Installing method of roof mast

An installation method and mast technology, applied in the processing of building materials, building types, buildings, etc., can solve the problems of inapplicability to large-scale mast installation, low installation efficiency and safety, complicated mast installation methods, etc., and achieve easy management at all levels , Reduce the difficulty and cost of hoisting, and improve the effect of construction quality

Active Publication Date: 2011-01-05

CHANGZHOU NO 1 CONSTR GRP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The shortcomings of the above-mentioned prior art are: the installation method of the above-mentioned mast is relatively complicated, the installation cost is high, the installation efficiency and safety are low, and it cannot be applied to the installation of large-scale masts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

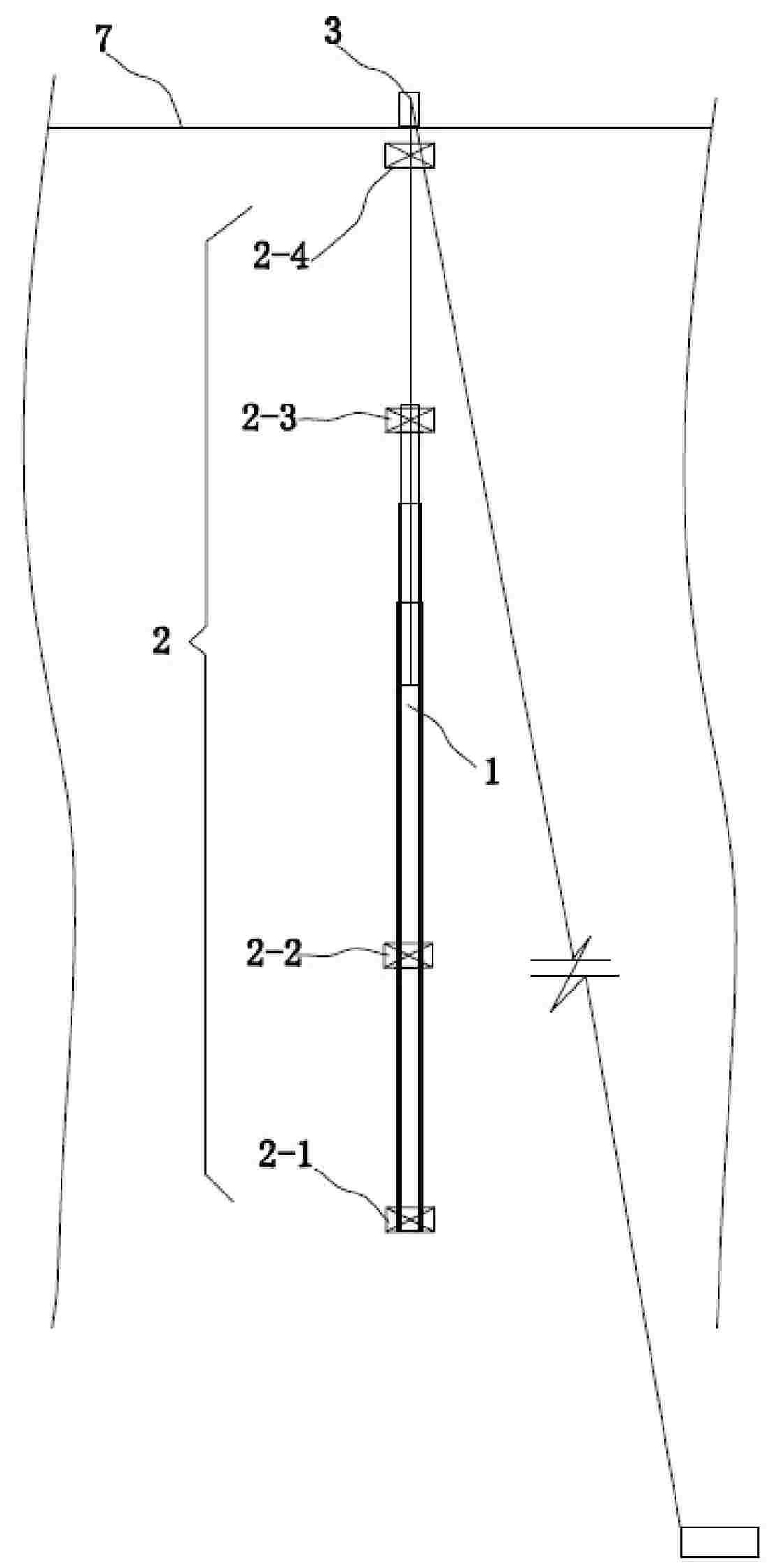

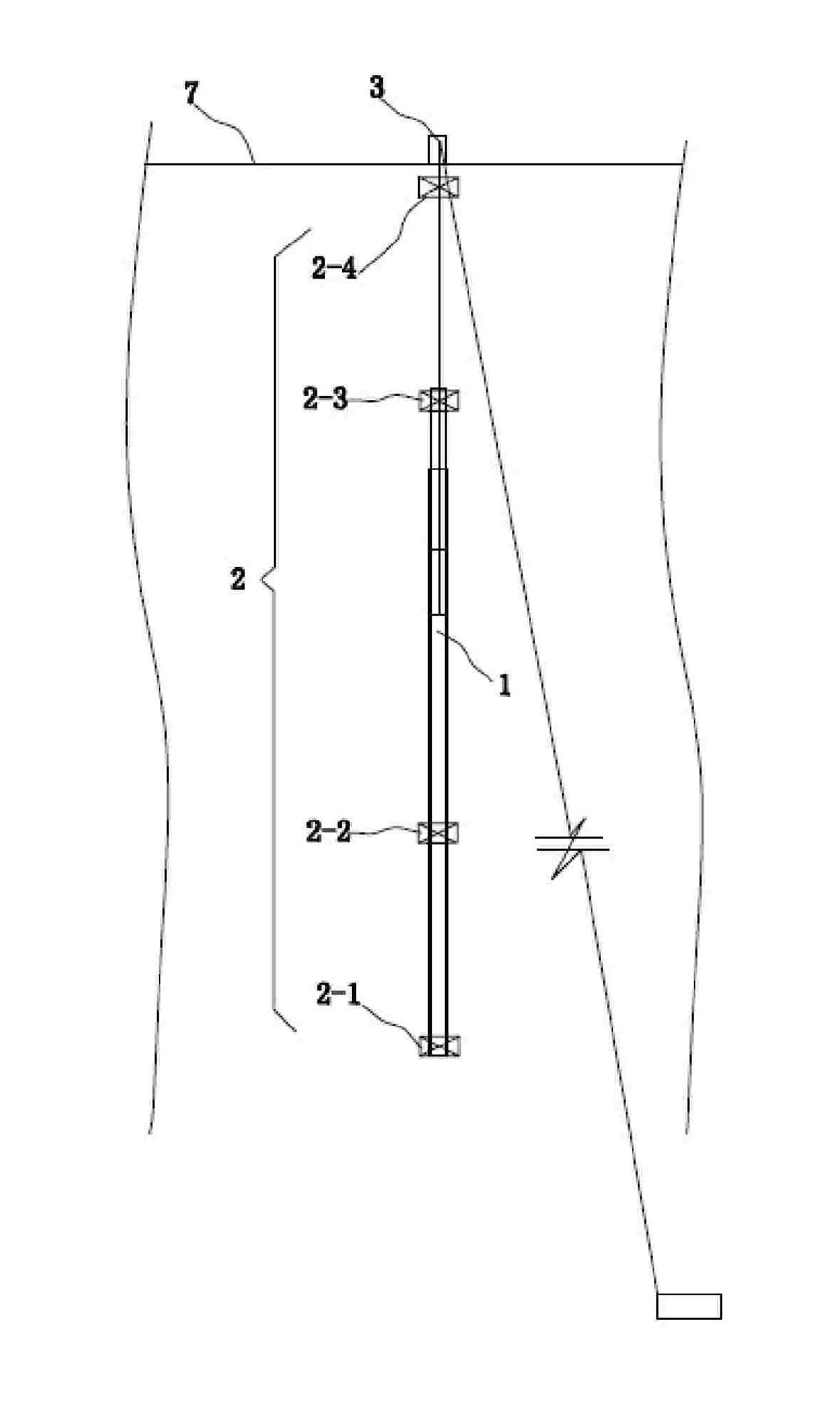

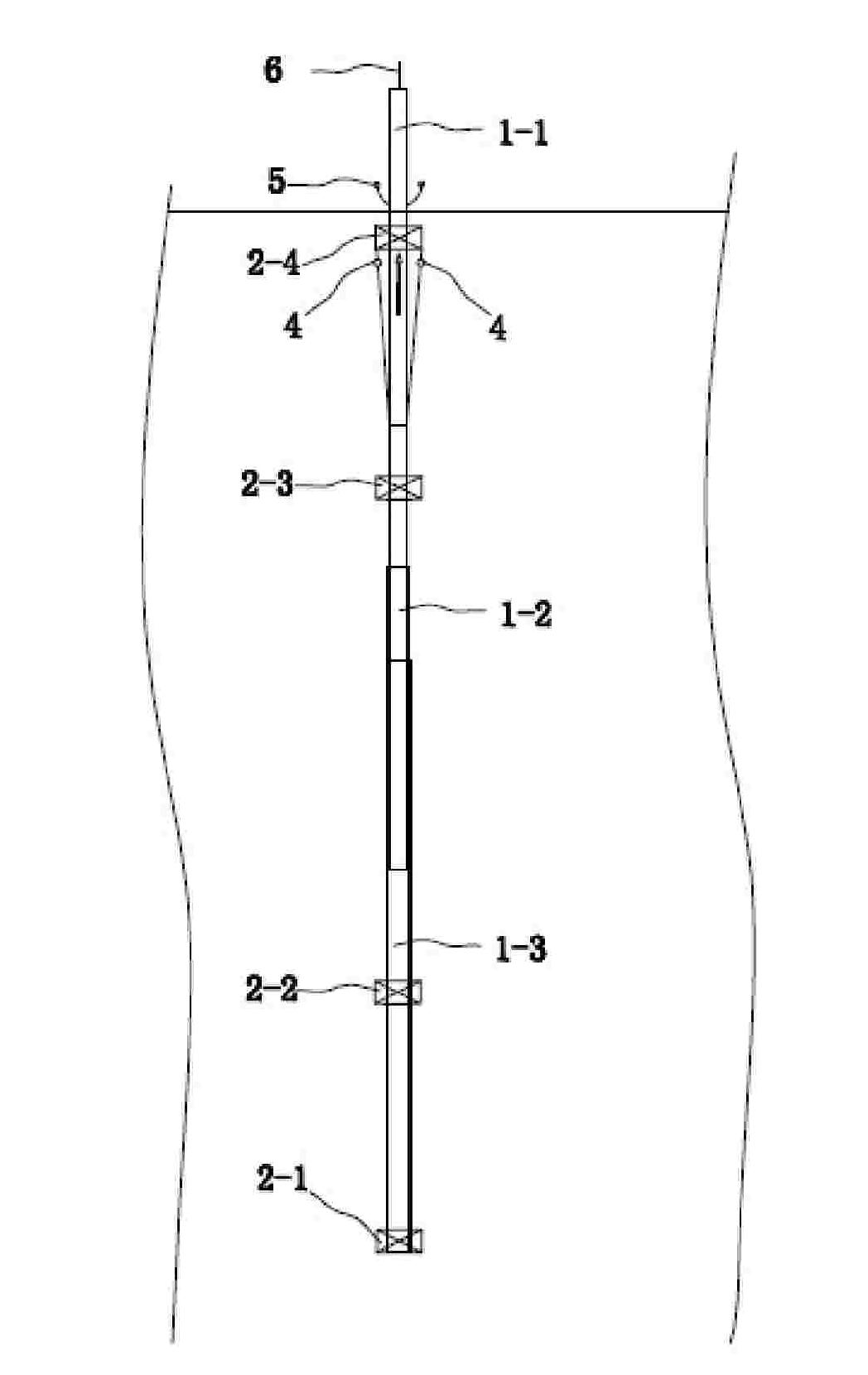

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer of steel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower end of the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Description

How to install a roof mast technical field The invention relates to a method for installing a roof mast, in particular to a method for accumulatively lifting and assembling a sleeved mast. Background technique The installation of towering structures, especially the masts on the top of buildings, has always been a difficult point in construction, mainly due to the heavy weight and height of the towering masts, and the poor environment of the construction site where there is no large-scale installation machinery. Due to the fact that the lifting performance of the construction machinery cannot meet the lifting height and lifting capacity and other factors, the hydraulic climbing (jacking) method, the pulling method, the scaffolding load-bearing bulk method, etc. are used for construction. Some of these methods have relatively poor construction techniques. Complicated (hydraulic climbing, etc.), some have high labor intensity and high technical requirements (screwing method),...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04H12/34E04G21/14

Inventor 庄彤

Owner CHANGZHOU NO 1 CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com