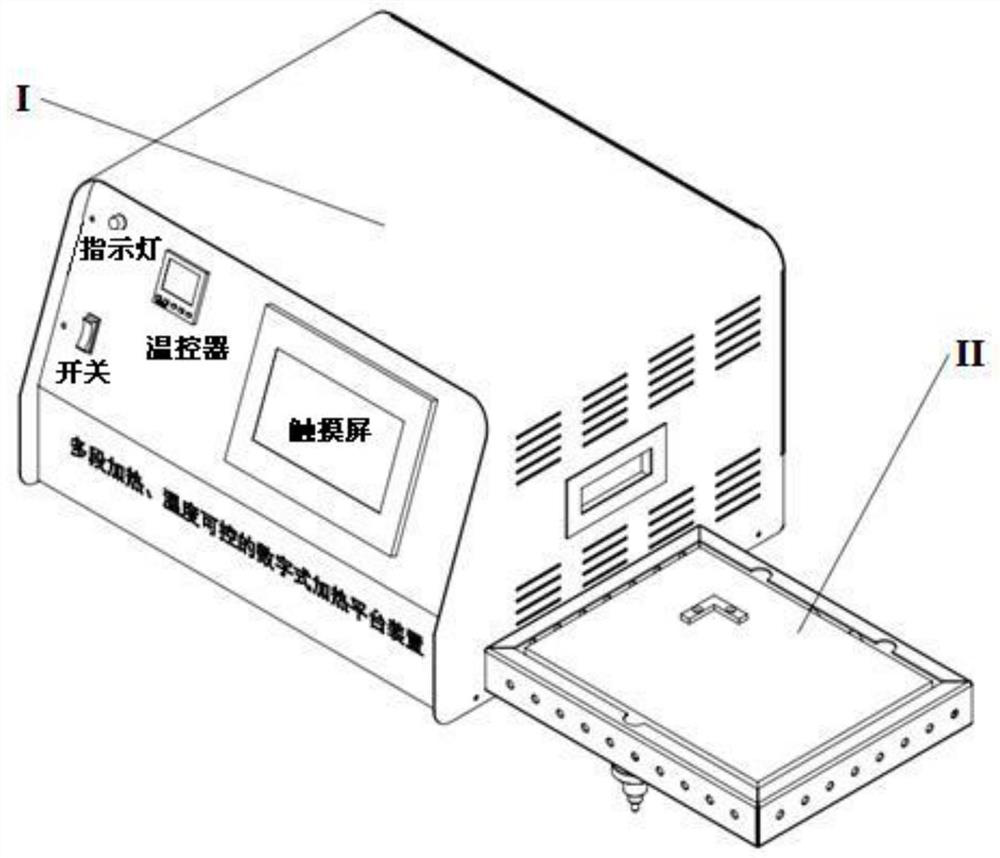

A multi-stage controllable heating platform device and heating control method

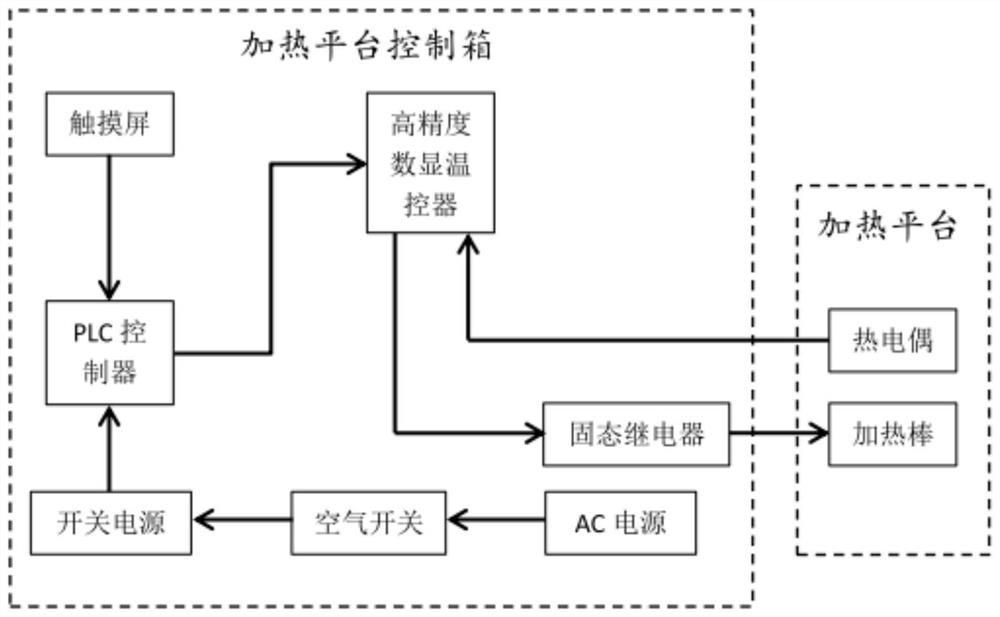

A heating platform and controllable technology, which is applied in the direction of electric heating devices, heating element shapes, ohmic resistance heating parts, etc., can solve problems such as complex structure, difficulty in realizing intelligence, automatic processing and manufacturing, and difficulty in integration, and achieve adjustment accuracy High, guarantee the effect of precision craft manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment takes the polyimide precursor material as an example to illustrate the multi-stage controllable heating control method of the present invention. The size of the material is 260 mm in length, 180 mm in width, and 20 mm