Method and fixture for reverting position of horizontal sliding table

A technology of horizontal sliding table and sliding table, which is applied in the direction of measuring device, testing of machine/structural components, vibration test, etc. The effect of error, precise vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

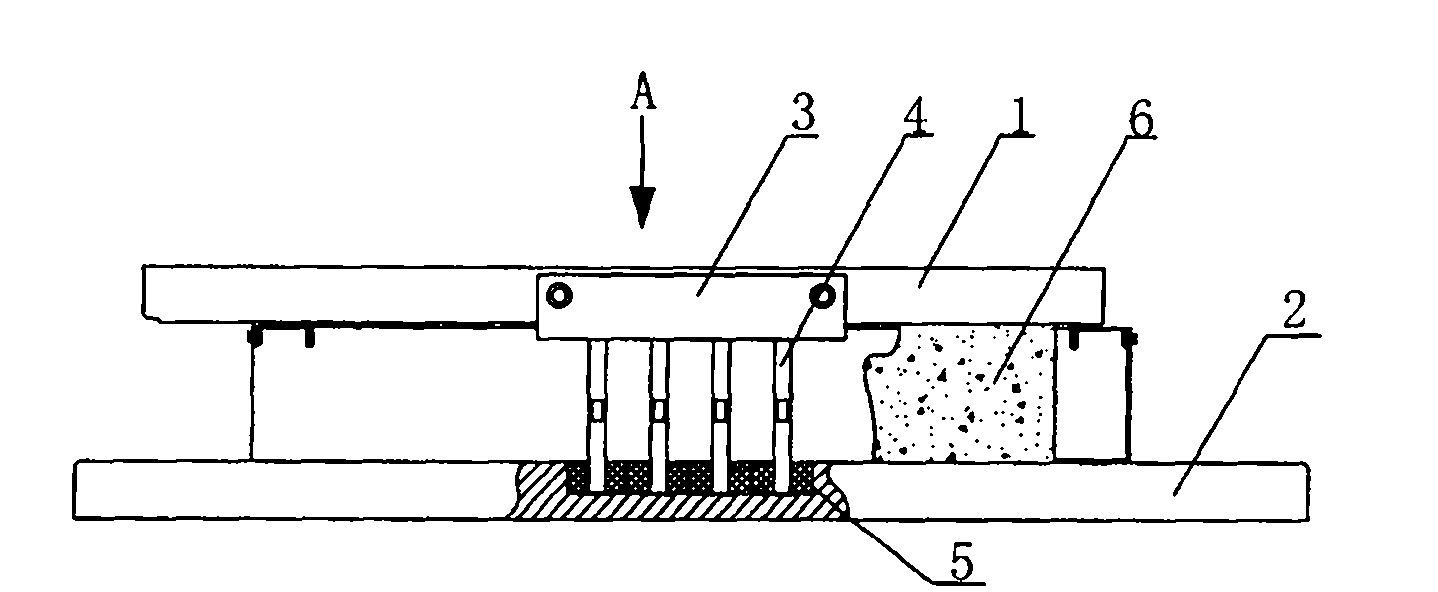

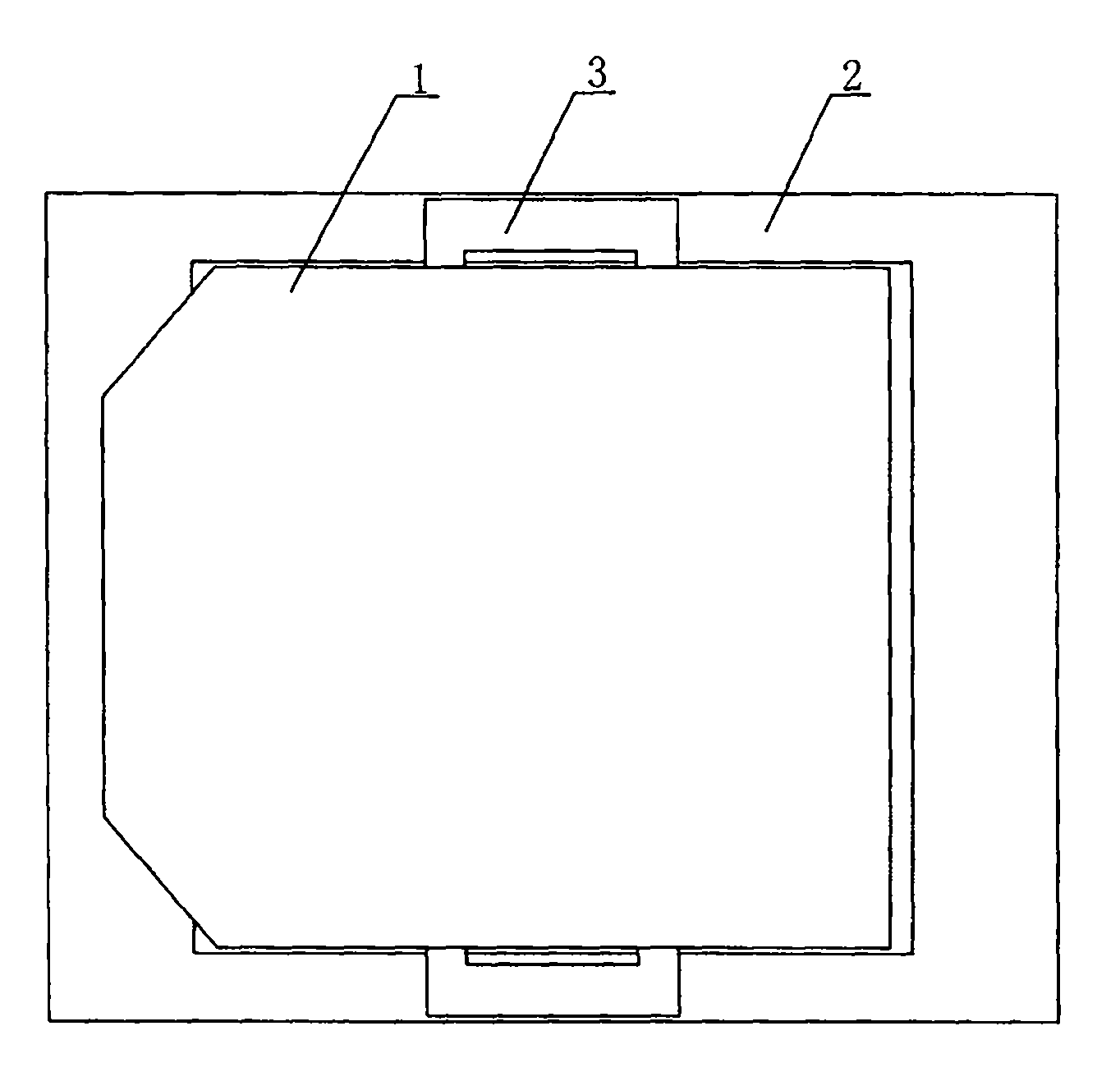

[0030] Example 1 as figure 1 and 2 , the return positioning device of the horizontal sliding table is an oil film horizontal sliding table structure, which includes a worktable 1 and a worktable support 2, and the worktable support supports the worktable 1 through the granite platform 6 oil film arranged on it. The left end of the worktable is connected to the vibration generator through a connector, and an elastic return positioning mechanism is fixedly connected between the worktable and the support body of the worktable. The elastic return positioning mechanism is a rigid shaft connector with rubber elastic bodies at both ends. The rubber elastic body 5 Fixed at both ends of the rigid shaft 4, fixed grooves 3 are provided on the corresponding sides of the worktable, the rubber elastic bodies at one end of the four rigid shaft connectors are fixed side by side in the rigid fixed groove 3, and the other end of the rigid shaft 4 is rubber elastic The body 5 is fixedly arrange...

