Differential pressure type density measurer and measuring method

A technology of density measurement and measurement method, which is applied in the determination of specific gravity by measuring pressure difference, which can solve the problems of large fluctuation of measurement data, great harm, and high price of radiation densitometers, so as to solve the problems of environmental pollution, low cost, and measurement. The effect of data stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

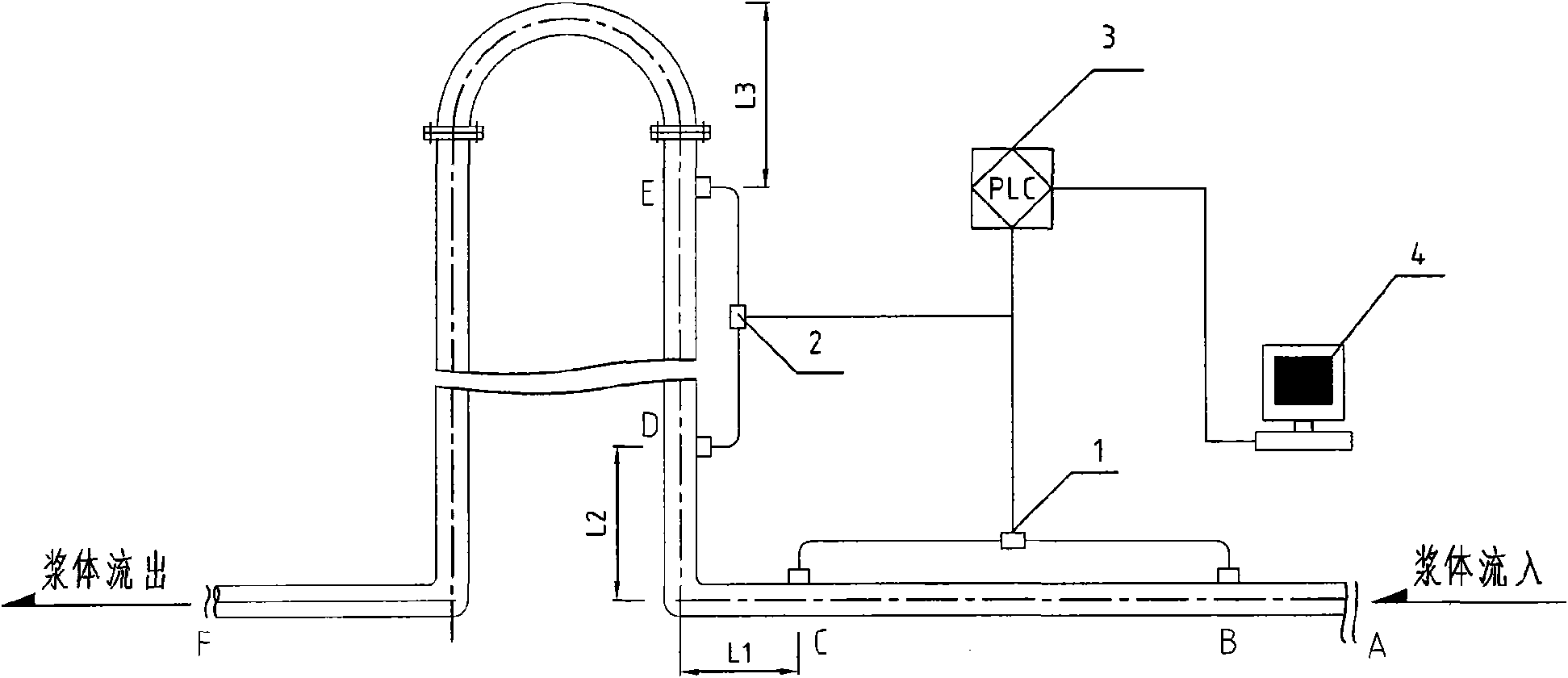

[0030] Such as figure 1 As shown, the differential pressure density measuring device described in this embodiment includes a horizontal pipeline differential pressure transmitter 1 installed in the horizontal pipeline test section and a vertical pipeline differential pressure transmitter 2 installed in the vertical pipeline test section. Both the signal output ends of the differential pressure transmitter 1 and the vertical pipeline differential pressure transmitter 2 are connected to the computer 4 through the programmable logic controller 3, and the computer 4 collects the output current mA of the two differential pressure transmitters online.

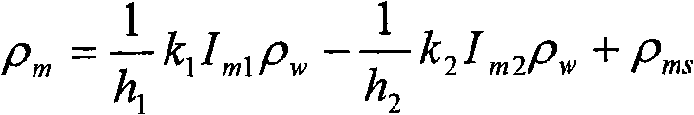

[0031] According to the hydraulic measurement requirements, the geometric dimensions of the differential pressure density measuring device and the installation dimensions of the differential pressure tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com