Spin-orbit-type reciprocating piston compressor

A reciprocating piston and compressor technology, applied in the field of compressors, can solve problems such as monotonous layout, piston reciprocating motion law cannot be designed according to needs, and swash plate compressors are not suitable for large-displacement compressors, so as to increase flexibility and structure The effect of compactness and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

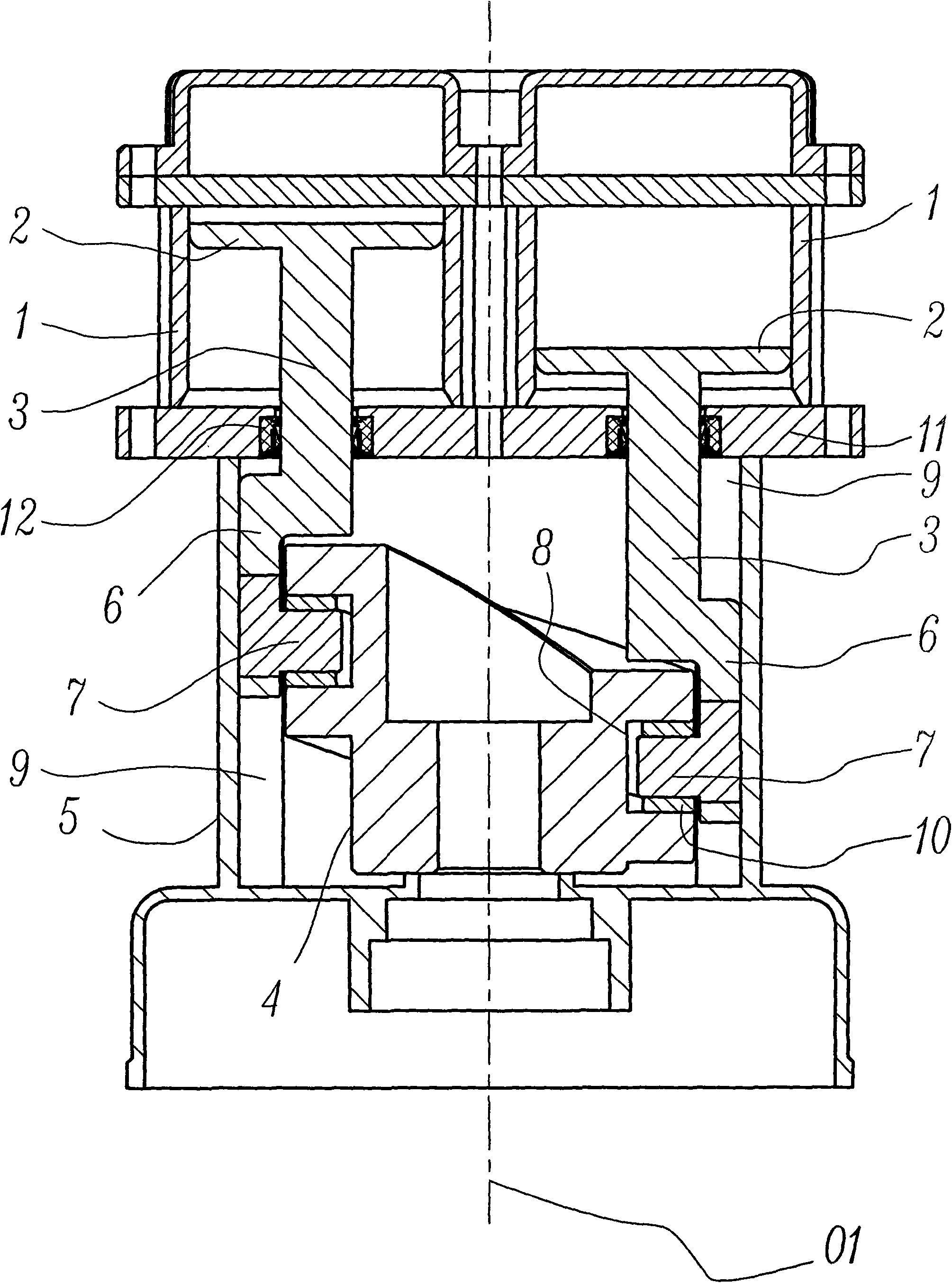

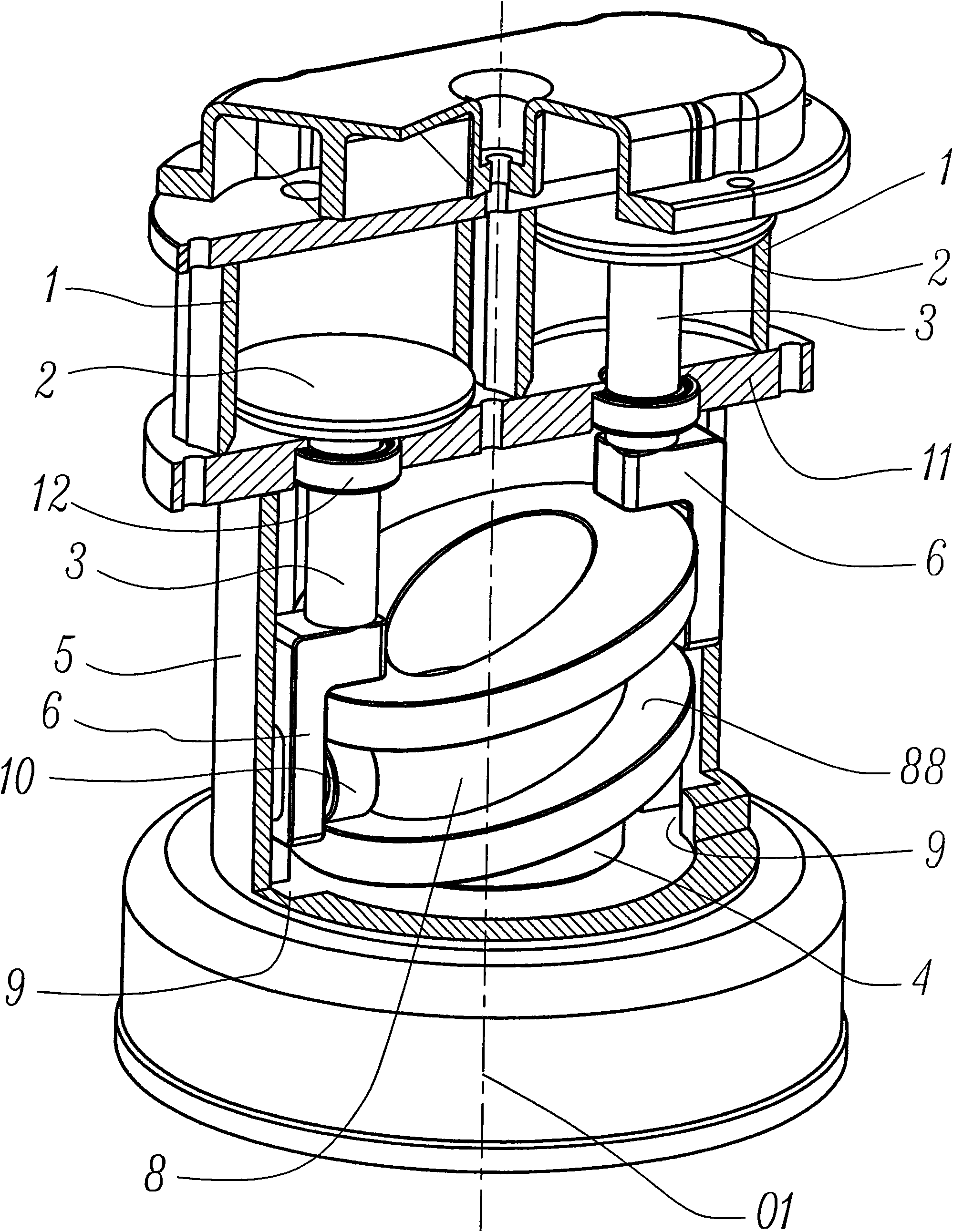

[0033] The present invention will be further described below with specific embodiment, see Figure 1-8 :

