Rapid connecting structure of pipe fitting

A technology for quick connection and pipe fittings, which is applied in the direction of connecting components, rods, motor vehicles, etc. It can solve the problems that the two pipe fittings cannot be quickly locked and disassembled, and the assembly and disassembly are troublesome. It has good application prospects and simple structure. , easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

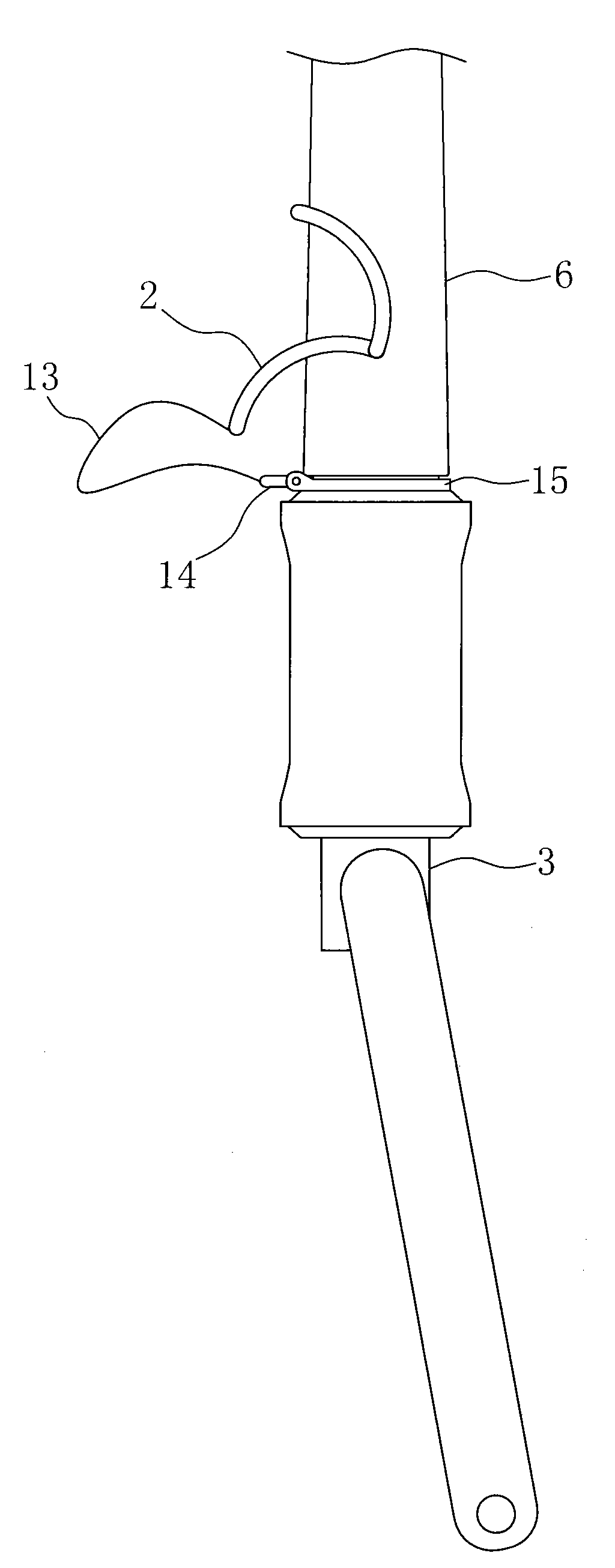

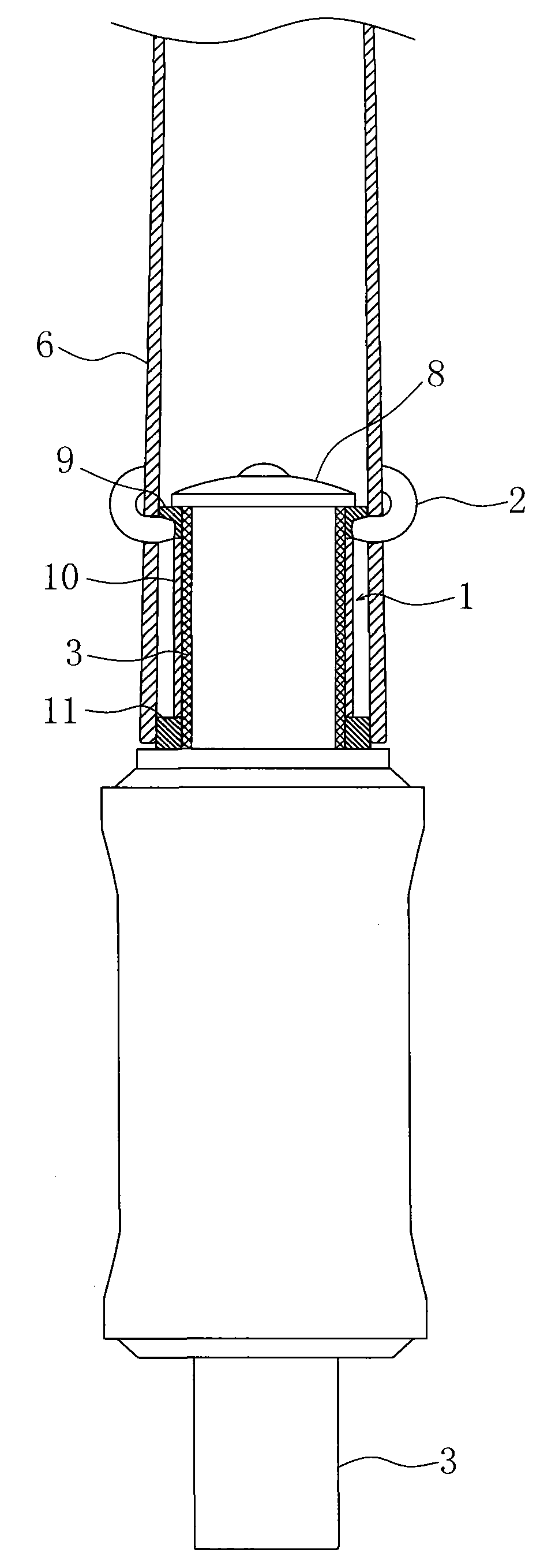

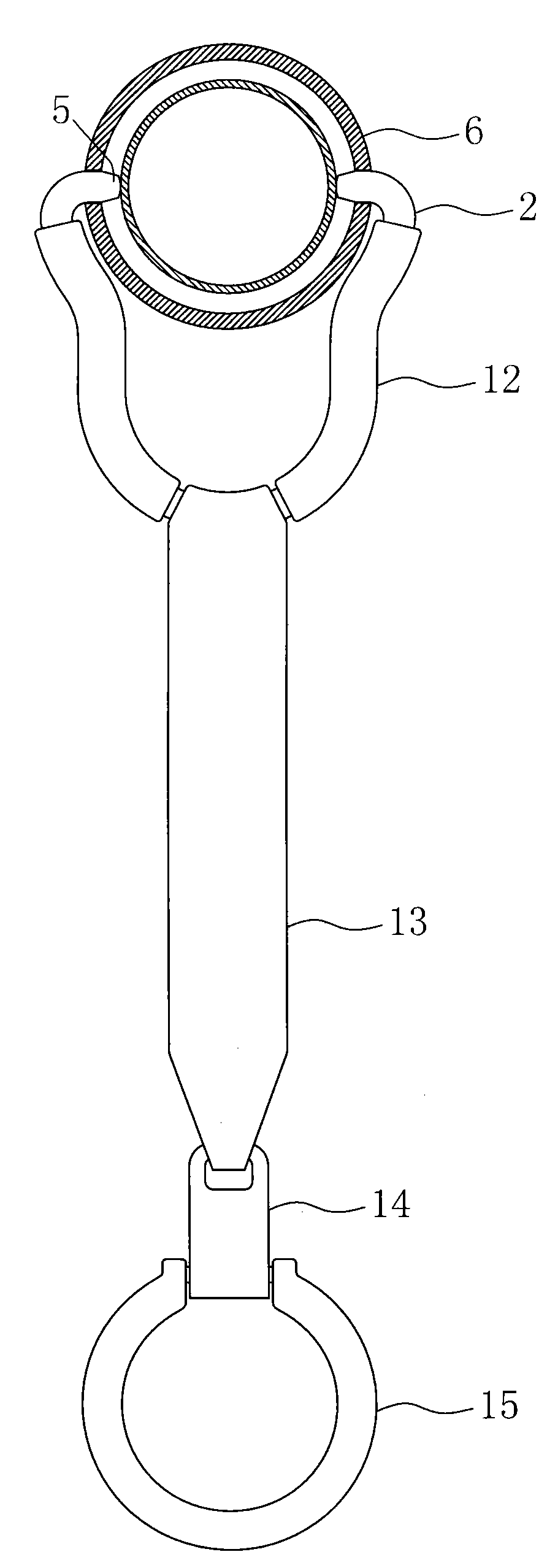

[0040] See attached Figure 1-10 As shown, a quick connection structure of pipe fittings, the outer pipe fittings and the inner pipe fittings are plugged and positioned through the connecting parts. The connecting parts include a sleeve 1 and an annular spring part 2 with one end open, and the open end of the spring part 2 faces inward. Bending to form a pair of plugs 5; the sleeve 1 is sleeved and fixed on the upper end of the inner pipe 3, and both the inner pipe 3 and the sleeve 1 are inserted into the inside of the outer pipe 6; a pair of through holes 4 are provided on the outer pipe 6 At least one groove is provided on the side wall of the casing 1 corresponding to the corresponding position of the through hole 4; the pair of plugs 5 of the spring member 2 are inserted into the pair of through holes 4 of the outer pipe member 6 , and the spring member 2 has at least two stable states when it rotates around the through hole 4 of the outer pipe member, forming two working ...

Embodiment 2

[0048] See attached Figure 11-12 As shown, a quick connection structure for pipe fittings, the outer pipe fittings and the inner pipe fittings are connected and positioned through the connecting piece. For the plug 5; a pair of through holes 4 are provided on the outer pipe member 6, and two openings are provided at corresponding positions corresponding to the through holes 4 on the inner pipe member 3 plugged into the outer pipe member; one of the spring members 2 The pair of plugs 5 are inserted into a pair of through holes 4 of the outer pipe member 6, and the spring member 2 has at least two stable states when rotating around the through hole 4 of the outer pipe member, forming two working positions:

[0049] (1) Locking position: the two plugs 5 of the spring member 2 pass through the through holes of the outer pipe member and are stuck in the opening of the inner pipe member; the distance between the two plugs of the spring member is less than the opening of the inner p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com