Process control method for iron discharge and reception of blast furnace

A blast furnace tapping and process control technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

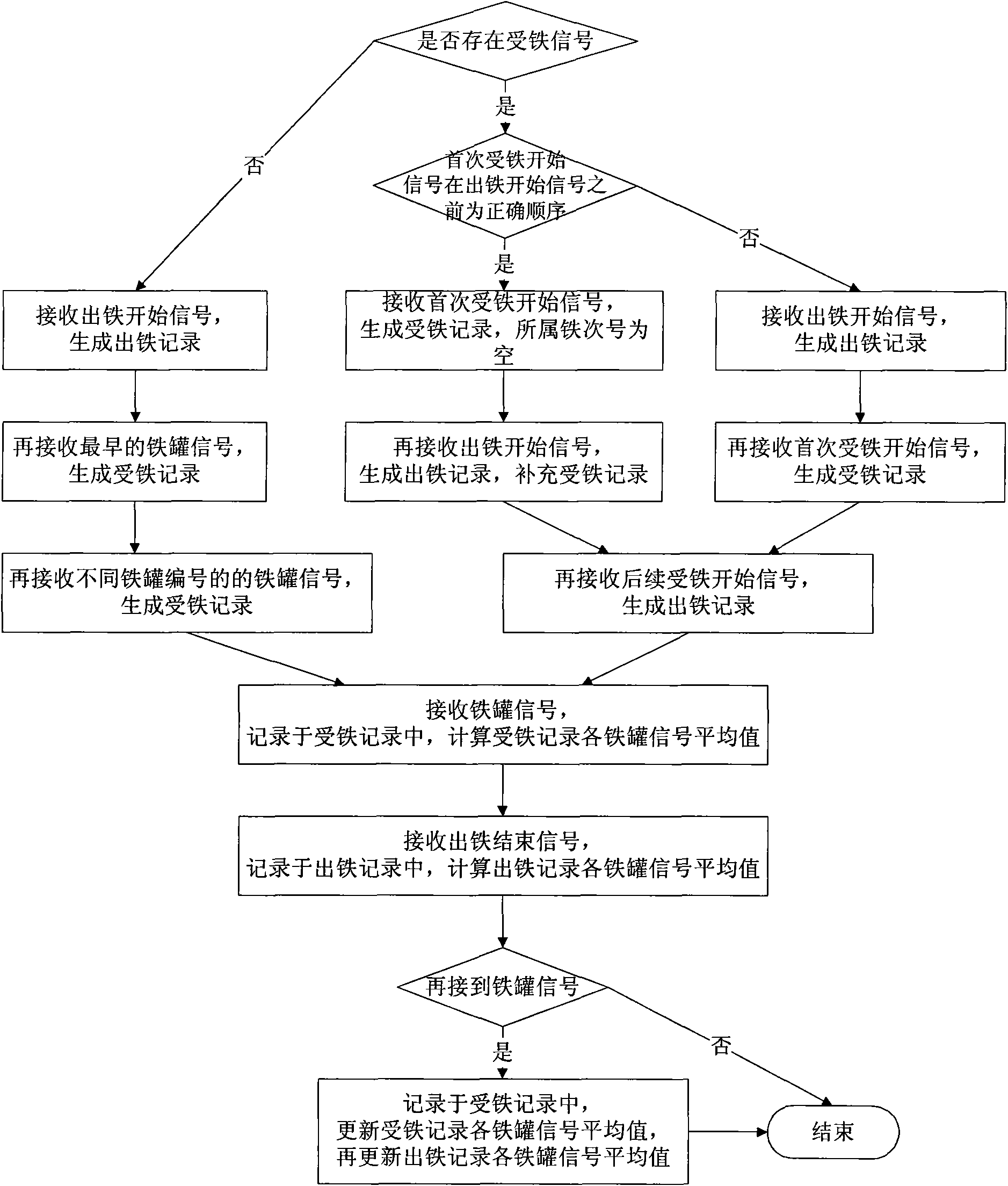

[0026] see figure 1 , the method of the present invention comprises the steps of:

[0027] In the first step, the process control system judges whether there is an iron receiving signal in the iron receiving process of the blast furnace, and gives the correct order of the first iron receiving start signal and the iron tapping start signal when there is an iron receiving signal.

[0028] There are three situations in the blast furnace iron receiving process: first, there is no iron receiving signal (the iron receiving signal includes the iron receiving start signal and the iron receiving end signal); second, there is an iron receiving signal, and the correct sequence is the first iron receiving start signal In the front, the iron tapping start signal is behind; third, there is the iron receiving signal; the correct sequence is that the iron tapping start signal comes first, and the first iron receiving start signal follows. These three situations are confirmed by this step, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com