Plunger for holding and moving electrical components in particular ic's

An electronic device and plunger technology, which is applied in electrical components, electronic circuit testing, single semiconductor device testing, etc., can solve the problems of complex structure of head components, achieve small structure size, eliminate heat loss, and achieve the effect of temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

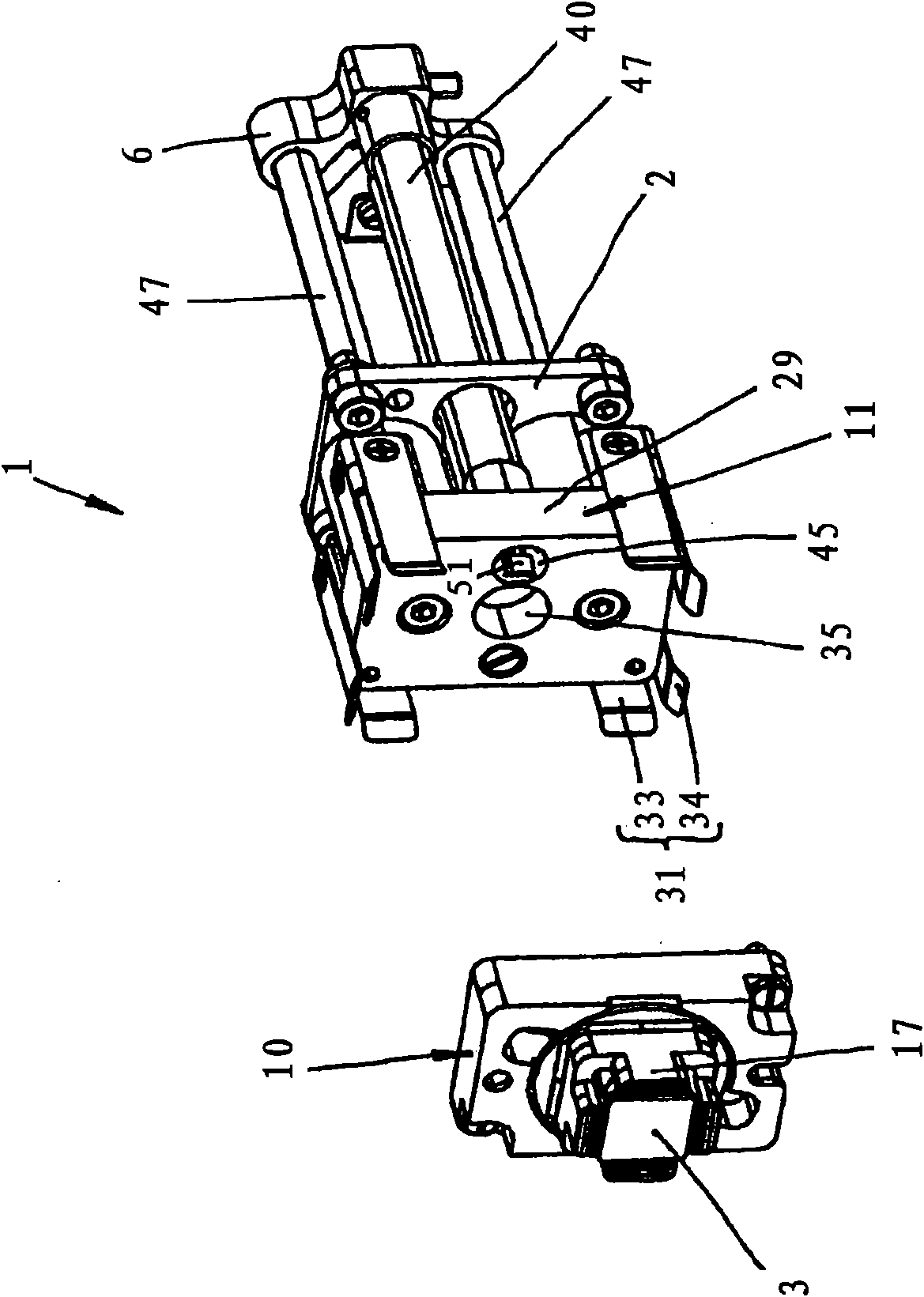

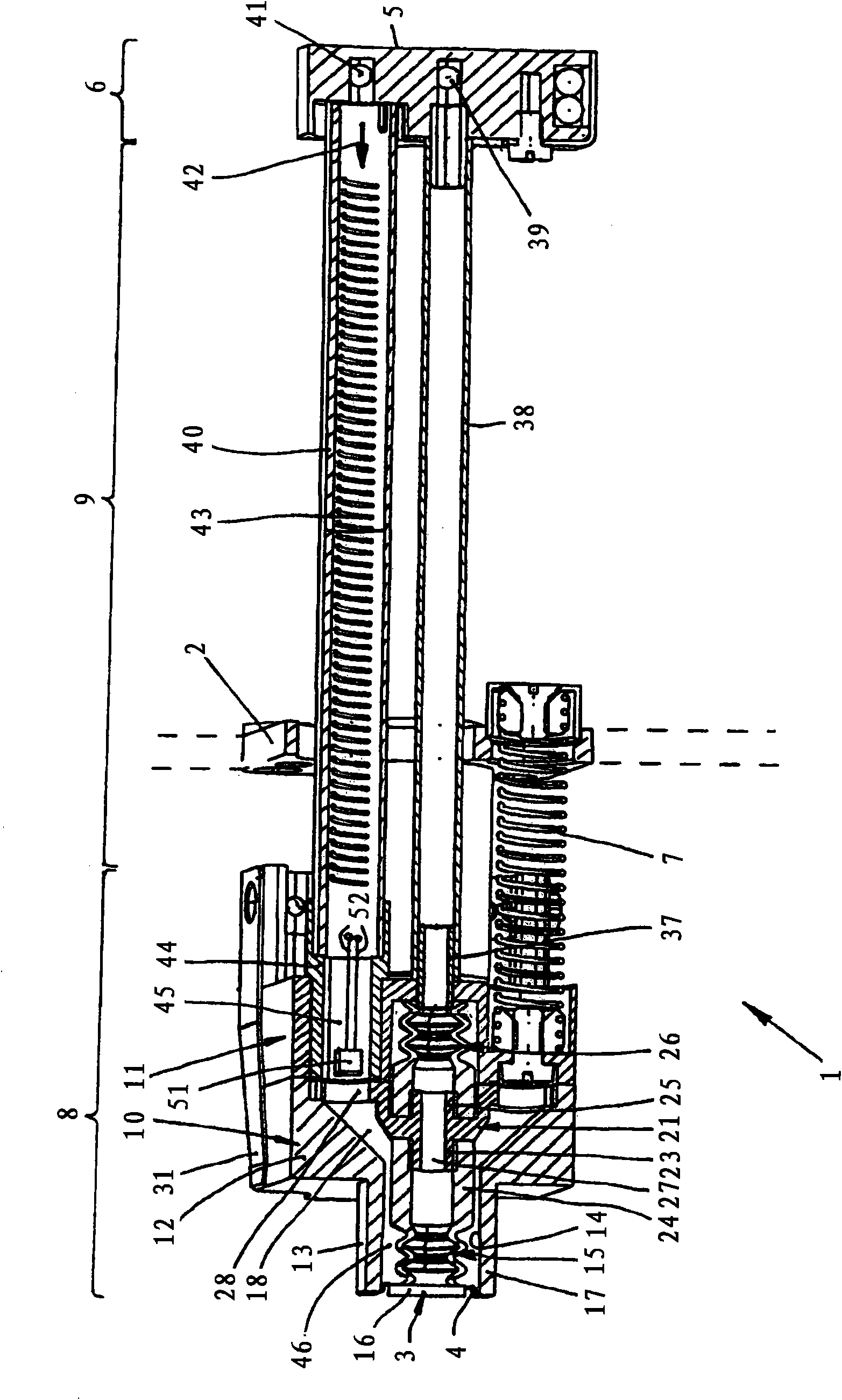

