Panel strip for vehicle

A molding and automotive technology, applied to vehicle parts, transportation and packaging, etc., can solve problems such as poor bonding, staggering, and high resistance of soft resin parts, and achieve the effect of preventing poor installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

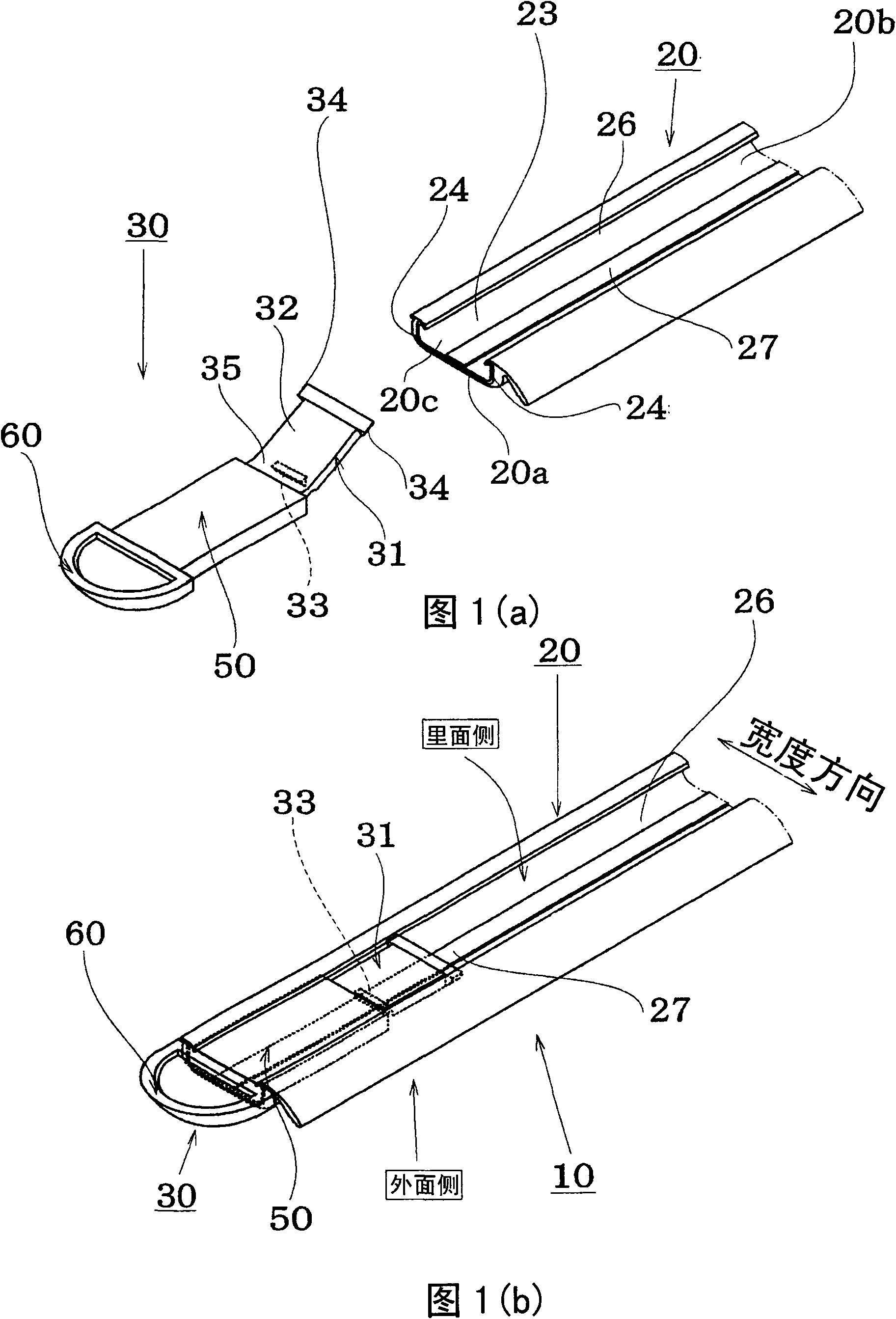

[0051] The automotive molding 10 of the present invention will be described with reference to the drawings.

[0052] Fig. 1(a) and Fig. 1(b) are explanatory diagrams of the molding 10 for automobiles, Fig. 1(a) shows the state before the end cap 30 is mounted on the molding main body 20, and Fig. 1(b) shows the end cap 30 The state of mounting on the molding body 20.

[0053] The molding main body 20 is in the shape of a C-shaped groove, and is manufactured by roll forming or the like.

[0054] The figures are drawn so that the inner surface 20b of the molding main body 20 faces upward and is viewed from the inner surface for easy understanding of the assembled state.

