Method and device for treating SO2-containing waste gas

A treatment method and exhaust gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of activated carbon adsorption materials loss, adsorption capacity needs to be improved, etc., to achieve efficient recovery and reuse, and improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the adsorption material is as follows: MOF-5 is used as the matrix, and the specific surface area is 1655 m 2 / g, the pore volume is 1.13 cm 3 / g. In the presence of nitrogen, the carbonization time was 6 hours at 1000° C. to obtain a carbonized material. The carbonized material was placed in a sodium sulfite solution, impregnated with an equal volume, and dried under nitrogen at 120°C to obtain SO 2 Adsorption material, sodium sulfite loading ratio is 5%. After testing, the specific surface area of the prepared material is 2426 m 2 / g, the pore volume is 3.27 cm 3 / g.

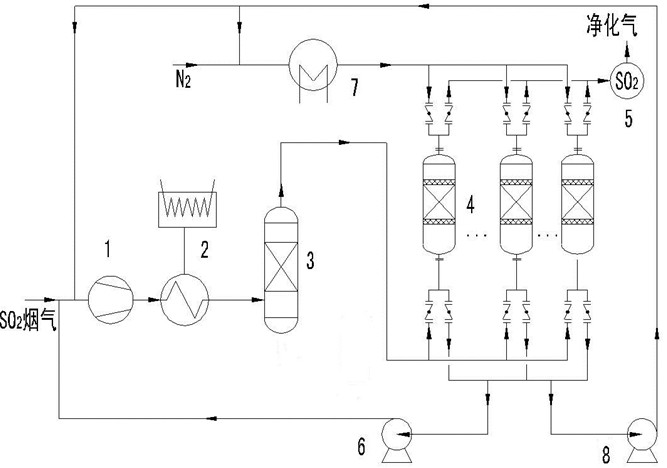

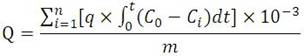

[0028] According to attached figure 1 The processing flow, first will contain SO 2 The flue gas is compressed and condensed, the gauge pressure is controlled at 0.5MPaG, and the temperature is 5°C. The compression condensation enters the adsorption unit after passing through the buffer tank, and the adsorption unit is filled with the above-mentioned carbonized metal or...

Embodiment 2

[0031] Implementation method is the same as embodiment 1, and difference is the SO that adopts 2 The loading of sodium sulfite in the adsorbent material was 1%. After one month of operation, the adsorption capacity of the adsorbent can be stabilized at more than 85% of the initial adsorption capacity, and SO can be recovered under the same number of cycles 2 About 0.92 tons.

Embodiment 3

[0033] Implementation method is the same as embodiment 1, and difference is the SO that adopts 2 The loading of sodium sulfite in the adsorbent material was 7%. After one month of operation, the adsorption capacity of the adsorbent can be stabilized at more than 85% of the initial adsorption capacity, and SO can be recovered under the same number of cycles 2 About 1.12 tons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com