Method for controlling motion mechanisms used on laser cutting equipment

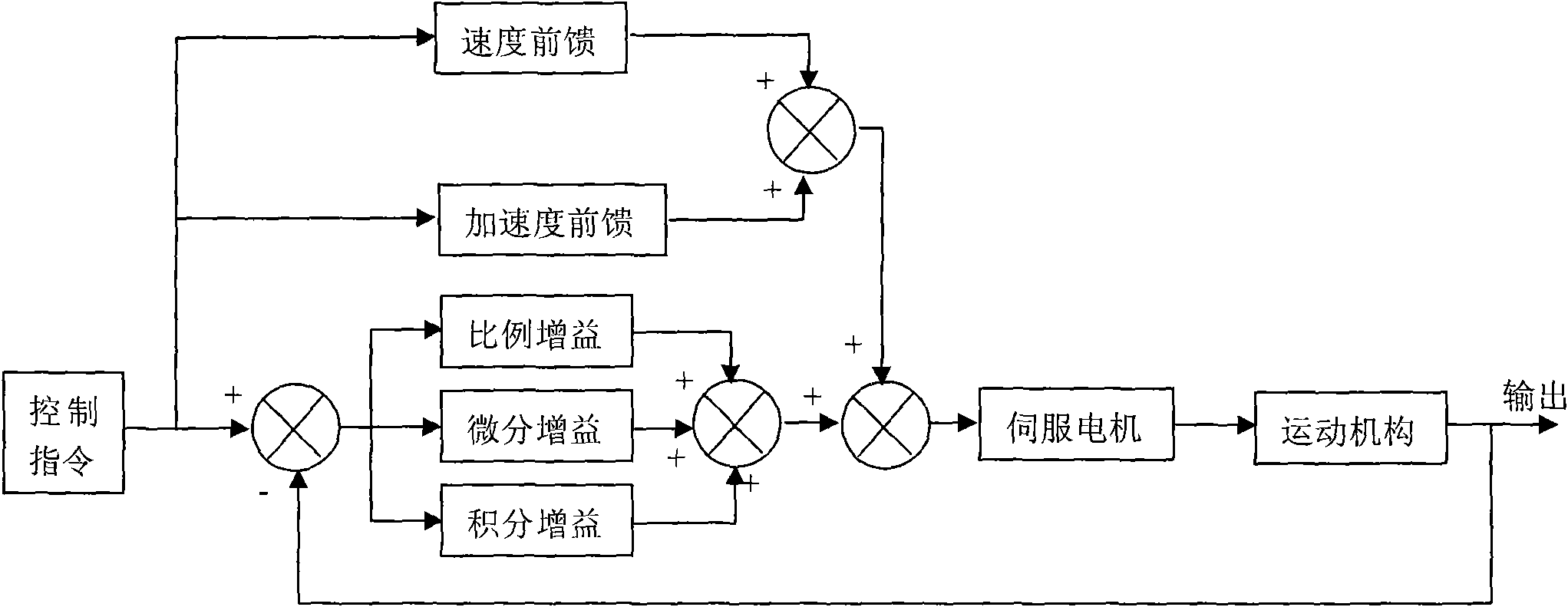

A motion mechanism and laser cutting technology, applied in laser welding equipment, electric controllers, controllers with specific characteristics, etc., can solve problems such as vibration or howling, motion mechanism deviation, and reduce system indicators to achieve a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

