Electron beam radiation curing coating for wooden floor

A technology of electron beam irradiation and electron beam curing, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of lack of environmental protection, affecting the practical application of WPC technology, and the ability to resist oxygen polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An electron beam radiation curing wood floor coating, comprising the following composition and components in terms of mass fraction: 50 parts of epoxy acrylate prepolymer, 30 parts of castor oil alkyd resin, 1 part of auxiliary agent; 1,4-butyl 13 parts of glycol divinyl ether, 10 parts of nano-silica functional filler, the coating is suitable for solid wood flooring.

[0037] The additive is a mixture of defoaming agent, rheology additive and anti-wear agent in a mass ratio of 1:1:1.5.

[0038] The rheological additive is a high molecular natural polymer, the defoamer is BYK-054, and the anti-wear agent is polydimethylsiloxane.

[0039] The preparation method of this electron beam radiation curing wooden floor coating comprises the following steps:

[0040] (1) Preparation of epoxy acrylate prepolymer

[0041] Put the epoxy resin E44 into the reaction kettle, stir and heat to 95°C. Under the protection of nitrogen, add acrylic acid containing tetraethylammonium bromi...

Embodiment 2

[0044] An electron beam radiation curing wood floor coating, according to the mass fraction, comprising the following composition and components: 70 parts of epoxy acrylate prepolymer, 45 parts of castor oil alkyd resin, 5 parts of auxiliary agent; 1,4-butyl 20 parts of glycol divinyl ether, 5 parts of nano-alumina functional filler.

[0045] The additive is a mixture of defoaming agent, rheology additive and anti-wear agent in a mass ratio of 1:1:1.5.

[0046] The rheological additive is a high molecular natural polymer, the defoamer is BYK-054, and the anti-wear agent is polydimethylsiloxane.

[0047] The preparation method of this electron beam radiation curing wooden floor coating comprises the following steps:

[0048] (1) Preparation of epoxy acrylate prepolymer

[0049] Put the epoxy resin E44 into the reaction kettle, stir and heat to 95°C. Under the protection of nitrogen, add acrylic acid containing tetraethylammonium bromide and p-hydroxyanisole and stir for 6 hours...

Embodiment 3

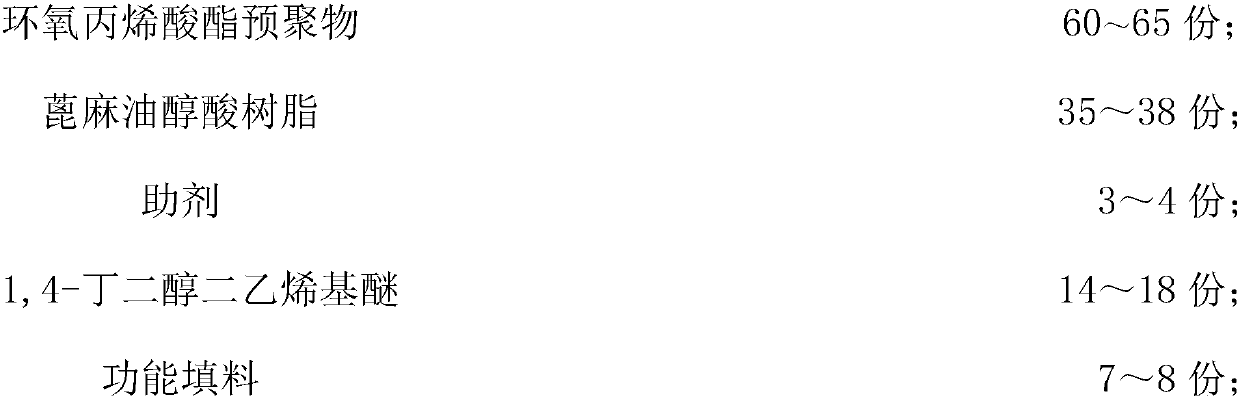

[0052] An electron beam radiation curing wood floor coating, comprising the following composition and components in terms of mass fraction: 60 parts of epoxy acrylate prepolymer, 35 parts of castor oil alkyd resin, 4 parts of auxiliary agent; 1,4-butyl 18 parts of glycol divinyl ether, 8 parts of nano-zinc oxide functional filler, the coating is suitable for multi-layer composite floor.

[0053] The additive is a mixture of defoaming agent, rheology additive and anti-wear agent in a mass ratio of 1:1:1.5.

[0054] The rheological additive is a high molecular natural polymer, the defoamer is BYK-054, and the anti-wear agent is polydimethylsiloxane.

[0055] The preparation method of this electron beam radiation curing wooden floor coating comprises the following steps:

[0056] (1) Preparation of epoxy acrylate prepolymer

[0057] Put the epoxy resin E44 into the reaction kettle, stir and heat to 95°C. Under the protection of nitrogen, add acrylic acid containing tetraethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com