Method and device for monitoring multiple mirror arrays in an illumination system of a microlithographic projection exposure apparatus

A lighting system and microlithography technology, applied in the field of lighting systems, can solve the problems of large volume of beam deflection elements, affecting effective work, and large number of mirror elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] 1. Structure of projection exposure equipment

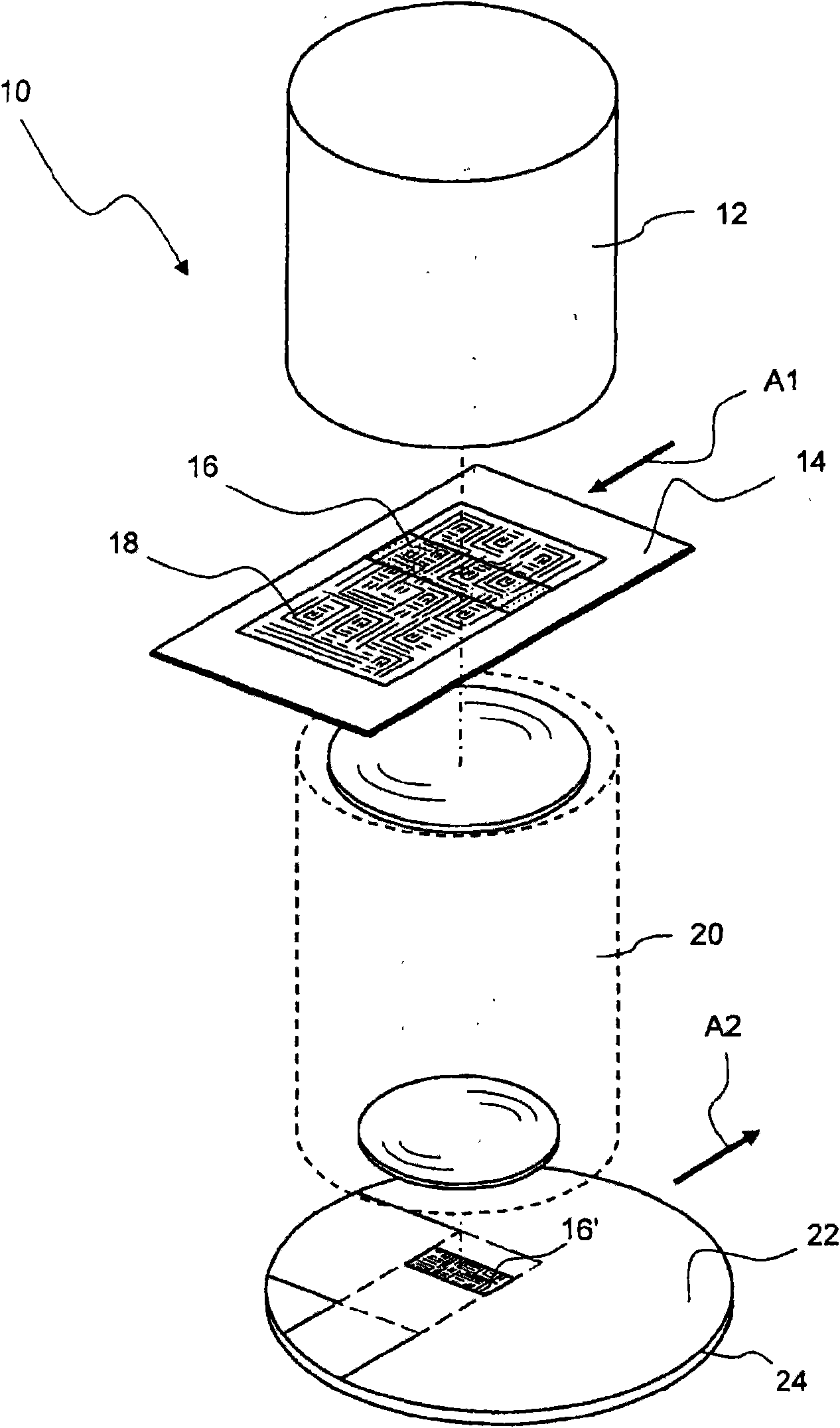

[0041] figure 1A perspective view of a projection exposure apparatus 10 is shown very schematically, which is suitable for the lithographic production of microstructured components. The projection exposure system 10 comprises an illumination system 12 which illuminates a narrow, in the exemplary embodiment shown, rectangular illumination field 16 on a mask 14 arranged in a so-called mask plane. The lighting system 12 contains light sources by means of which projected light can be generated. Commonly used light sources are, for example, excimer lasers with laser media KrF, ArF or F2, with which projection light with a wavelength of 248 nm, 193 nm or 157 nm can be generated respectively. The structures 18 on the mask 14 within the illuminated region 16 are imaged onto the photosensitive layer 22 by means of the projection objective 20 . The photosensitive layer 22 , which can be, for example, a photoresist here, is applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com