Tensioner

A technology for tensioners and shaft components, applied to belts/chains/gears, mechanical equipment, transmissions, etc., which can solve problems such as unstable forward and backward movement and unstable rotation of the propulsion shaft 130

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

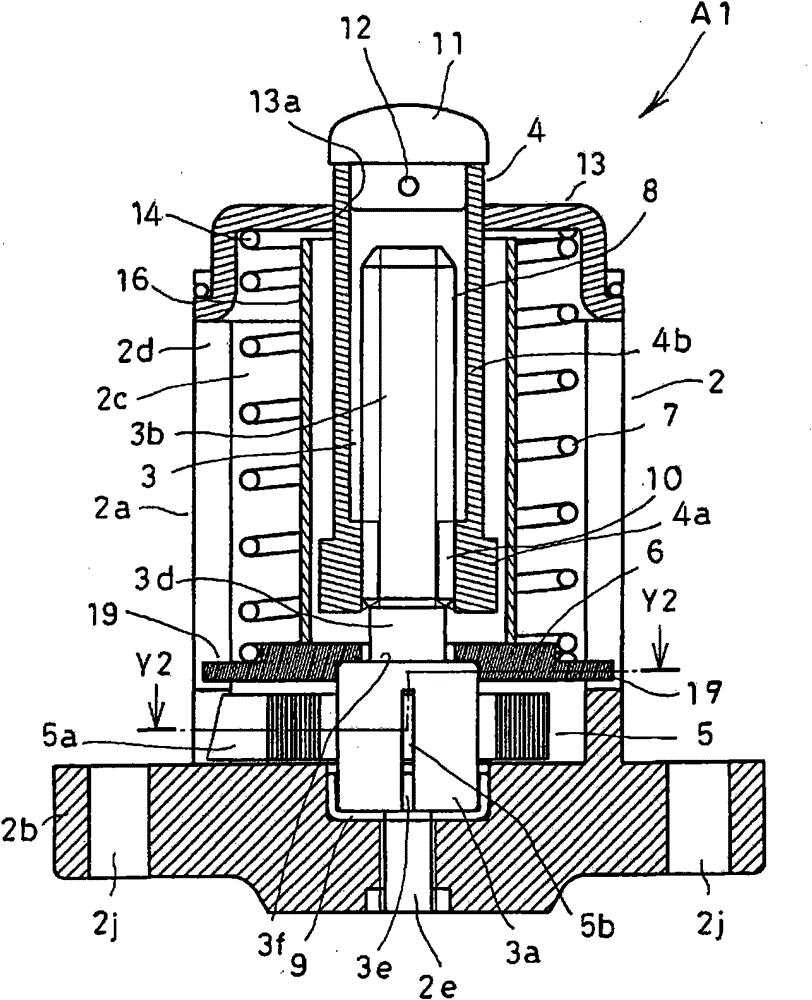

[0058] Hereinafter, the present invention will be specifically described with reference to the illustrated embodiments. In addition, in each embodiment, for the same components, the labels correspond to the same symbols.