in thickness, and 4 stages of heating are carried out in total. The first stage The heating temperature of the first stage is 55°C, the heating rate is 20°C / h, and the constant temperature time is 3h; the heating temperature of the second stage is 170°C, the heating rate is 40°C / h, and the constant temperature time is 2h; the heating temperature of the third stage is 220°C, the heating rate is 30°C / h, and the constant temperature time is 1h; the heating temperature of the fourth stage is 280°C, the heating rate is 30°C / h, and the constant temperature time is 0.5h, including the following steps:

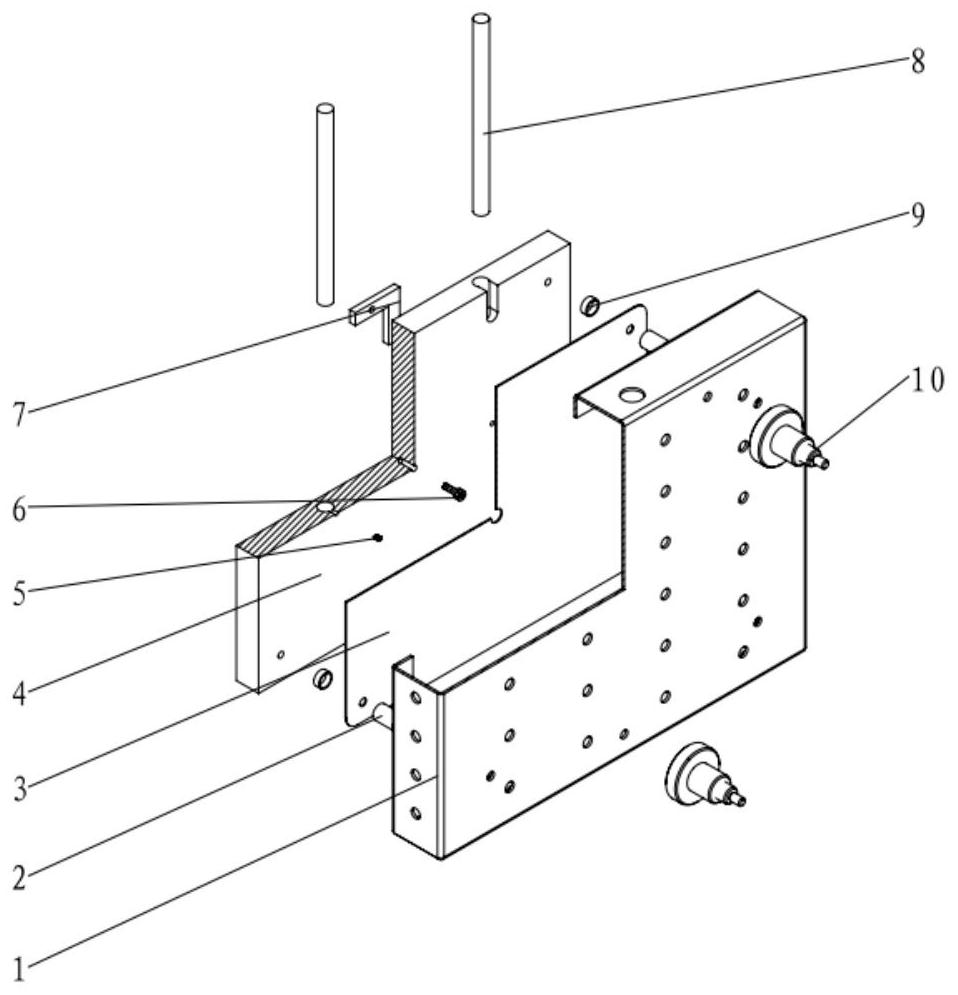

[0040] 1) Place the polyimide precursor material on the heating platform, and use the positioning piece to position the material, and then adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com