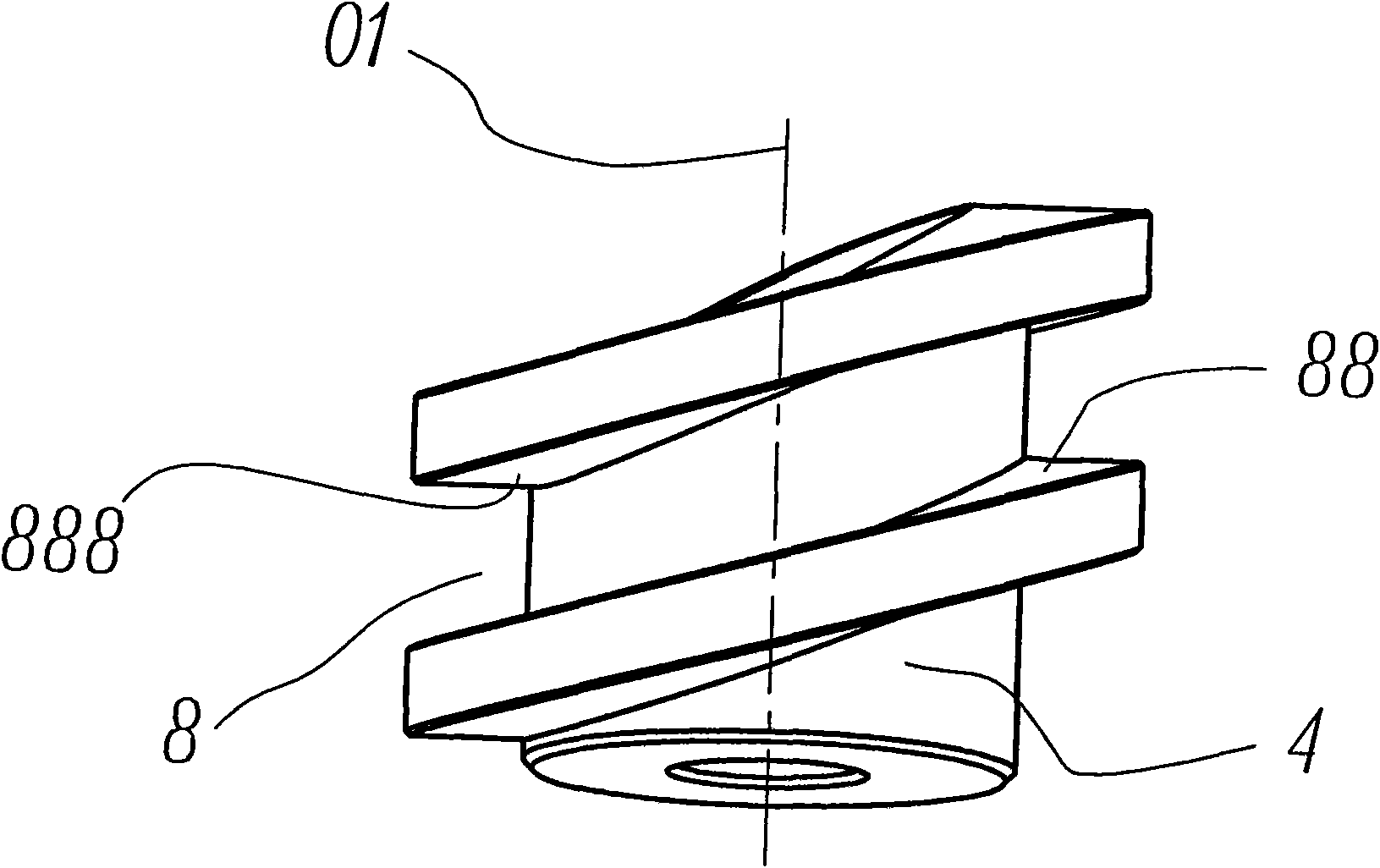

[0034] A rotary rail type reciprocating piston compressor, including a cylinder 1, a piston 2, a connecting rod 3, a rotor 4, a sliding seat 5, several sliders 6 and several thrust pins 7, the rotor 4 is driven by a motor, etc. The motor is driven to rotate, and a rotary rail 8 is provided on the rotor 4, and a working surface 88 is provided on the rotary rail 8; several slide rails 9 are provided on the slide seat 5, and all the slide rails 9 are straight. The concave rail (as shown in the figure) or convex rail (not shown in the figure) is arranged parallel to the axis O1 of the rotor 4, and the cross-sectional shape of the slide rail 9 can be a rectangular notch shape, a circular arc notch shape, or a triangular notch shape or trapezoidal notch shaped etc., like Figure 7 What is shown is a rectangular notch-shaped concave rail-shaped slide rail, which is shaped like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com