 . The heated air and vaporized components travel through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com