Wide roller kiln for burnt porcelain brick

A roller kiln and porcelain brick technology, applied in the field of roller kiln, can solve the problem that the temperature difference of the cross section of the roller kiln cannot be effectively controlled and eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

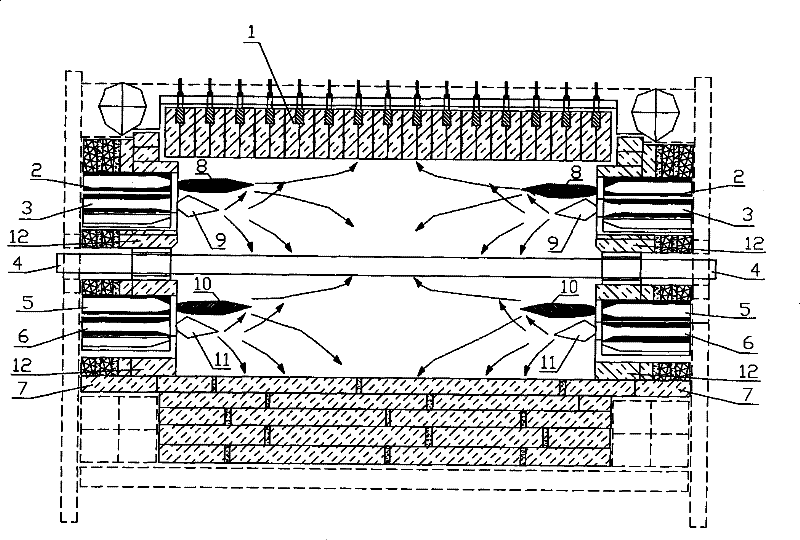

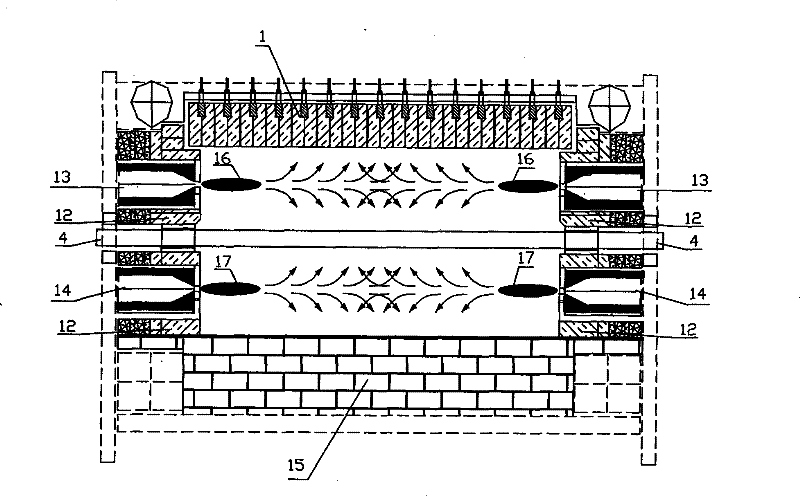

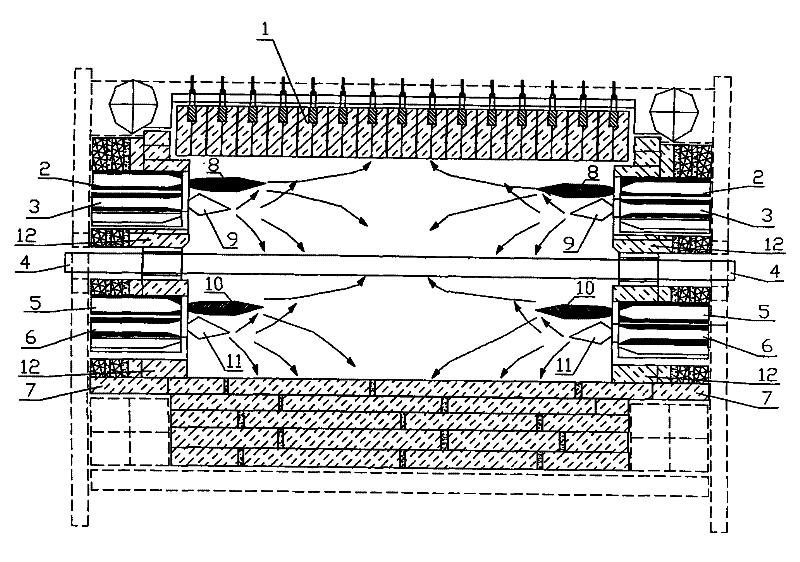

[0034] exist figure 1Among them, the two sides of the wide-body roller kiln of the present invention are provided with a remote burner with a gradient of the reducer and a short-range burner with a gradient of the expander. More specifically: with the roller bar 4 as the boundary, there are The remote burner 2 on the roll of the diverter tube gradient, the short distance burner 3 on the roll of the expander tube gradient, the remote burner 5 of the roll down roll of the expander tube gradient tube and the short distance burner 6 of the roll below the expander tube gradient tube. The remote combustion system controls the output pressure and flow of the remote burner, and the short-range combustion system controls the output pressure and flow of the short-range burner. The kiln burner includes a spray gun and a burner brick. The kiln body burner sprays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com