Conveyor with heating function

A conveyor and functional technology, applied in the field of conveyors, can solve the problems of increased floor area and cost, and achieve the effect of suppressing warping and deflection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

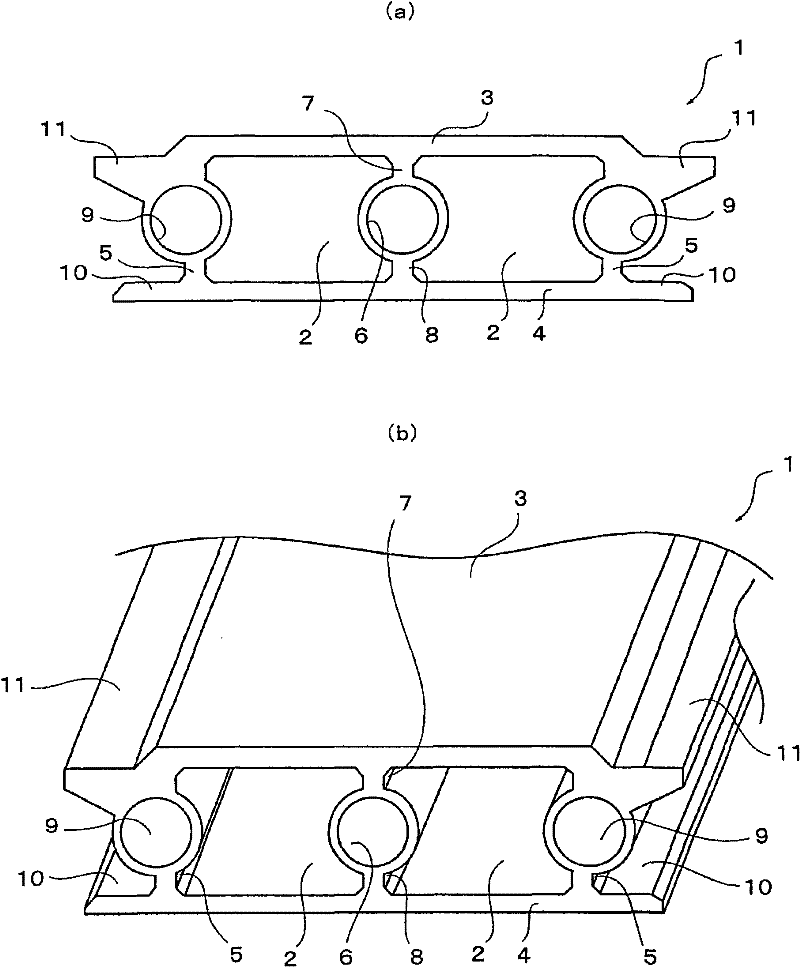

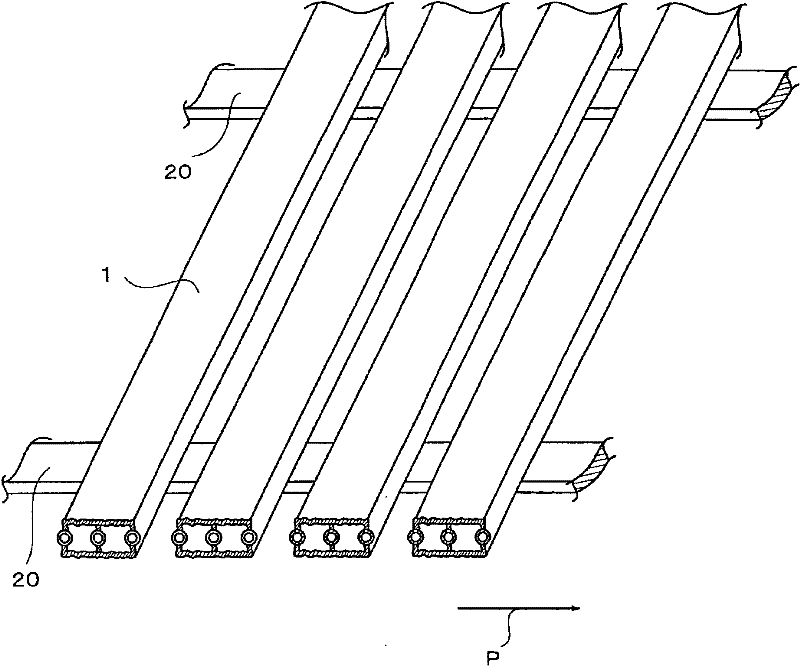

[0075] Next, a conveyor with a heating function according to Embodiment 1 of the present invention will be described. figure 1 (a) is a front view showing a section of an extruded piece cut out as one of the parts constituting the first embodiment, figure 1 (b) is a perspective view of the cut piece of the above-mentioned extruded part.

[0076] exist figure 1 Among them, the symbol 1 indicates that the extruded piece is cut into pieces. The extruded piece cutting block 1 is formed by forming an aluminum extrusion with a roughly rectangular cross-section and a hollow interior (also called an aluminum extruded profile, which is formed by pressing aluminum that becomes soft when heated into a metal mold, and then becomes a slender shape. Formed by extruding in the state) cut to a specified length. The extrusion cutout 1 is, for example, an elongated box-shaped body in which both ends in the longitudinal direction are opened by cutting the above-mentioned aluminum extrusion to...

Embodiment 2

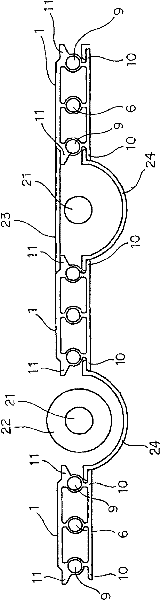

[0095] Next, a conveyor having a heating and cooling function according to a second embodiment of the present invention will be described. The basic structure of the second embodiment is the same as that of the above-mentioned embodiment 1, therefore, in the following description, only the parts different from the above-mentioned embodiment 1 will be described. Figure 9 (a) is a front view showing a section of an extruded piece cut out as one of the parts constituting the second embodiment, Figure 9 (b) is a perspective view of the cut piece of the above-mentioned extruded part.

[0096] exist Figure 9 Among them, the symbol 1 indicates that the extruded piece is cut into pieces. This extrusion cutout 1 is obtained by cutting an aluminum extrusion (elongated box-shaped body with openings at both ends in the longitudinal direction) having a substantially rectangular cross-section and a hollow inside. become.

[0097] exist Figure 9 Among them, symbol 2 is the hollow pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com