Active pure snake powder capsule and preparation technique thereof

A production process, pure snake powder technology, applied in capsule delivery, medical preparations containing active ingredients, antidote, etc., can solve the problems of loss of active ingredients, waste of precious resources, and difficulty in retaining active ingredients, so as to delay aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

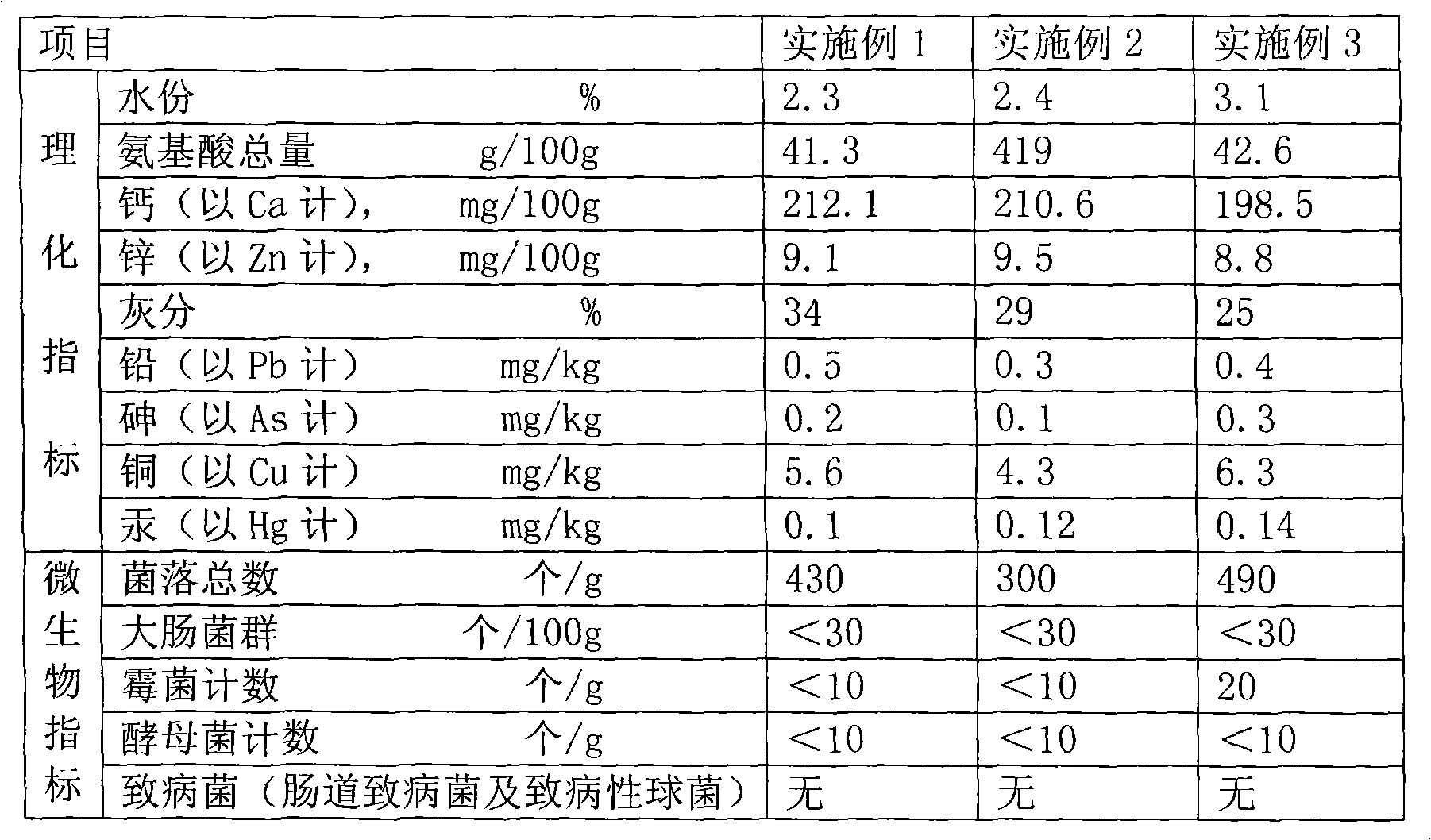

Examples

Embodiment 1

[0030] An active pure snake powder capsule is prepared from the lyophilized powder of the pit viper and the lyophilized powder of the black snake in a weight ratio of 2.33:1.

[0031] The manufacturing process steps of active pure snake powder capsules are as follows:

[0032] 1) Material selection: take fresh pit viper and fresh black-headed snake, remove the head, peel the skin, remove the internal organs, and clean;

[0033] 2) Freezing: send the cleaned viper and black snake into a freeze dryer, and freeze for 8 hours at a temperature of -40°C;

[0034] 3) Vacuum drying: start the vacuum pump, under the state of vacuum degree of 5Pa, heat up for the first time, at 30 ° C, heat and sublime for 10 hours; for the second time, heat up, at 60 ° C, heat and sublime for 12 hours; The second heating, at 80 ℃, heating and sublimation for 10 hours;

[0035] 4) pulverizing: the vacuum-dried Pit viper and the black-headed snake are roughly crushed by rollers, respectively, and then ...

Embodiment 2

[0041] An active pure snake powder capsule is prepared from lyophilized powder of pit viper and lyophilized powder of blackhead snake in a weight ratio of 2:1.

[0042] The manufacturing process steps of active pure snake powder capsules are as follows:

[0043] 1) Material selection: take fresh pit viper and fresh black-headed snake, remove the head, peel the skin, remove the internal organs, and clean;

[0044] 2) Freezing: send the cleaned viper and black snake into a freeze dryer, and freeze for 9 hours at a temperature of -45°C;

[0045] 3) Vacuum drying: start the vacuum pump, under the state of vacuum degree of 1.3Pa, heat up for the first time, at 25 ℃, heat and sublime for 11 hours; heat up for the second time, at 55 ℃, heat and sublime for 13 hours; Three times of heating, at 75 ° C, heating and sublimation for 11 hours;

[0046] 4) pulverizing: the vacuum-dried Pit viper and the black-headed snake are roughly crushed by rollers, respectively, and then finely pulve...

Embodiment 3

[0052] An active pure snake powder capsule is prepared from the freeze-dried powder of the viper and the freeze-dried powder of the black-headed snake in a weight ratio of 3:1.

[0053] The manufacturing process steps of active pure snake powder capsules are as follows:

[0054] 1) Material selection: take fresh pit viper and fresh black-headed snake, remove the head, peel the skin, remove the internal organs, and clean;

[0055] 2) Freezing: send the cleaned viper and black snake into a freeze dryer, and freeze for 7 hours at a temperature of -35°C;

[0056] 3) Vacuum drying: start the vacuum pump, under the state of vacuum degree of 13Pa, heat up for the first time, at 35 ℃, heat and sublime for 9 hours; for the second time, heat up, at 65 ℃, heat and sublime for 11 hours; The second heating, at 85 ℃, heating and sublimation for 9 hours;

[0057] 4) pulverizing: the vacuum-dried Pit viper and the black-headed snake are roughly crushed by rollers, respectively, and then fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com