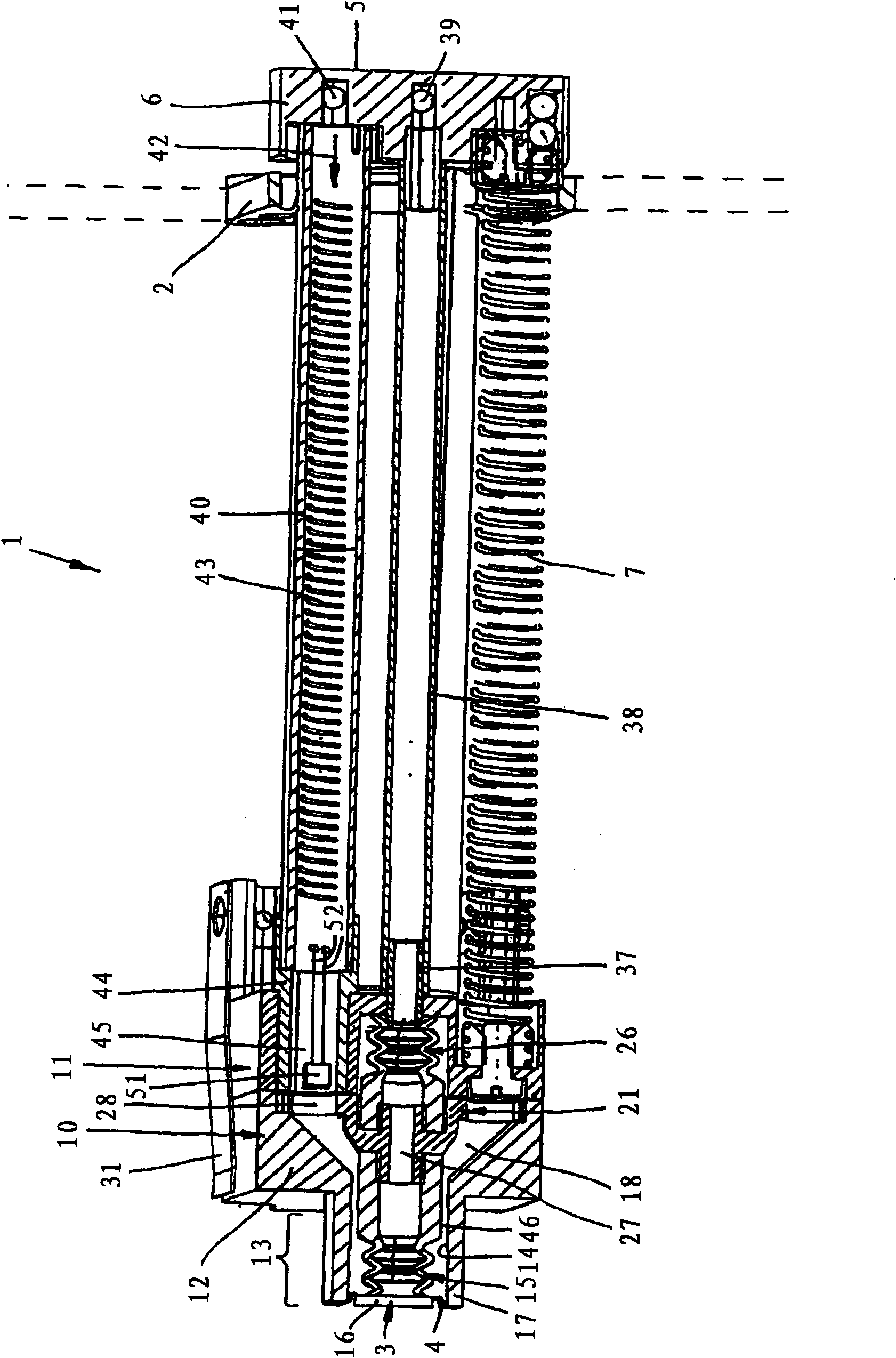

[0031] Depend on Figures 1 to 3 The plunger 1 can be seen, which is guided longitudinally displaceably on a plunger guide 2 . The plunger guide 2 can be fastened in a manner not shown, for example, on a circular carriage or a swinging device, by means of which the plunger 1 with the electronic components to be tested placed on the plunger 1 3 Move to a position where plunger 1 can move linearly (in figure 2 with 3 Middle left) to the contact position, in this position, each connecting leg 4 (pins) of the device 3 (see Figure 11 ) are placed on corresponding, not shown connecting contacts of a contact device (contact socket). The plunger 1 is therefore a holding device for the holding device 3, which can be piston-like in the figure 2 The retracted position shown in the image 3 Move back and forth between the previous positions shown in . The forward movement here is effected by a feed device (not shown) which presses against the rear face 5 of the rear end section 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com