Method for preparing Zr-doped beta-FeOOH anion-exchange arsenic removal adsorbent

An exchange-type, adsorbent technology, applied in the field of preparation of arsenic removal adsorbent, can solve the problems of high operating cost, poor removal effect of trivalent arsenic, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical characteristics and advantages of the present invention can be seen through the embodiments and application examples given below.

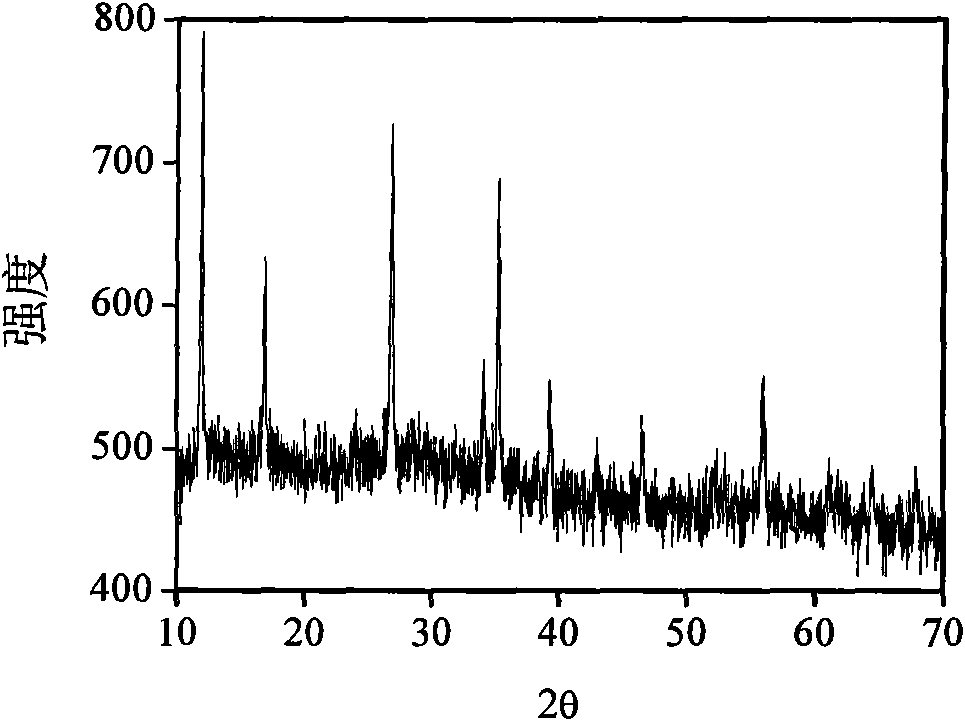

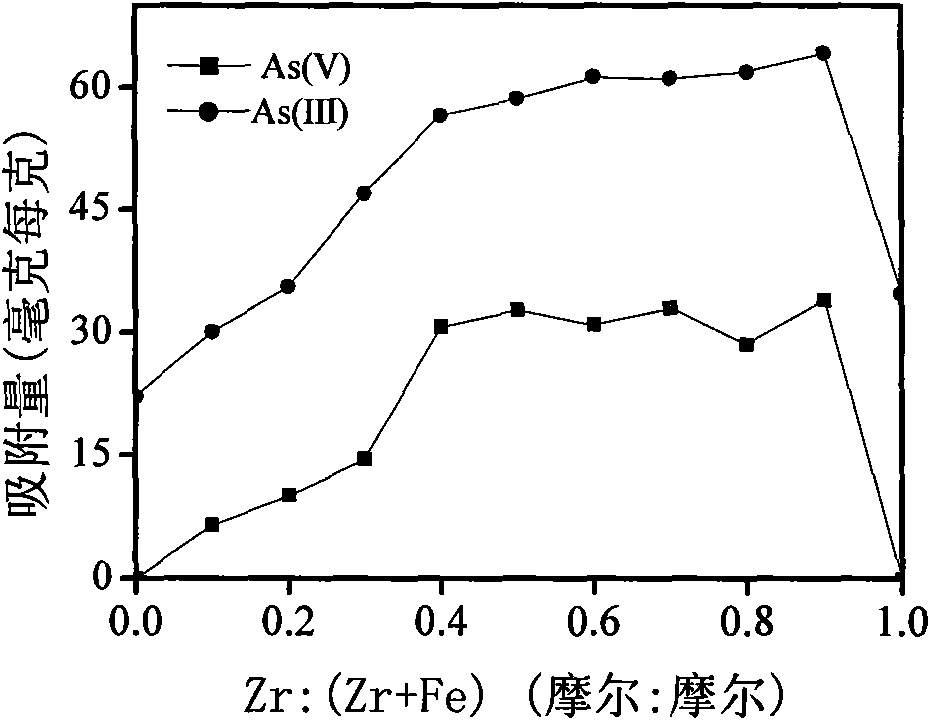

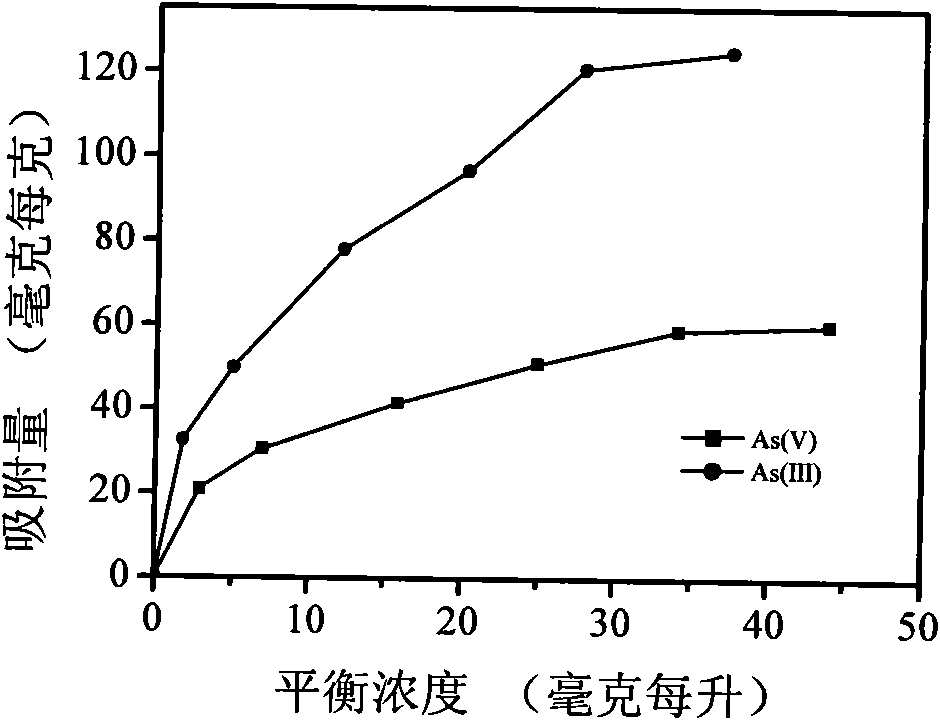

[0012] 1. Structural characteristics and arsenic removal performance of Zr-doped β-FeOOH anion-exchange adsorbent

[0013] The preparation of the adsorbent adopts the liquid phase homogeneous precipitation method, and a certain amount of FeCl 3 ·6H 2 O, ZrOCl 2 ·8H 2 O and CO(NH 2 ) 2 Prepare a mixed solution with a certain ratio and a certain concentration, in which FeCl 3 ·6H 2 O and ZrOCl 2 ·8H 2 The mass ratio of O is 16:0-14; FeCl 3 ·6H 2 O and ZrOCl 2 ·8H 2 The total concentration of O is 0.2mol L -1 ;CO(NH 2 ) 2 with (FeCl 3 ·6H 2 O+ZrOCl 2 ·8H 2 The mass ratio of O) is 15:9; then the mixed solution is put into an oven at 100° C. for 4 hours, and the reaction generates a brown precipitate, which is washed with deionized water, and then dried at 40° C. for 48 hours to obtain Zr-doped β-FeOOH anion-exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com