Industrial engineering head for computer cutting and proofing

An industrial and engineering technology, which is applied in the field of tool heads, can solve the problem that the drawing pen assembly, the pressure wheel assembly and the vibrating knife assembly cannot be disassembled and interchanged, and achieve the effect of humanized loading and unloading operation, convenient disassembly and interchange, and simple and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

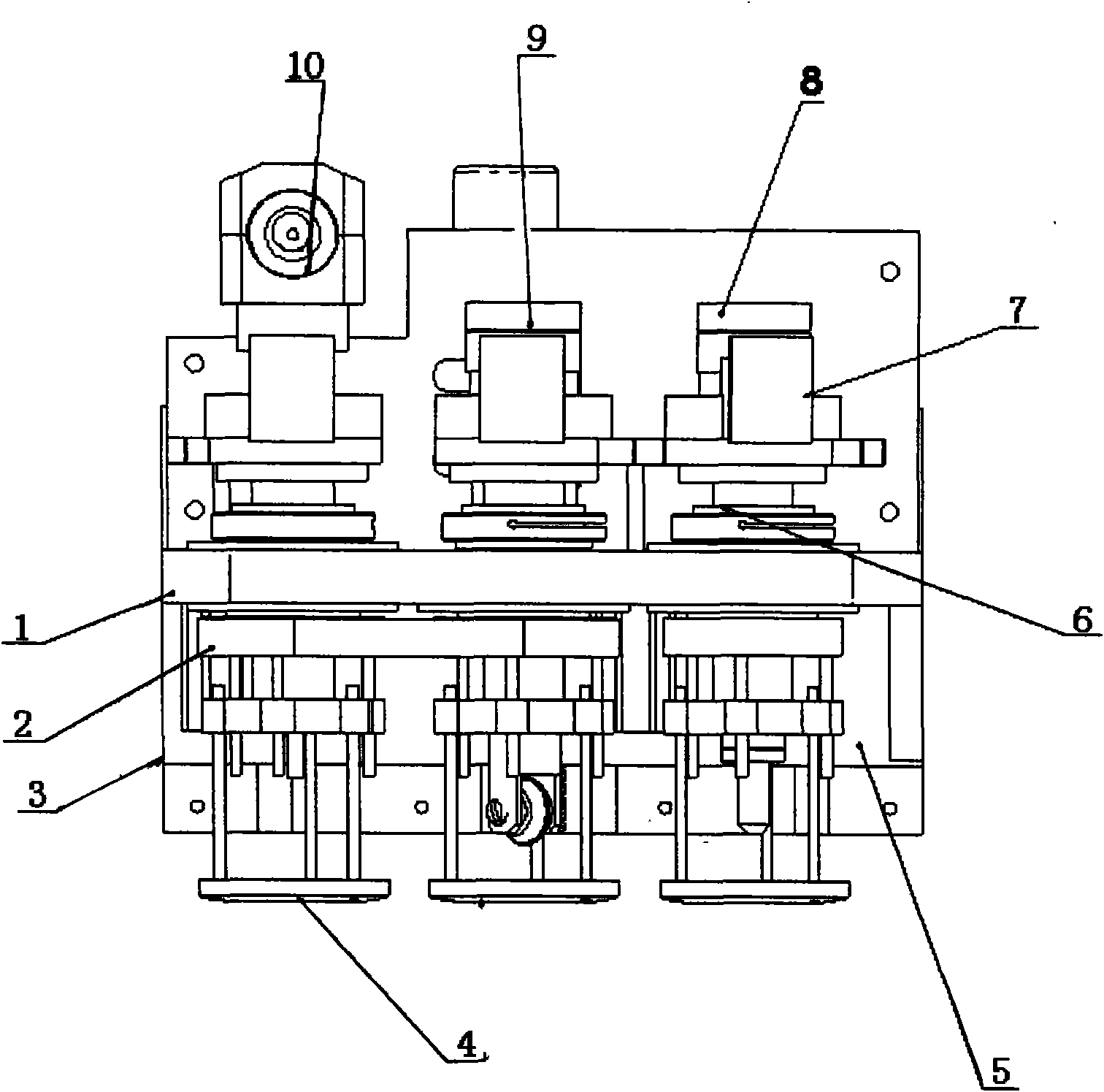

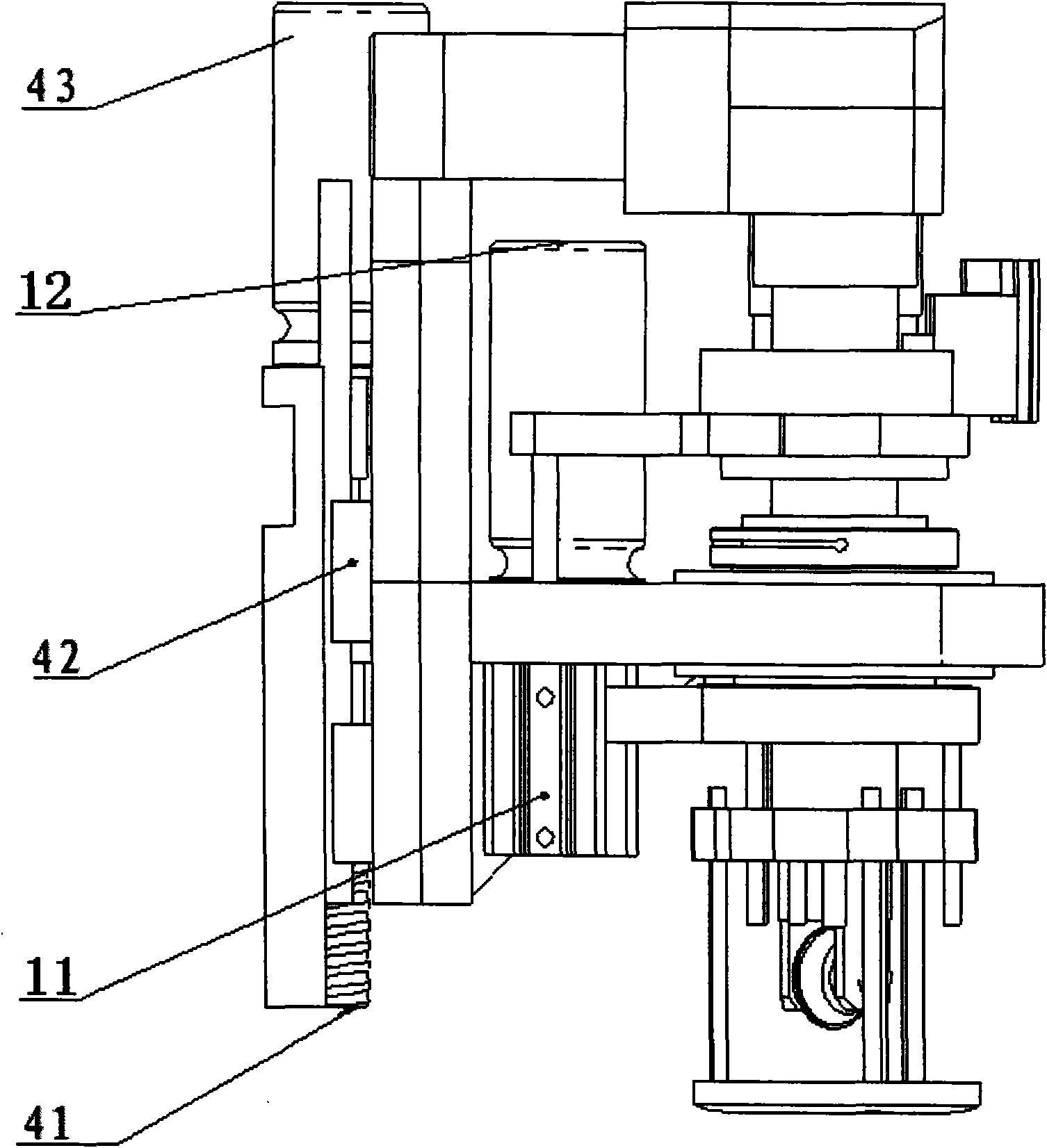

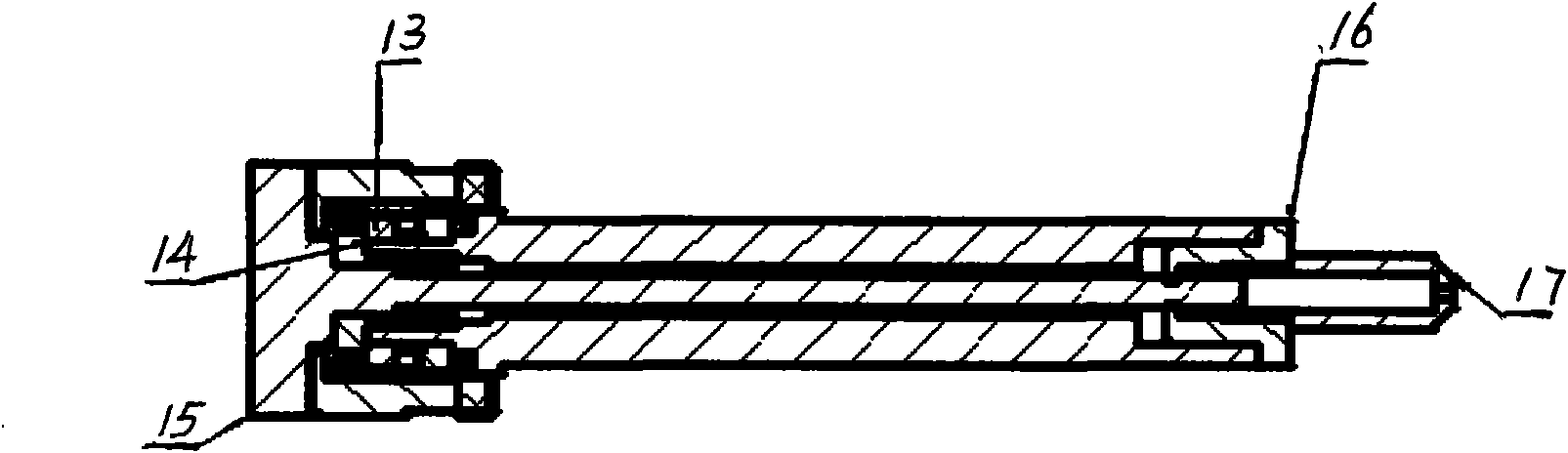

[0017] Such as Figure 1A and Figure 1B As shown, it is a structural schematic diagram of an industrial engineering head for computer cutting and proofing. The industrial engineering head for computer cutting and proofing includes a main mounting plate 1, a synchronous wheel assembly 2, a support plate 3, a press Foot assembly 4, rear mounting plate 5, rotating sleeve assembly 6, tool head locking assembly 7, pen assembly 8, pressure wheel assembly 9, vibrating knife assembly 10, air cylinder assembly 11 and servo motor assembly 12.

[0018] The main mounting plate 1 is vertically installed on the rear mounting plate 5 through the support plates 3 on both sides, and the detachable drawing pen assembly 8, pressing pen assembly 8, and pressing pen are vertically installed on the main mounting plate 1 by rotating the sleeve assembly 6 and the tool head locking assembly 7. The wheel assembly 9 and the vibrating knife assembly 10, the drawing pen assembly 8, the pressure wheel ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com