Tilting and oscillating car unloader

A car unloading machine, swinging technology, applied in the direction of loading/unloading, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, pollution, etc., to solve environmental protection problems, solve unloading problems, and facilitate environmental protection problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

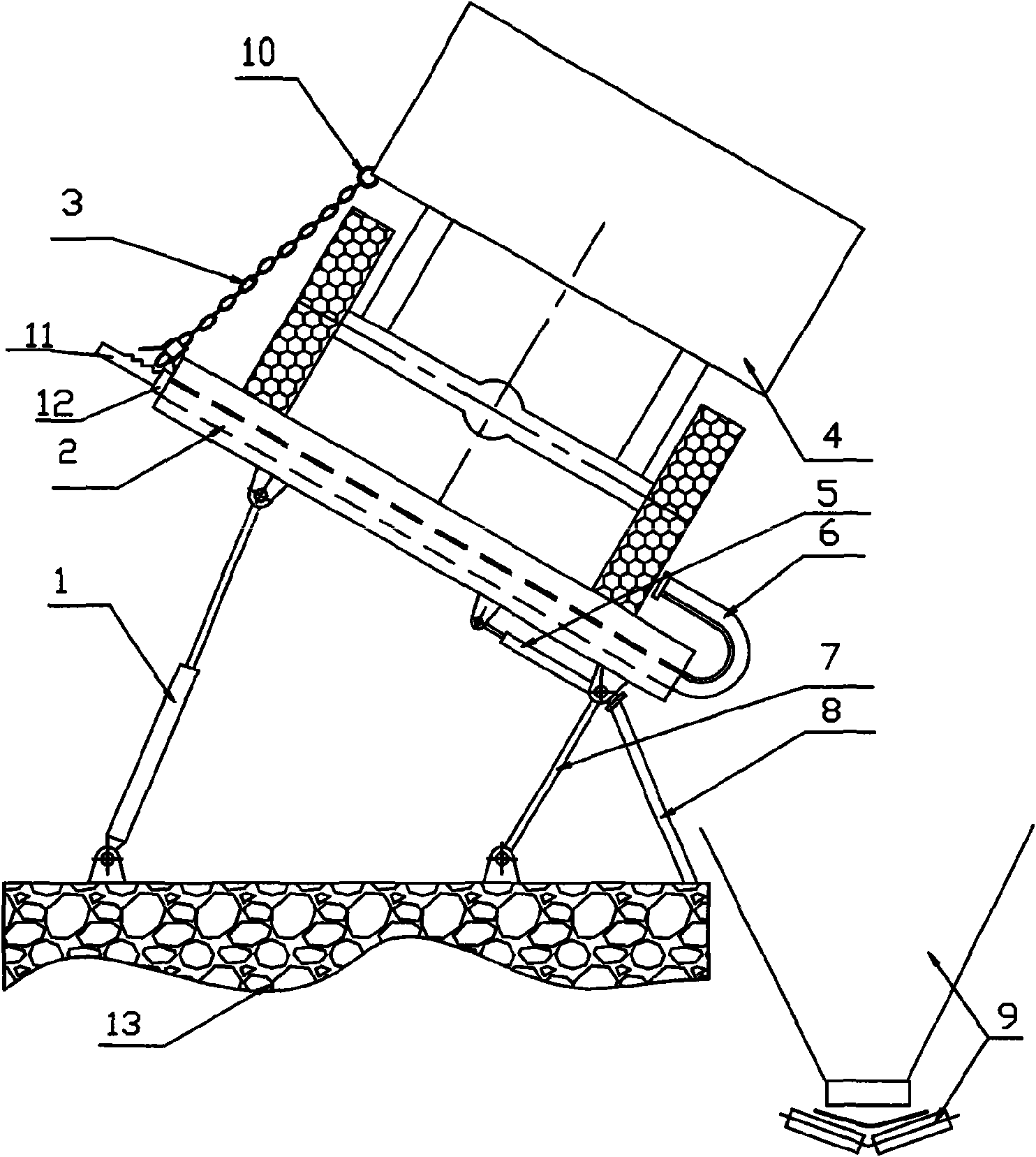

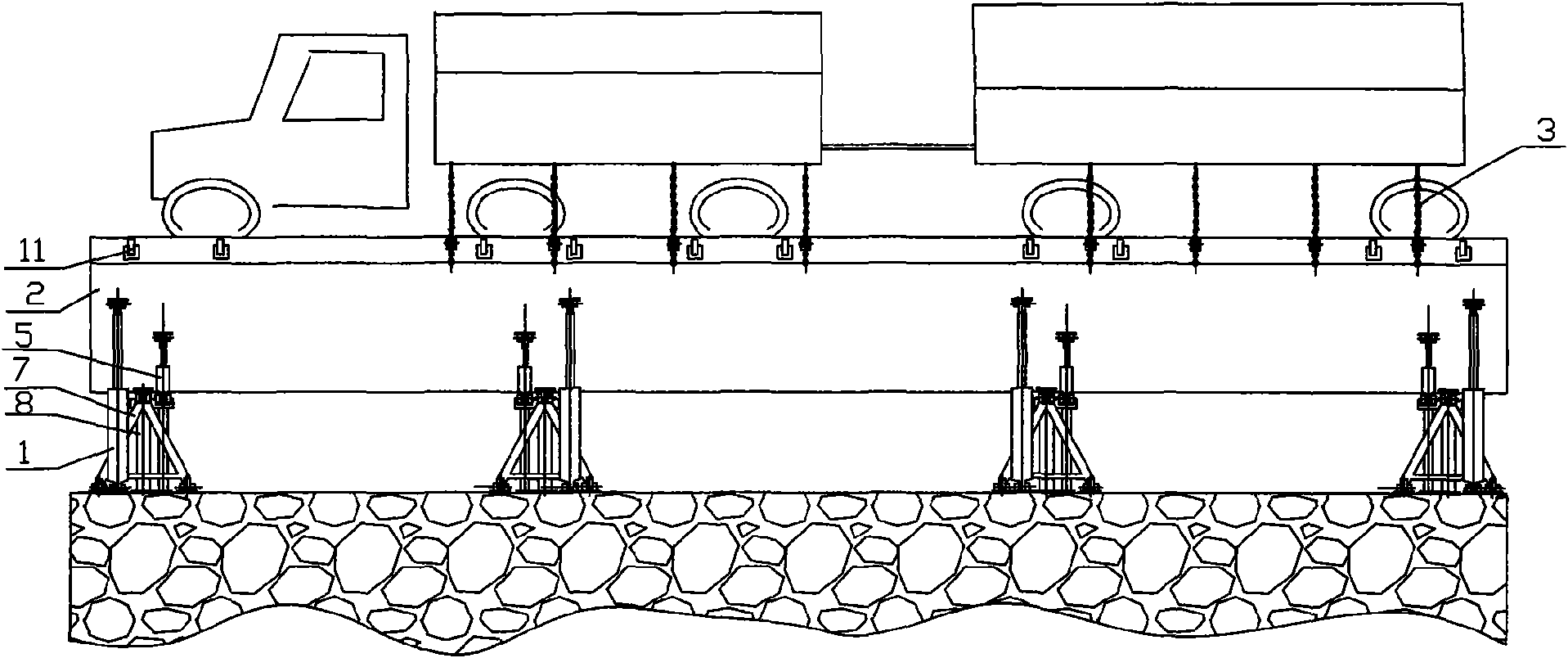

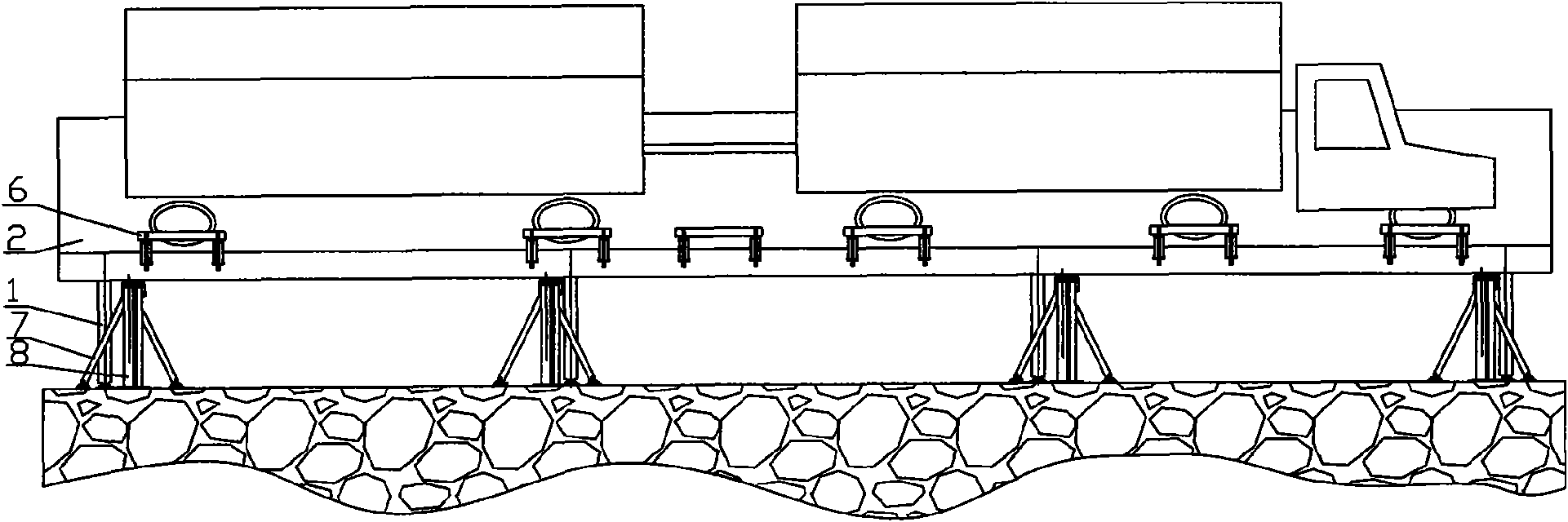

[0012] Refer to attached figure 1 , 2 , 3, the present invention comprises unloading platform 2, and unloading platform 2 can park whole vehicle, is provided with four sets of main pushing hydraulic cylinders 1 side by side along the vehicle length direction at the bottom of one side of unloading platform 2, the hydraulic rod of main pushing hydraulic cylinder 1 and The unloading platform 2 is hingedly connected. A row of chains 3 with adjustable length are evenly arranged on the edge of the side of the unloading platform 2 provided with the main push hydraulic cylinder along the length direction of the vehicle. Locking hooks 10 are connected to the ends of the chains 3. On the edge of the other side of the unloading platform 2 opposite to the side where the chain 3 is installed, a row of blocking frames 6 is evenly arranged along the vehicle length direction. To the side that chain 3 is housed, and can move left and right, locking device 12 is housed at its end. On the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com