Forming device for dental floss section film stripping

A forming device and film cracking technology, applied in the direction of dental floss, etc., can solve the problems of slow elastic effect of dental floss, insufficient strength of dental floss, unsatisfactory taste, etc., and achieve the effect of good taste, convenient repair and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The slicing membrane split forming device for dental floss of the present invention will be further described in detail below with reference to the accompanying drawings.

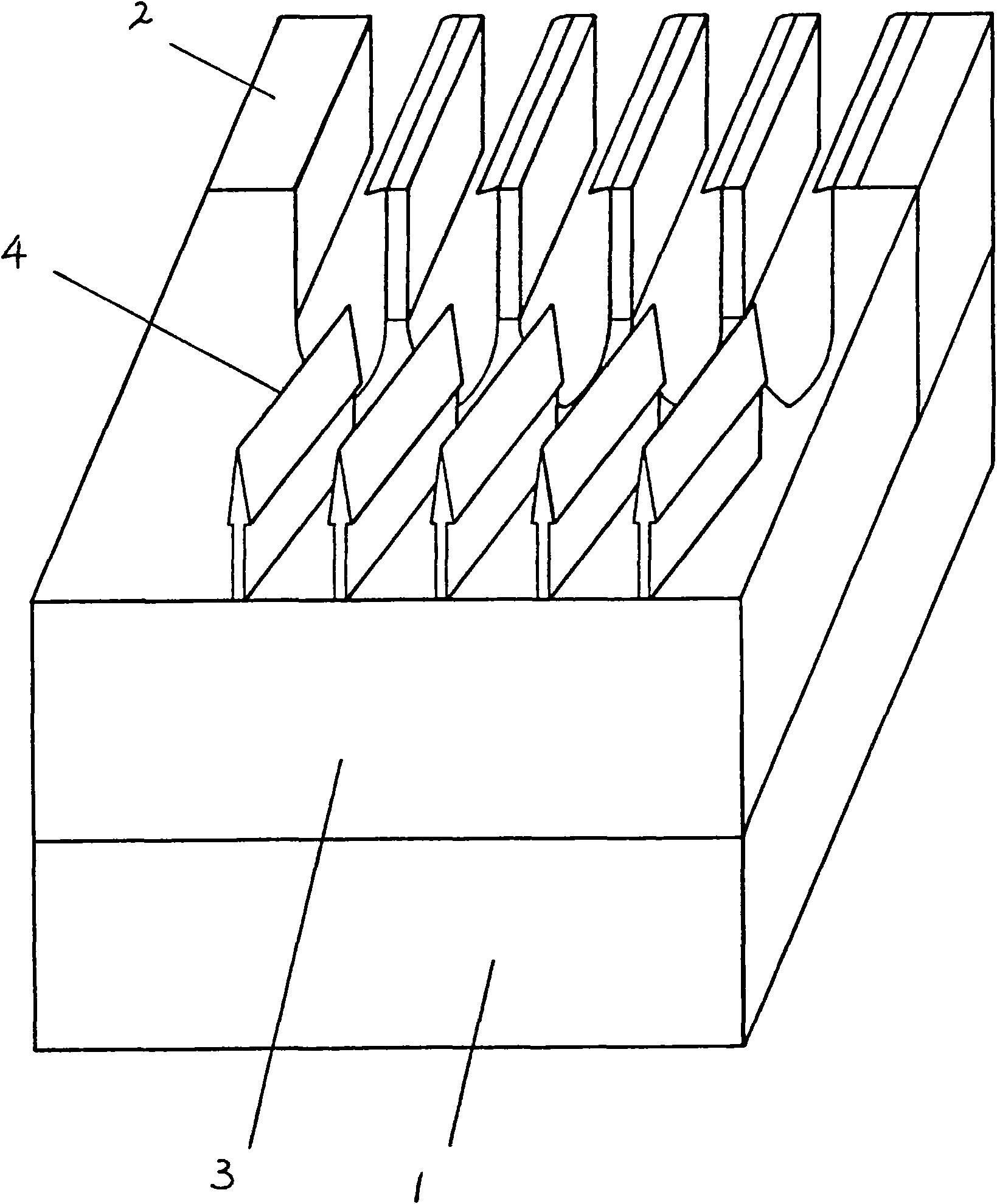

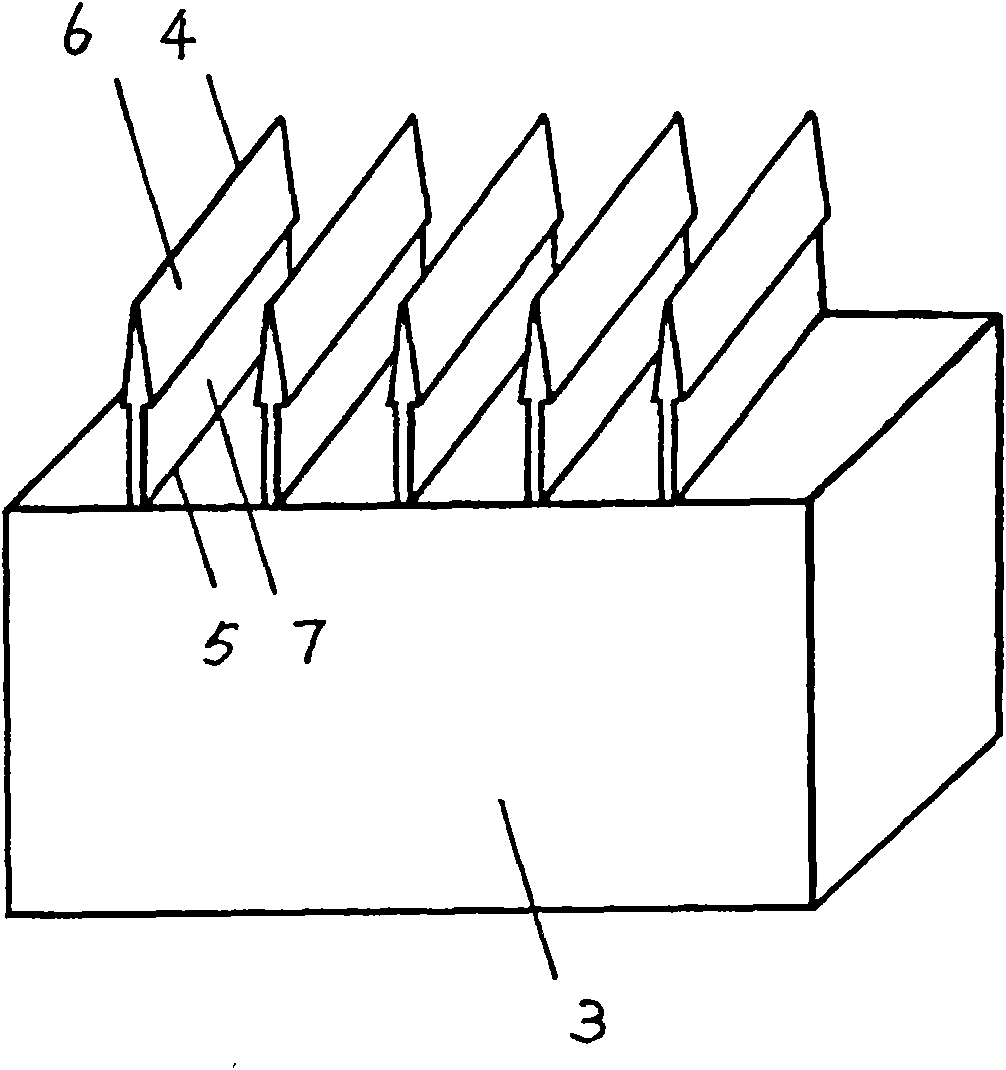

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the dental floss slicing membrane split forming device of the invention comprises a slicing membrane split mechanism, a molding die 2 and a frame 1 .