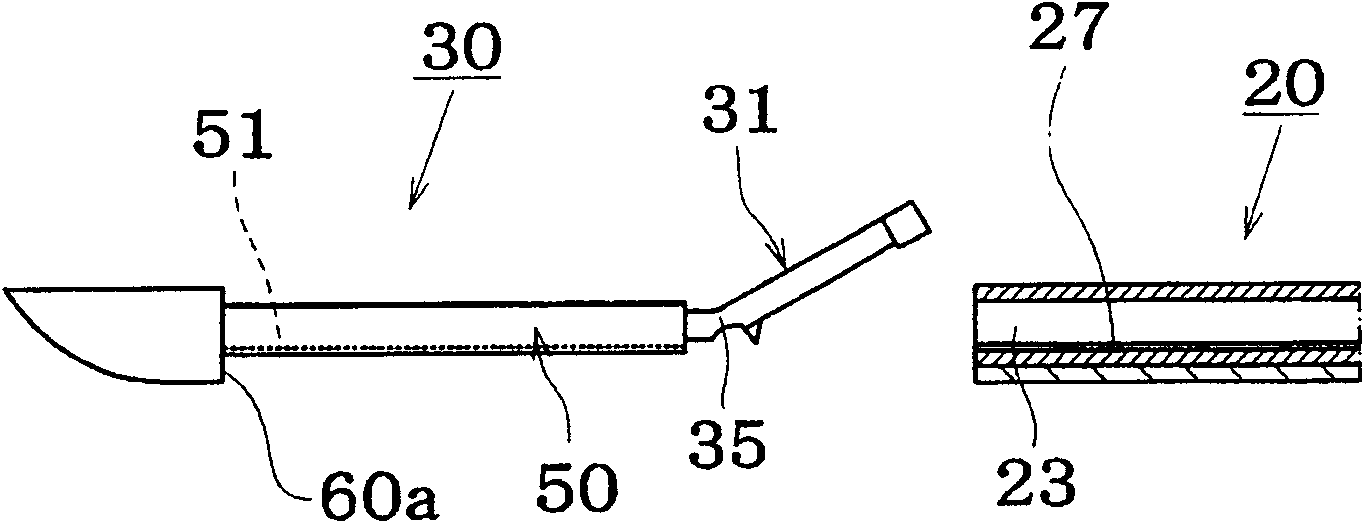

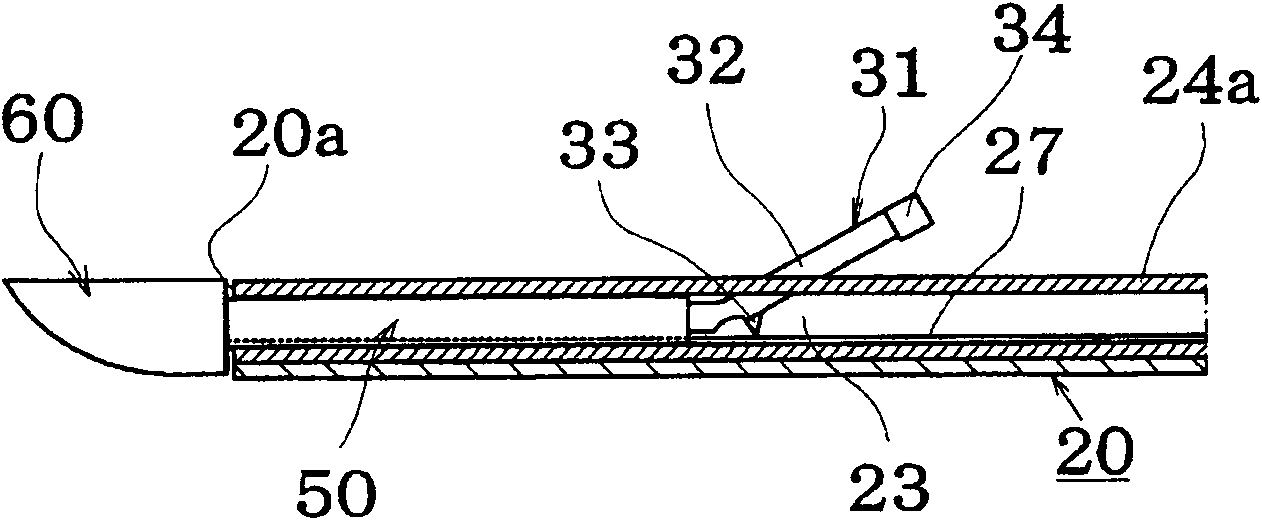

[0055] The end cap 30 is made of resin and is integrally formed by injection molding or the like, and has an insertion portion 50 , a rod portion 31 and a design portion 60 .

[0056] The insertion part 50 is inserted from the end opening 20c of the end 20a of the molding main body, and the rod part 31 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com