Circular knitting machine

A technology of circular knitting machine and knitting machine, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of needle damage, mechanical loss, time-consuming maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

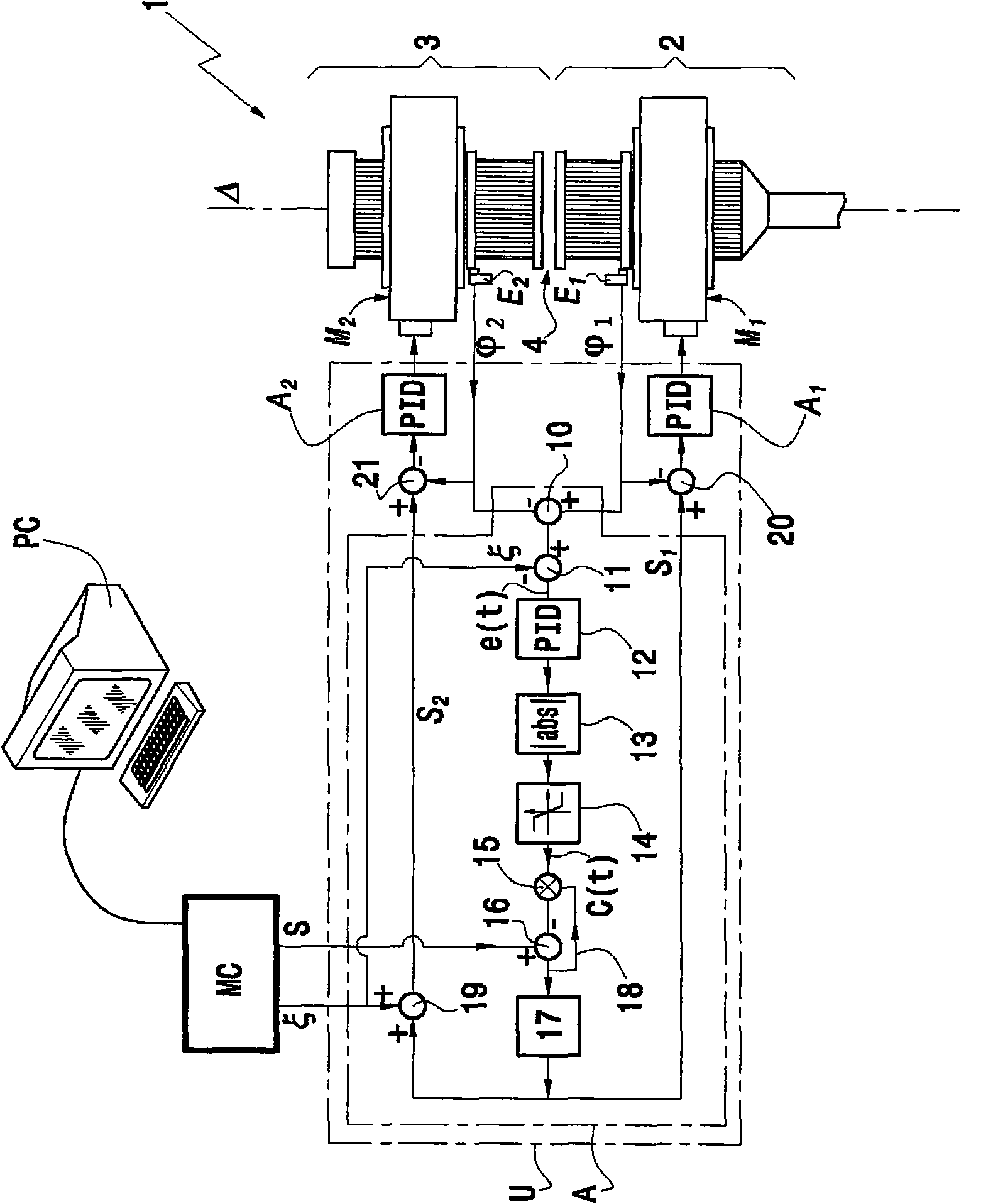

[0045] Such as figure 1 The circular knitting machine according to the invention shown and generally designated by reference numeral 1 comprises a lower cylinder 2 rotating about a vertical axis Δ. Above the lower cylinder 2 , the circular knitting machine 1 comprises a coaxial upper counterpart 3 also rotating about a vertical axis Δ. In the example shown, the circular knitting machine is a double cylinder knitting machine, the counterpart part 3 is also a cylinder with its needles (not shown) extending in its lower part, while the needles of the lower cylinder 2 are in this The upper portion of the barrel extends. The needles of the lower cylinder 2 and the upper cylinder 3 cooperate with each other to form knitting loops in the middle portion 4, for example to knit socks or other articles. According to techniques known to those skilled in the art, the needles are arranged in grooves of the upper and lower needle cylinders and can change position according to the knitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com