Cartridge device for automatic screen printing production line

A technology of screen printing and production line, which is applied in the direction of screen printing machine, printing, printing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the present invention more definite and detailed, the preferred embodiments are listed hereby in conjunction with the following diagrams, and the structure and technical characteristics of the present invention are described in detail as follows:

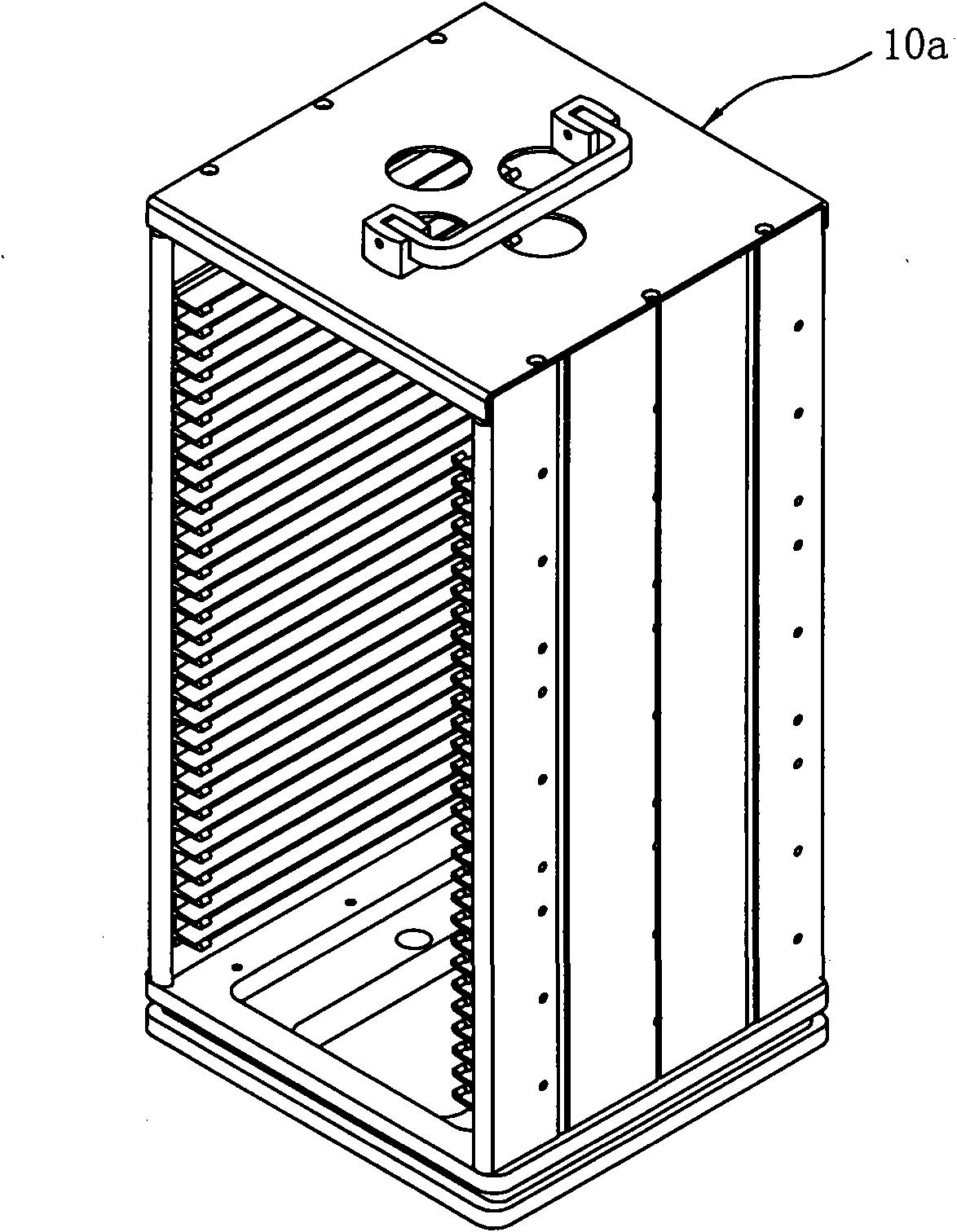

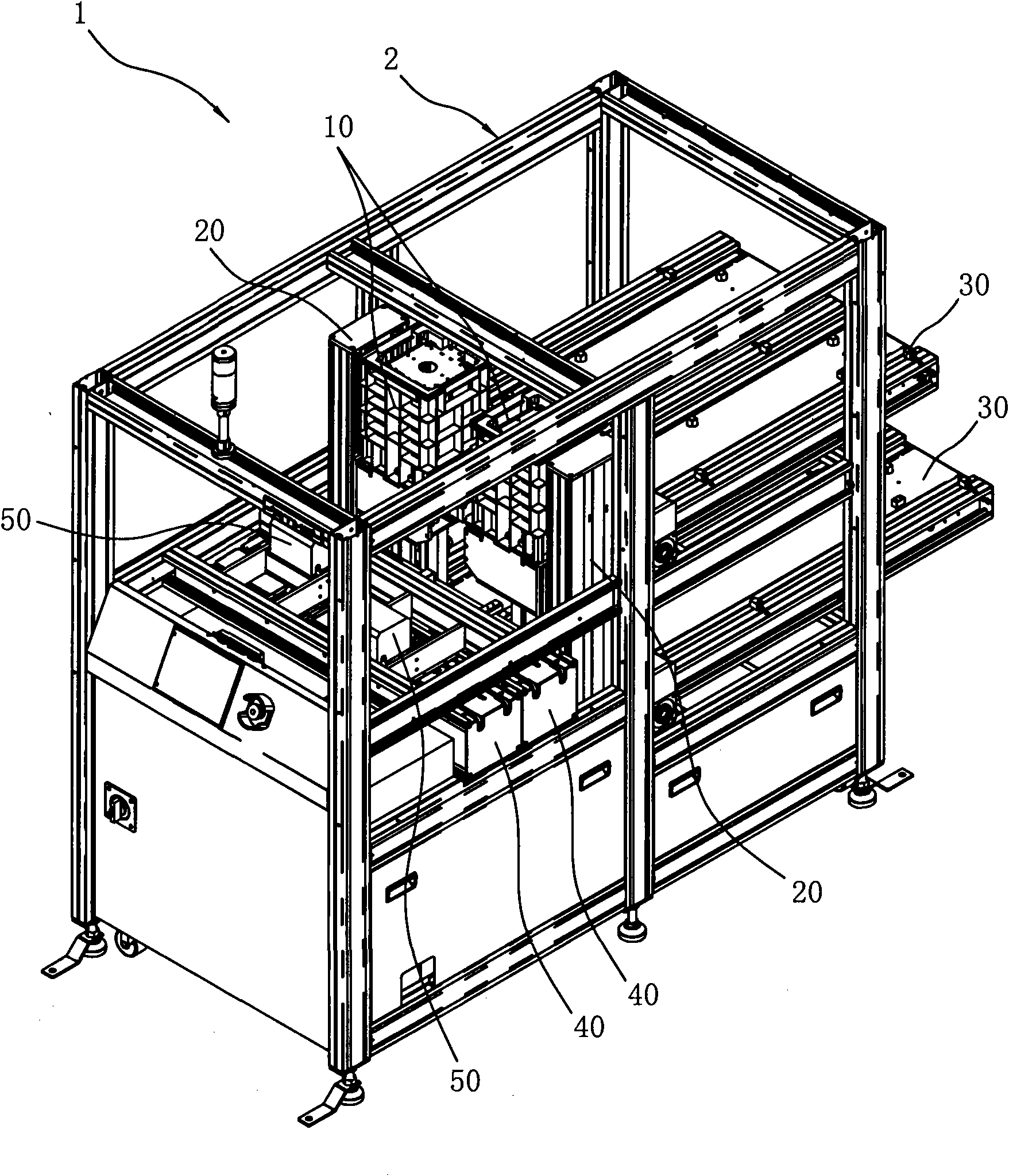

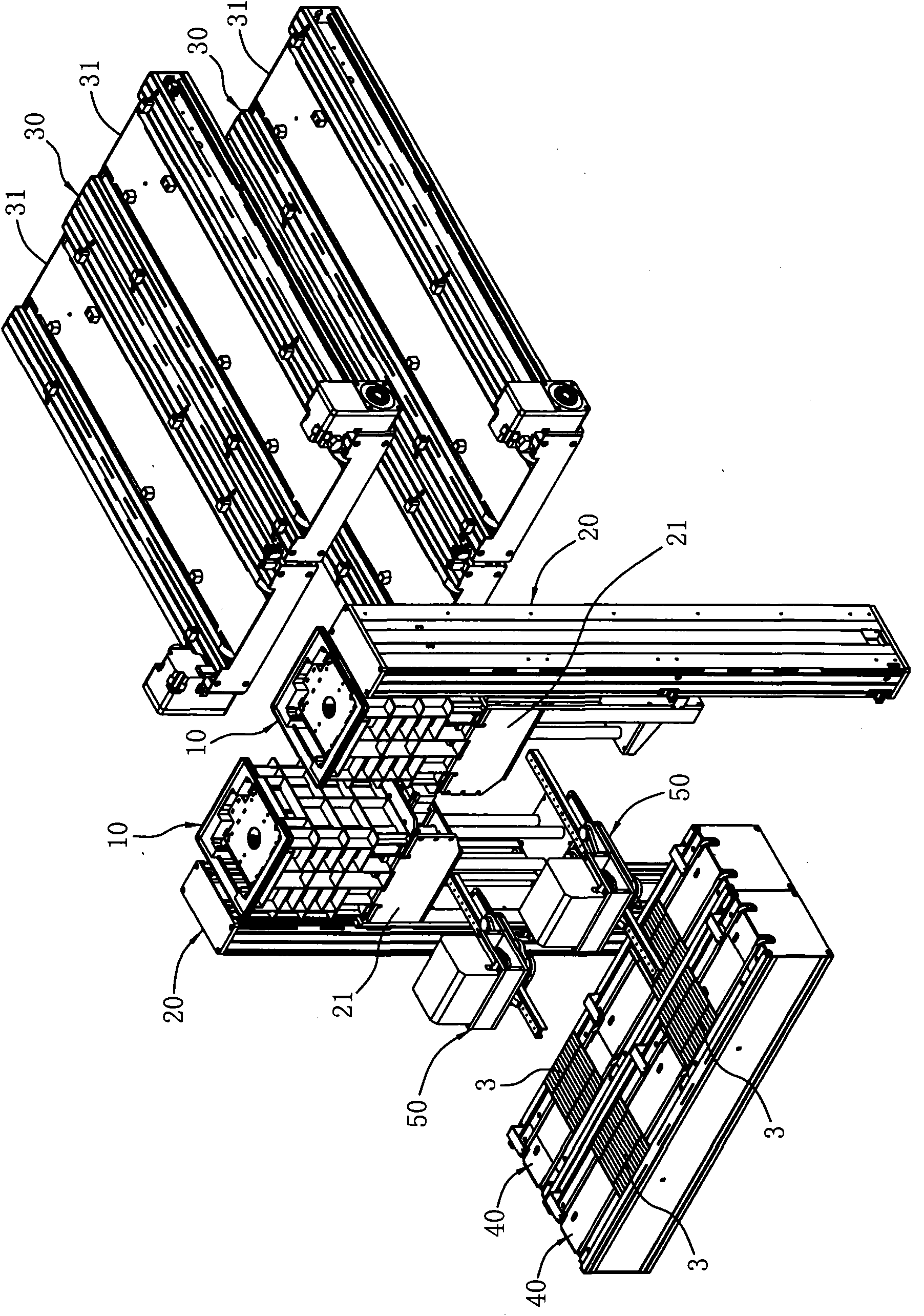

[0034] Please refer to Figure 2 to Figure 12 As shown, the cassette device 1 of the automatic screen printing production line of the present invention includes a frame body 2, a plurality of cassettes 10, two cassette lifting mechanisms 20, two cassette carrying mechanisms 30, two printed matter transfer Loading mechanism 40 and two displacement mechanisms 50, wherein, the frame body 2 is a structure formed by combining metal frame materials such as aluminum extruded frame materials, which is light in weight and not easily deformed, and can accommodate cards Cassette lifting mechanism 20, cassette carrying mechanism 30, printed matter transfer mechanism 40 and displacement mechanism 50 to reduce its configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com