Continuous casting mold with coolant channel

A continuous casting crystallizer and coolant technology, which is applied in the field of continuous casting crystallizers, can solve the problems of low share, etc., and achieve the effects of improved heat transfer, increased life, and high heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

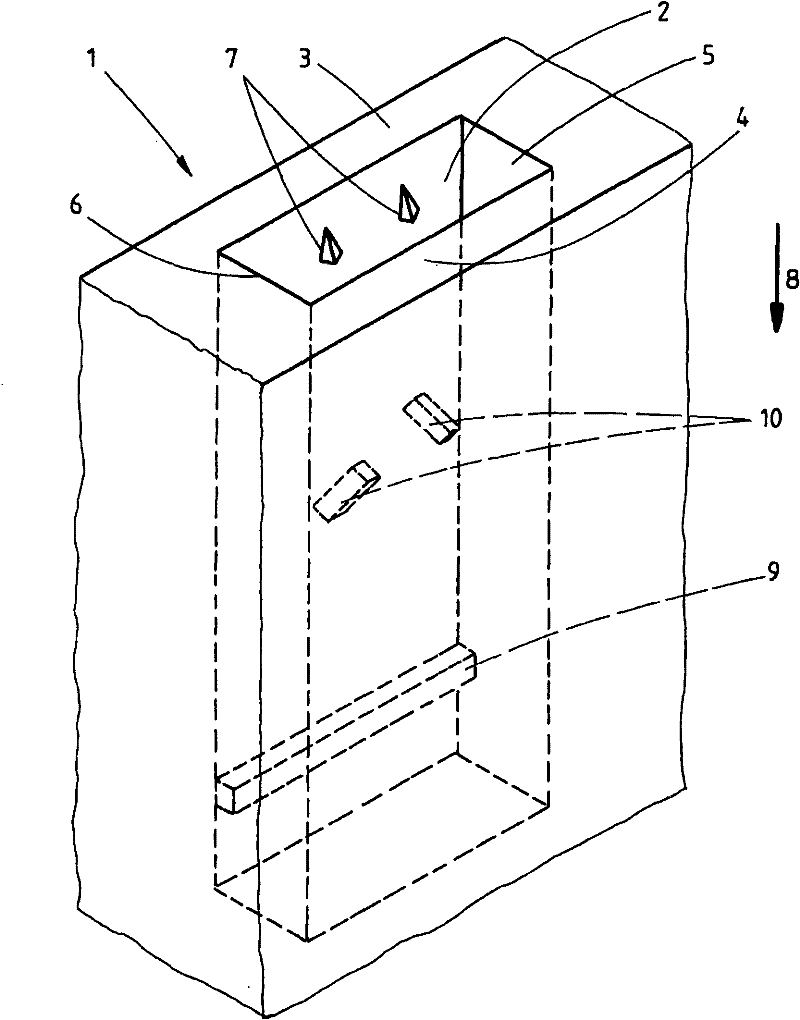

[0020] figure 1 Shown is a spatial representation of a part of a continuous casting mold 1 with a coolant channel 2 consisting of an inner mold wall 3 facing the molten metal on one side as the hot side and a mold side as the cold side The outer wall 4 is formed by a right side wall 5 and a left side wall 6 .

[0021] Swirl-generating elements 7 , 9 and 10 are arranged in flow direction 8 on inner mold wall 3 , ie on the hot side, and protrude into coolant channels 2 .

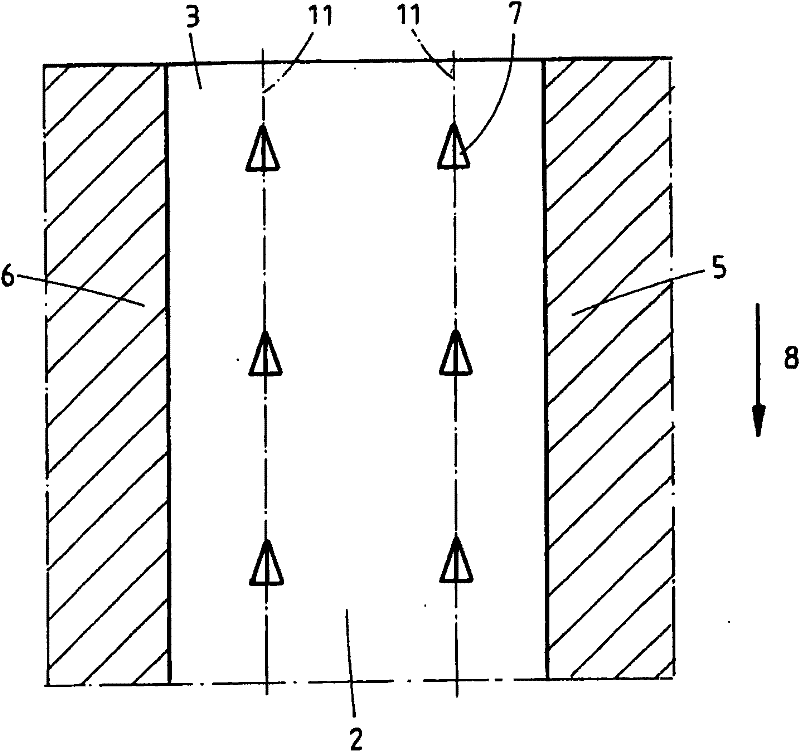

[0022] figure 2 A cutaway front view of the coolant channel 2 is shown, in which the tetrahedral vortex-generating elements 7 are arranged in two rows 11 on the mold inner wall 3 . The tetrahedrons point with their tips in the opposite direction to the flow direction 8 . With this arrangement, a progressive resistance is produced. Behind the tetrahedron the coolant is in a vortex. The tetrahedrons can also be arranged in a staggered manner.

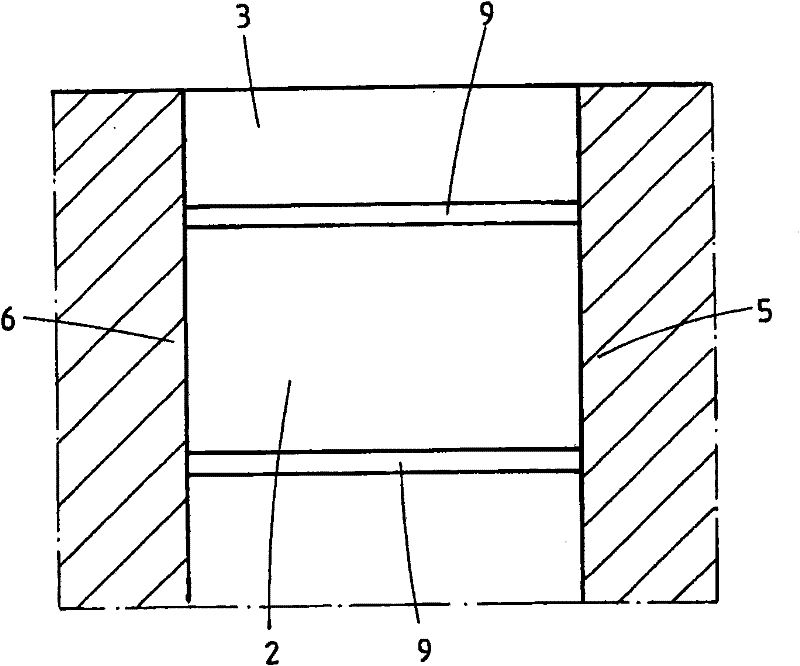

[0023] image 3 The vortex-generating elements 9 in the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com