Braking mechanism of automobile steering driving front axle

A technology of braking mechanism and front axle, applied in the direction of braking components, brakes, brake transmission devices, etc., can solve problems such as poor braking effect and inability to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

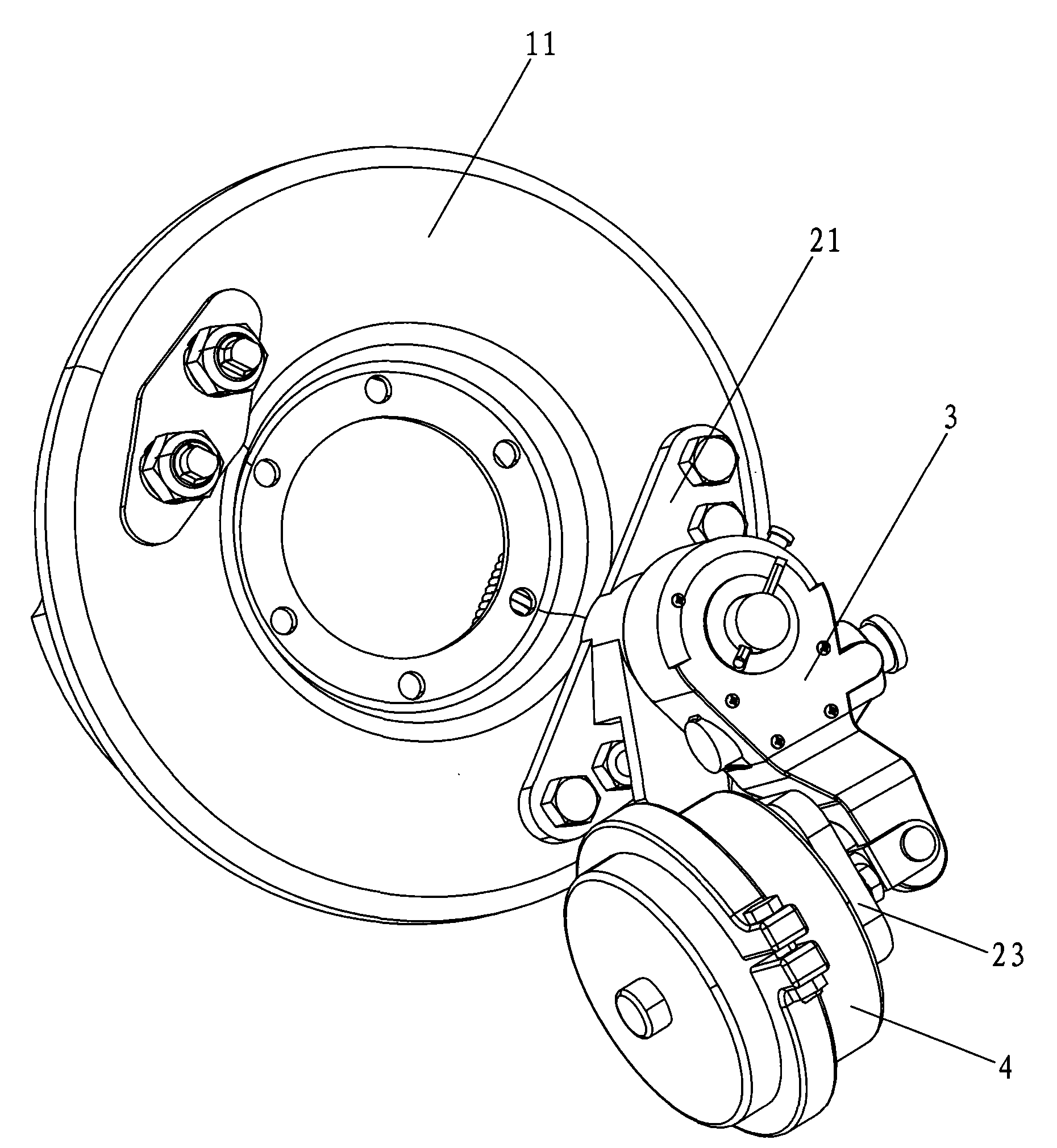

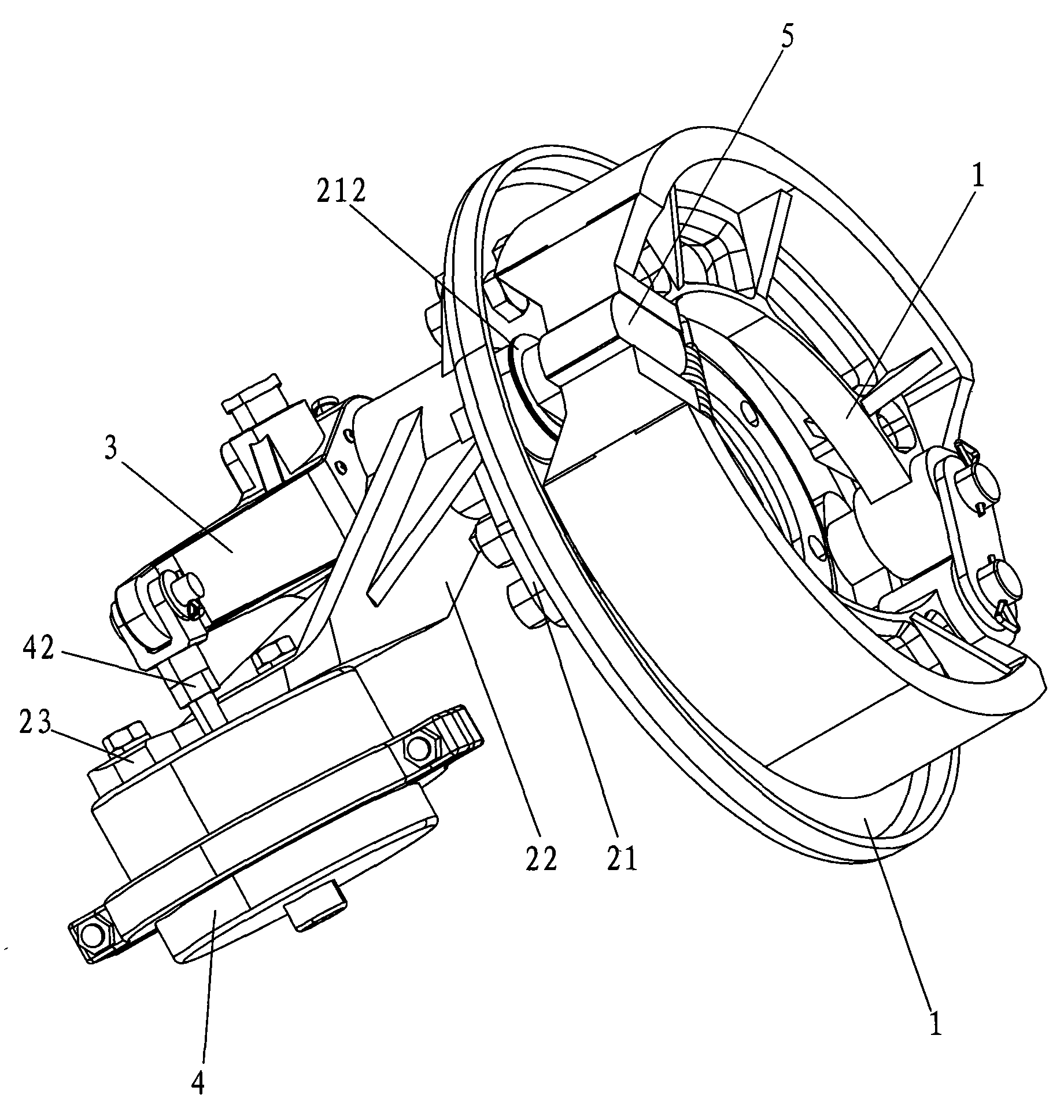

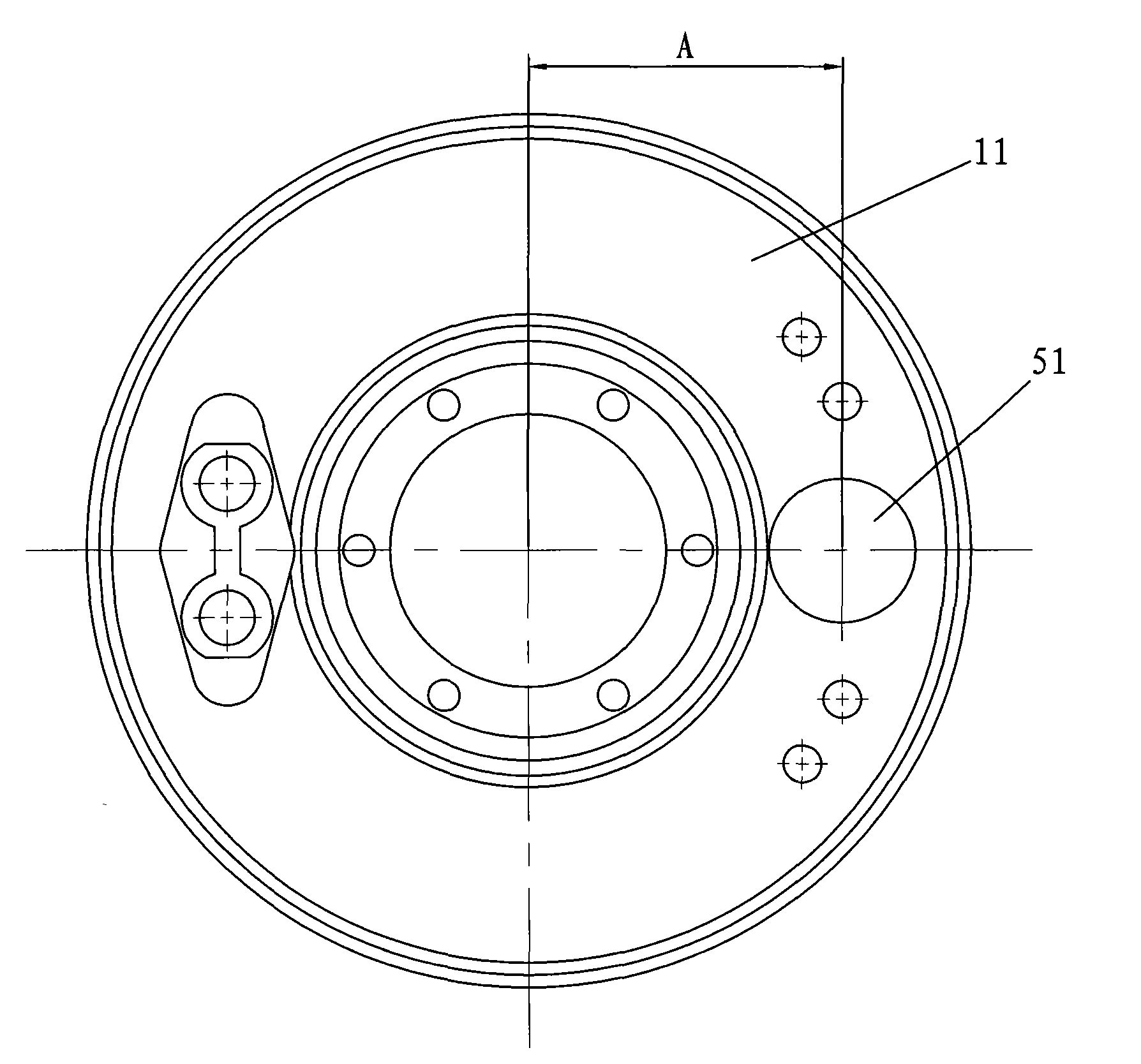

[0016] Automobile of the present invention turns to drive front axle braking mechanism, as Figure 1-5 As shown, it includes a brake 1, an air brake seat 2, a brake adjustment arm 3, an air chamber 4 and a camshaft 5. The brake 1 has a brake base plate 11, and the air brake seat 2 includes a fixed plate 21, a connecting plate 22 and an air brake seat that are sequentially connected integrally. The chamber fixing seat 23, the fixing plate 21 is flatly fixed on the brake base plate 11, and the fixing plate 21 is provided with a through hole 211 for the camshaft 5 to pass through, and the hole of the through hole 211 is formed along the extension to match the camshaft 5 The shaft sleeve 212, the brake base plate 11 is provided with a camshaft installation hole 51 for the shaft sleeve 212 to pass through, the camshaft 5 is installed in the shaft sleeve 212, and the air chamber 4 is installed through the air chamber on the air chamber fixing seat The hole 41 is installed on the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com