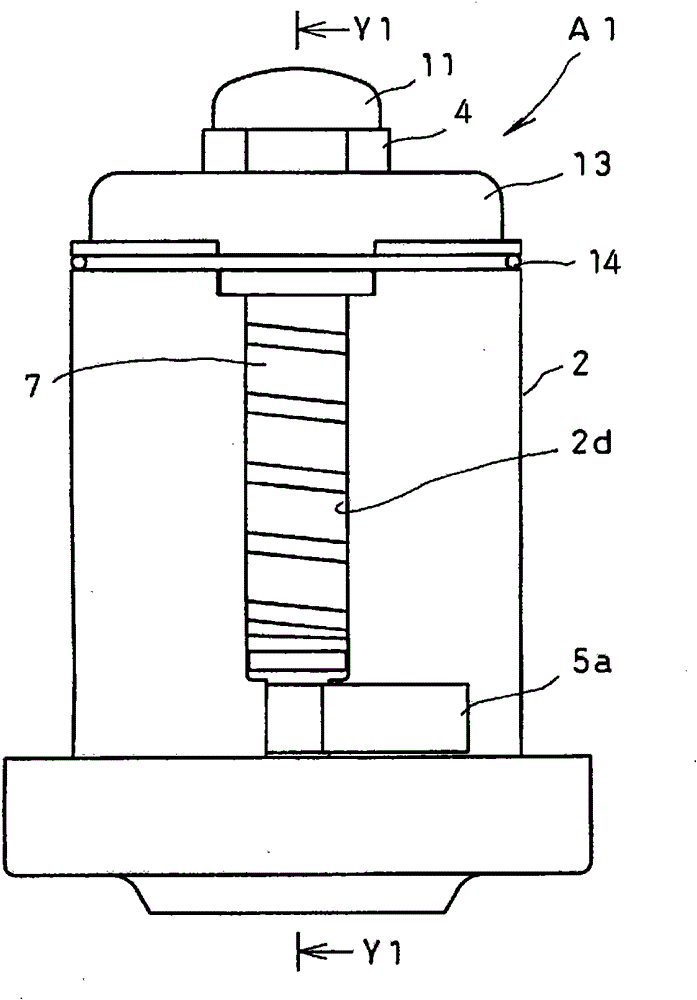

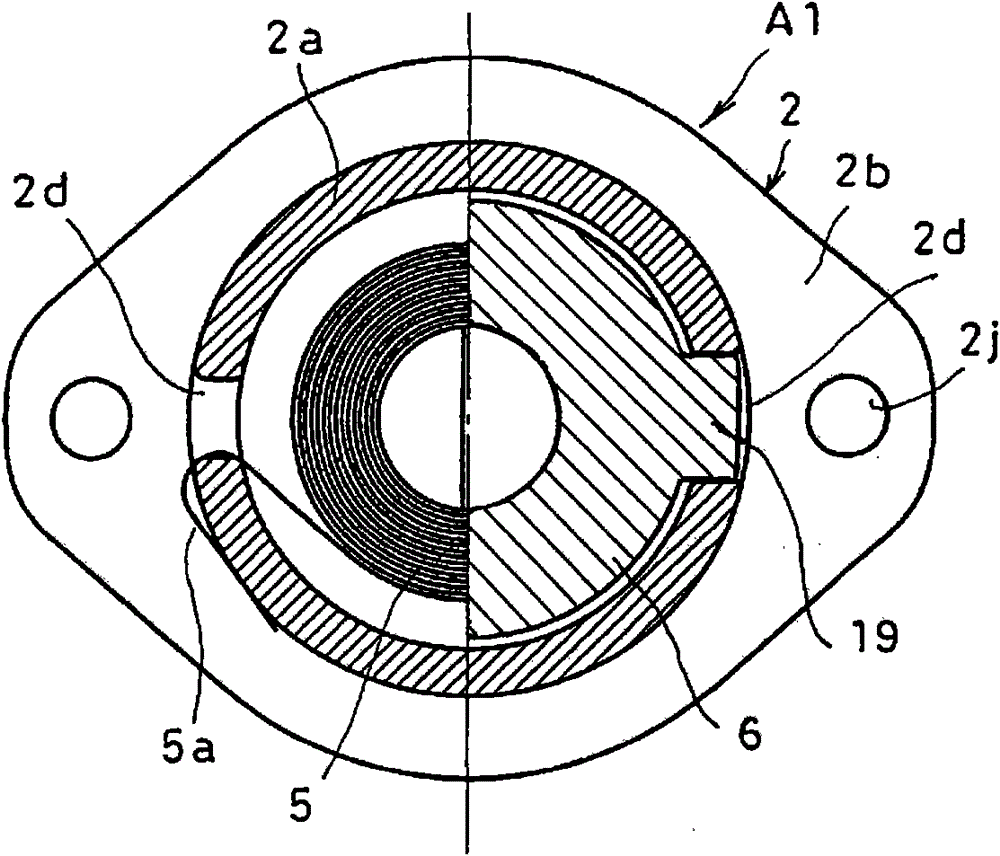

[0059] Figure 1 to Figure 4 The tensioner A1 of the first embodiment of the present invention is shown. The tensioner A1 includes a housing 2 , a first shaft member 3 , a second shaft member 4 , an urging spring 5 , a friction member 6 , and an elastic member 7 .

[0060] The housing 2 includes a main body portion 2a and a flange portion 2b. The flange portion 2b extends in a direction perpendicular to the axial direction, and the main body portion 2a extends in the axial direction from the side of the flange portion 2b. The main body part 2a is formed with the accommodation hole 2c. The front end portion of the housing hole 2c is opened, and the assembly of the first shaft member 3, the second shaft member 4, the urging spring 5, the friction member 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com