Plug-in strip type packing box

A packaging box and insert-type technology, applied in the field of insert-type packaging boxes, can solve the problems of inconvenient disassembly of packaging boxes, affecting the safety of goods, wasting wood, etc., and achieves the advantages of simple and fast installation, saving transportation costs, and firm and stable connections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

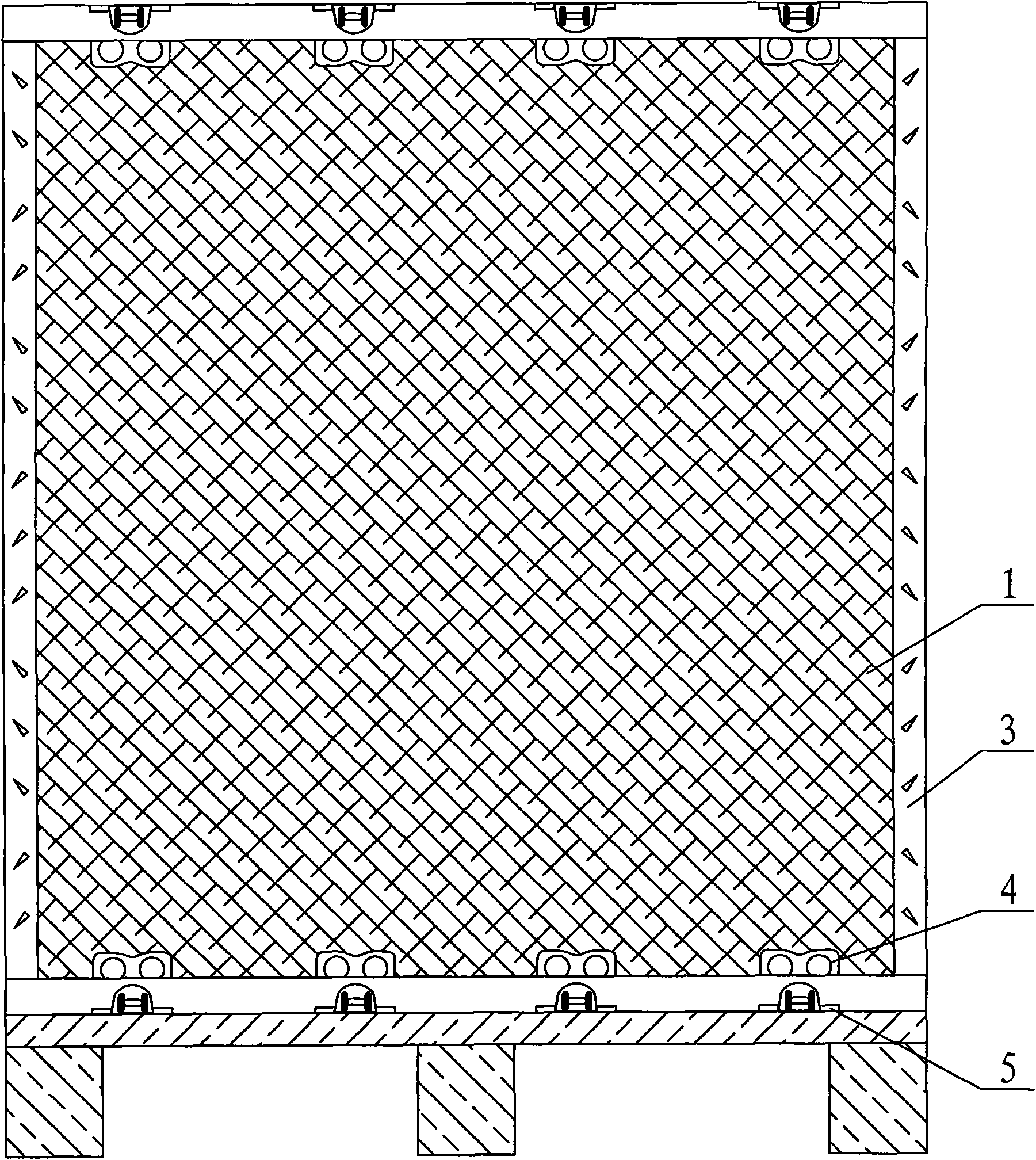

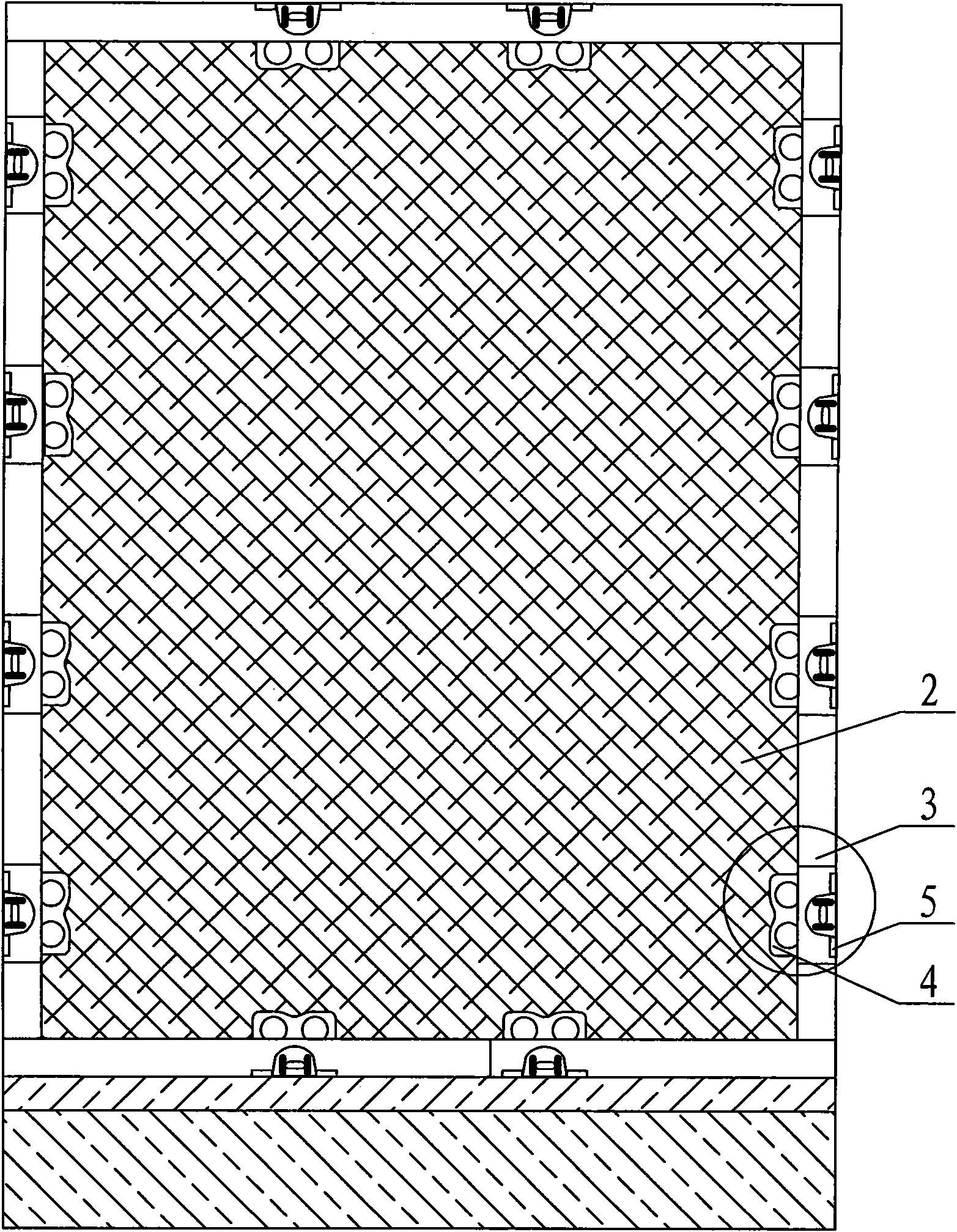

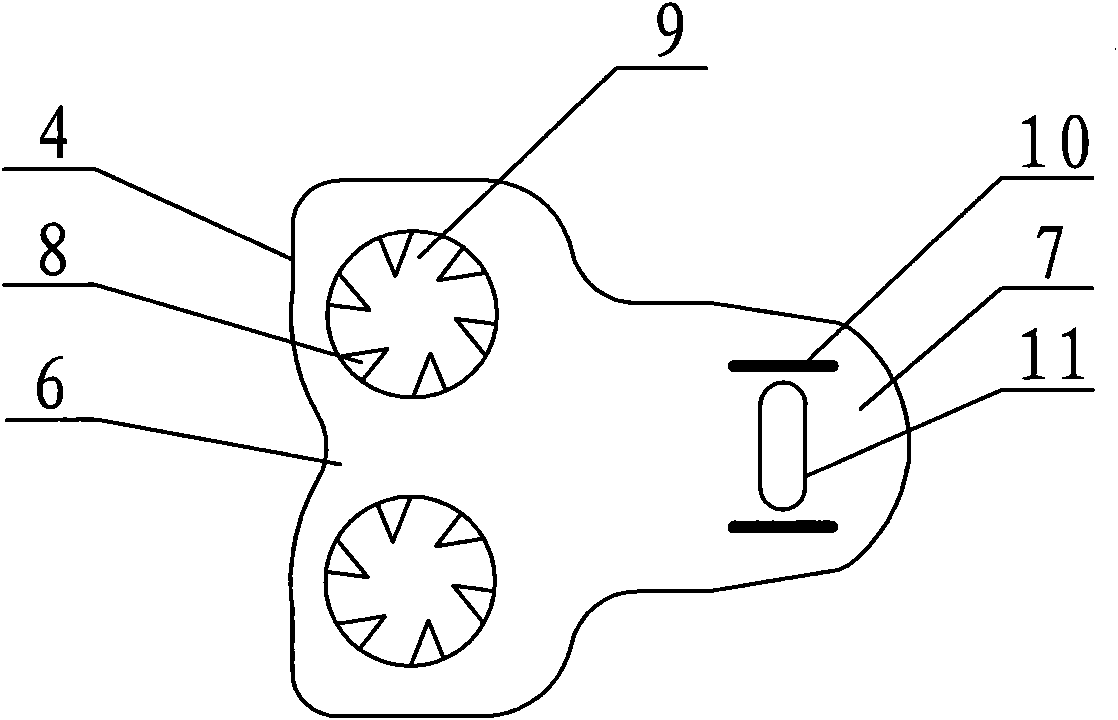

[0016] figure 1 , 2 Among them, a plug-in type packaging box is a packaging box assembled from six box panels. The adjacent two box panels are connected by "L"-shaped locking strips 3. The main box panel 1 and the side box panels The outer wall of 2 is provided with locking plate 4 at least one side. Such as image 3 As shown, the lock plate 4 includes a lock root 6 and a lock tongue 7. At least one punching hole 9 is punched on the lock root 6, and the positioning nails 8 distributed in the circumferential direction formed by punching the punching holes are in the shape of triangular sheets. All are embedded in the outer wall edge of the main box board or the side box board, and two anti-slip ribs 10 and an anti-slip hole 11 are stamped on the dead bolt 7 of the lock plate to improve the tensile strength. Such as Figure 4 As shown, a plurality of locking seams 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com