[0018] The slice membrane splitting mechanism is formed by a base 3 and a membrane splitting blade 4 .

[0019] The upper end surface of the base 3 is evenly distributed with longitudinal membrane splitting grooves 5 .

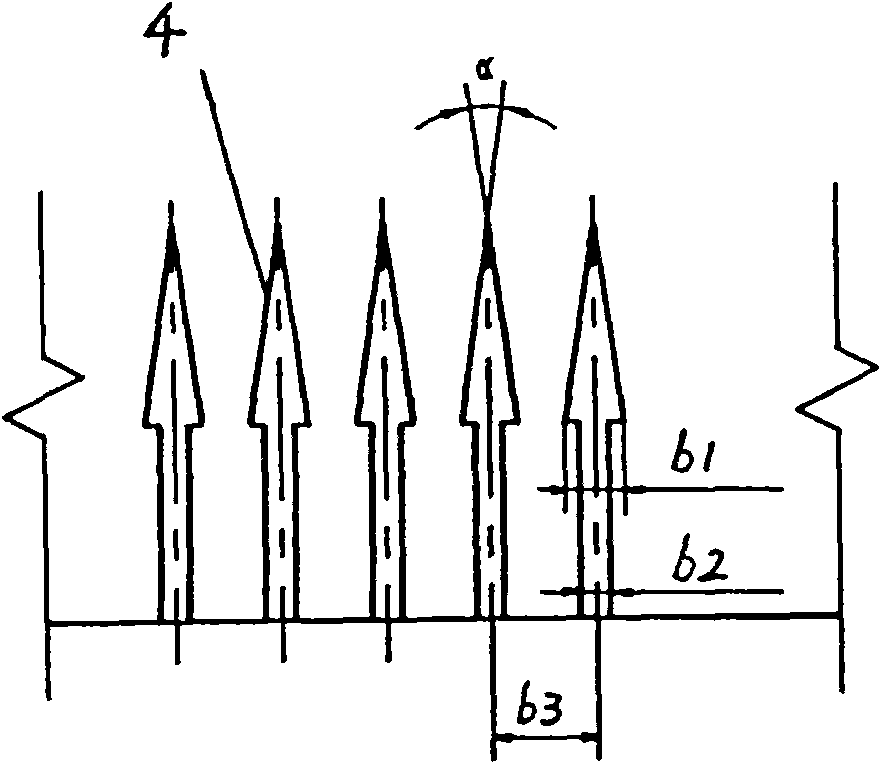

[0020] The membrane splitting blade 4 is in the shape of an arrow, and the membrane splitting blade 4 is composed of a cutter head 6 and a knife handle 7, and the tip angle α of the cutter head 6 of the membrane splitting blade 4 is 5°-18° °, the width b of the lower end of the cutter head 6 of the membrane splitting blade 4 1 Be 3~5mm, the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com