Embodiment 2

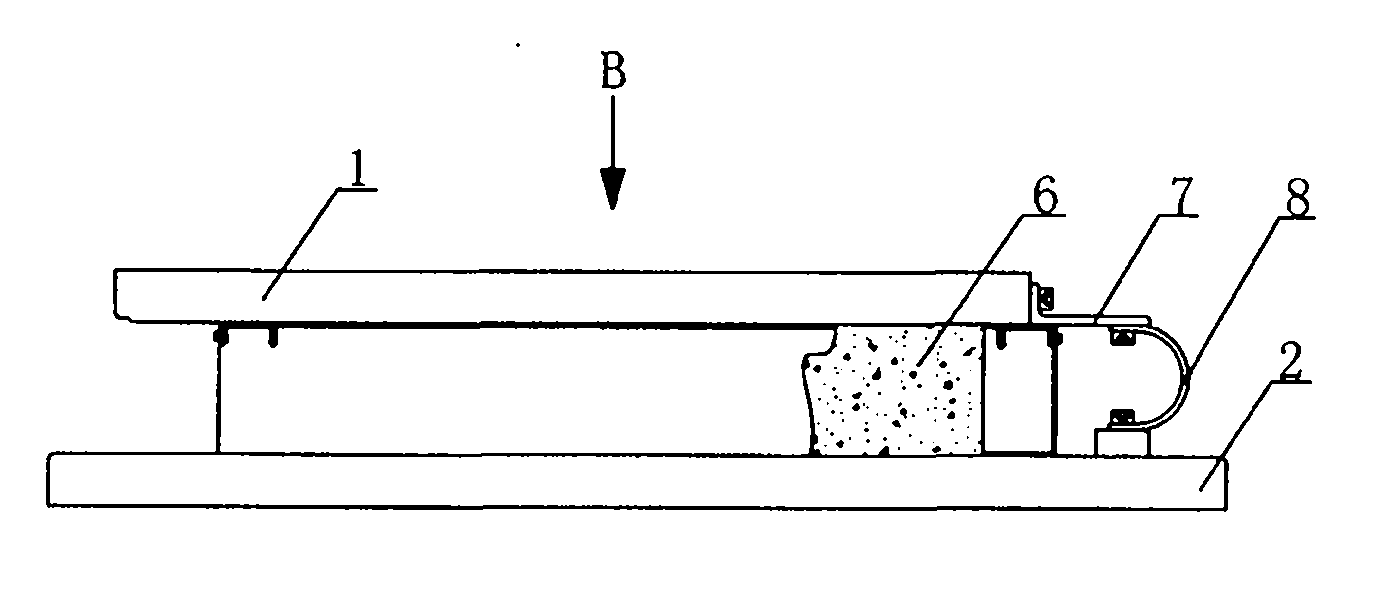

[0032] Example 2 as image 3 and 4 , the return positioning device of the horizontal sliding table is an oil film horizontal sliding table structure, including a worktable 1 and a worktable support 2, and the worktable support supports the worktable 1 through the granite platform 6 oil film arranged on it. The left end of the worktable is connected to the vibration generator through a connector, and a U-shaped spring 8 is fixedly connected between the side of the worktable corresponding to the connector and the support body of the worktable. The U-shaped spring 8 is composed of two or more than two pieces of U-shaped shrapnel It is formed by superimposing, one end of which is fixed on the fixed pressing piece 7 at the end of the worktable, and the other end is fixedly arranged on the upper end surface of the support body of the worktable by bolts.

[0033]When the device is used for horizontal vibration test, the working surface of the horizontal sliding table is reciprocatin...

Embodiment 4

[0035] Example 4 as Figure 7 , the return positioning device of the horizontal slide table is an air spring slide table structure, including a work table 1, an air spring 9 and a work table support body 2, the work table is arranged on symmetrically distributed air springs, and the work table Lift it up to make the worktable vibrate in the horizontal direction. The left end of the worktable is connected to the vibration generator through a connector 10, the rigid shaft connectors of the elastic body 5 are fixed at both ends of the fixed connection between the worktable 1 and the worktable support body 2, and the rubber elastic body 5 is fixed on the two ends of the rigid shaft 4, One end of the rigid shaft 4 is fixedly connected to the lower end surface of the worktable corresponding to the connector, and the other end is fixedly arranged on the support body of the worktable. One side of the worktable is provided with a fixed groove 3, and the rubber elastic bodies at one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com