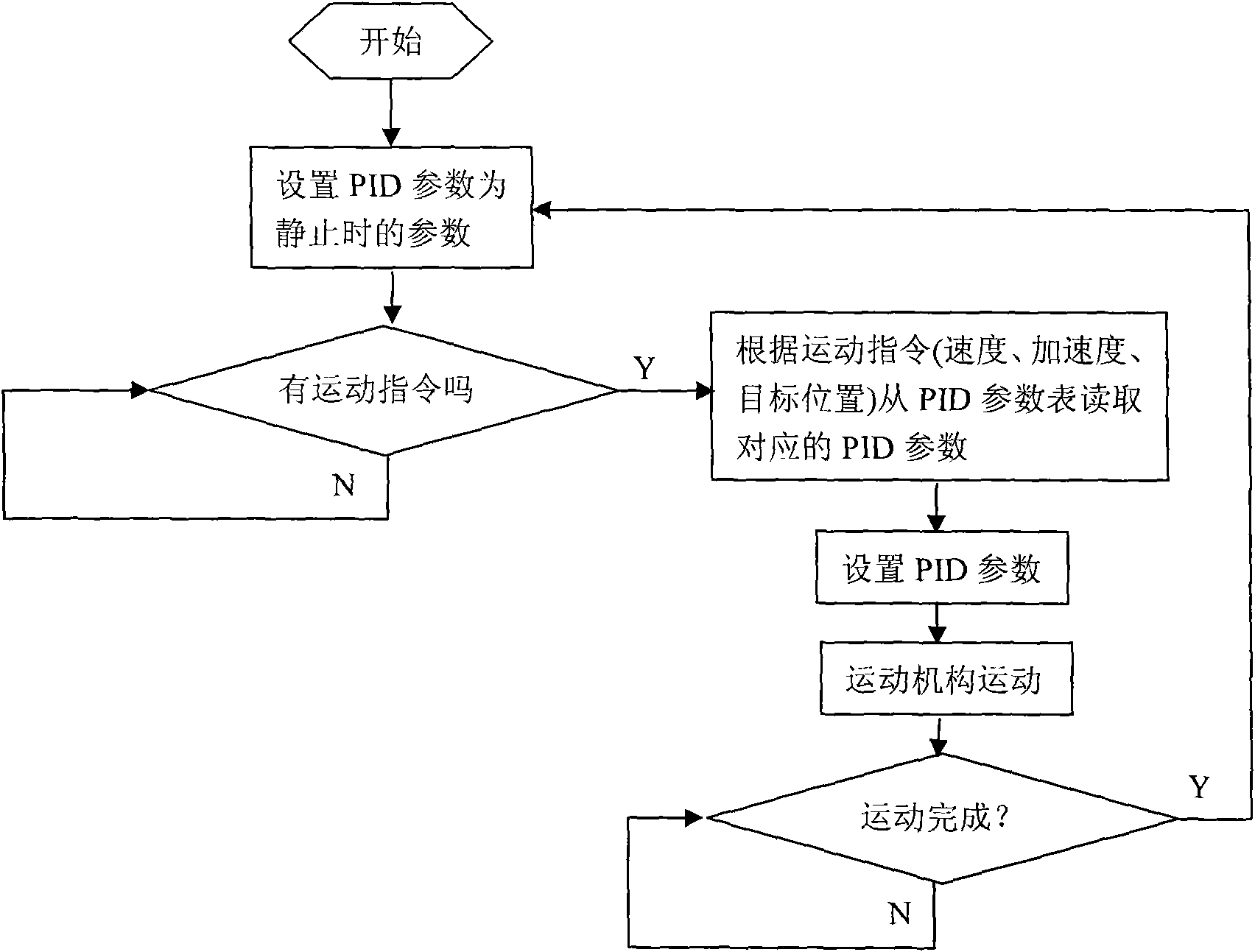

[0019] Such as figure 2 As shown, a control method for a kinematic mechanism on a laser cutting device controls the movement of a kinematic mechanism on a laser cutting device through PID parameters input to a PID controller, including the following steps:

[0020] (1) PID parameters are set to static PID parameters;

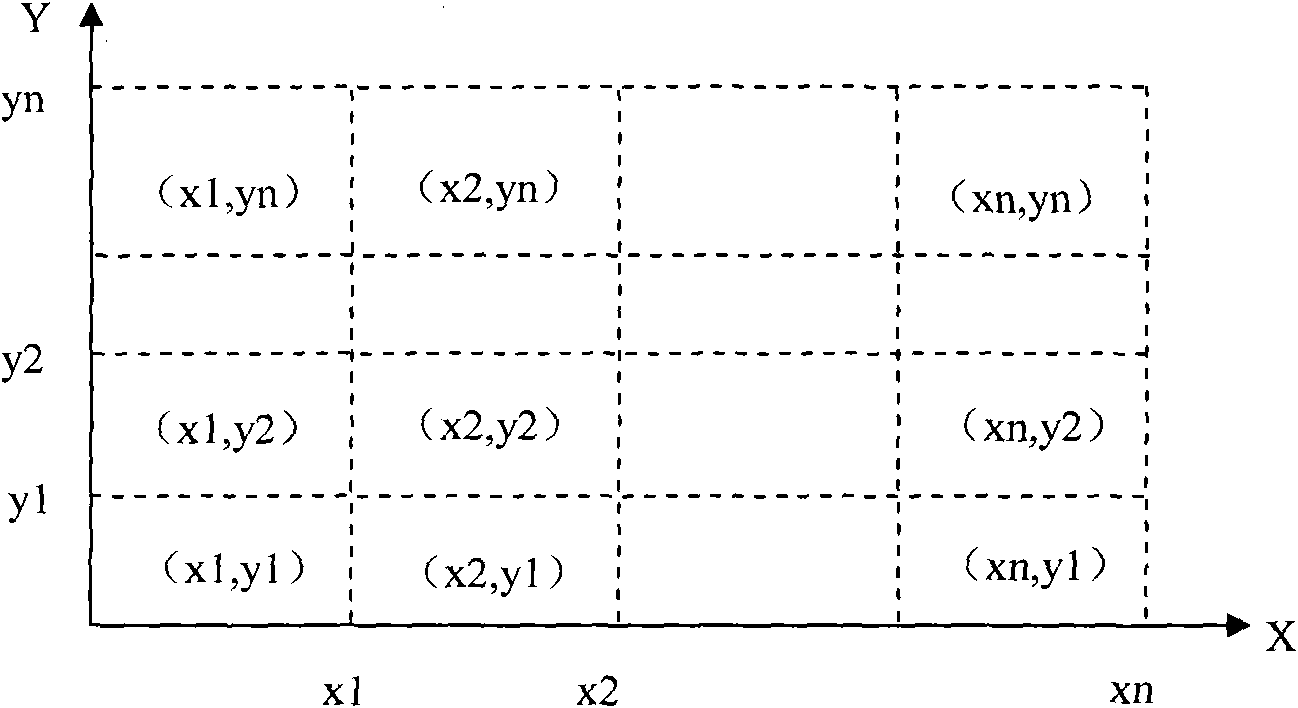

[0021] (2) Judging whether there is a motion command, if there is, the PID parameter is used as the motion PID parameter to control the motion of the motion mechanism, the motion PID parameter is selected from the motion PID parameter database, and then its area is selected according to the location of the motion mechanism Motion PID parameters, the motion PID parameter database stores the regional motion PID parameters of all areas given according to the different plane position areas where the motion mechanism is located; otherwise, continue to judge whether there is a motion command; the plane position area where the motion mechanism is located division as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com