Vertical type ground hinge mechanism

A ground hinge and hinge technology, used in building structures, door/window fittings, buildings, etc., can solve the problems of low bearing capacity, easily damaged parts, complex structure, etc., and achieve large bearing capacity, accurate and stable positioning, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

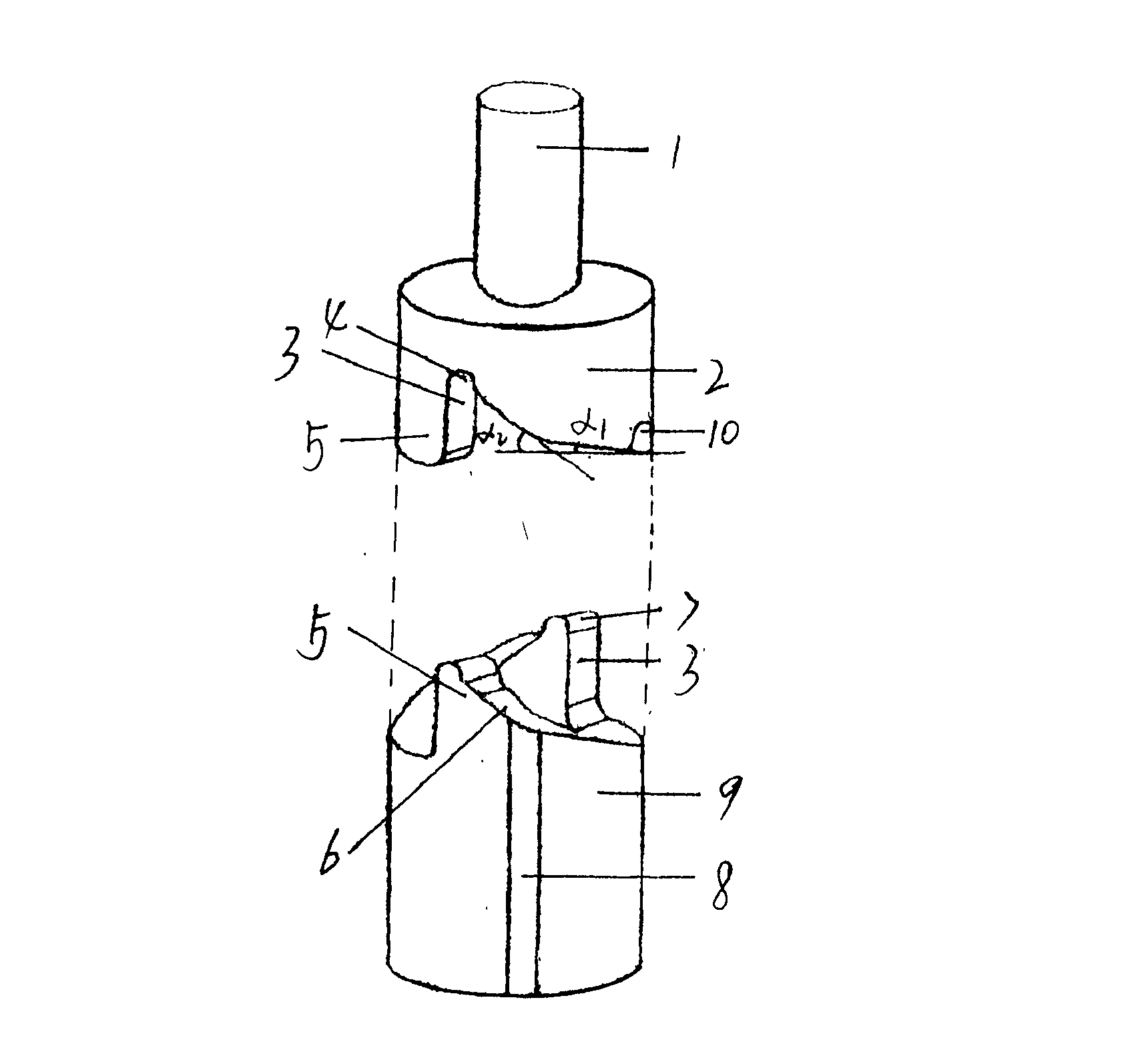

[0016] Such as figure 1 As shown, the vertical hinge mechanism of the present invention is composed of an upper hinge 2 and a lower hinge 9, and the meshing surfaces 6 of the upper hinge 2 and the lower hinge 9 are respectively provided with two symmetrical annular meshing teeth 5, and the meshing teeth 5 The engaging surface 6 is a helical surface (helix angle a=a 1 =a 2 =25°), the end face of one side of the meshing tooth 5 is an upright stop surface 3, so that the upper and lower hinges (doors and windows) can only be opened in one direction, and automatically reset within 180°; the end face of the upper hinge 2 is provided with a fixed shaft 1 , the body of the lower hinge 9 is provided with a keyway 8; the meshing teeth 5 are respectively provided with a raised semicircular U-shaped positioning tooth 7, and the corresponding upper hinge tooth root is set as a recessed semicircular U-shaped door closing stop positioning groove 4. There is a door opening angle positioning...

Embodiment 2

[0019] On the basis of Embodiment 1, the helix angle of the meshing surface 6 of the upper hinge 2 and the lower hinge 9 adopts a two-stage structure, that is, the helix angle is respectively: a 1 = 15°, a 2 = 32°. When the door is opened, the principle is the same as in Embodiment 1. When the door is closed, the lower hinge 9 is on a slope with a small helix angle of α1, and moves slowly to prevent hitting people. When entering a slope with a large helix angle α2, the rotation speed is accelerated until the door When about to close, the positioning tooth 7 on the lower hinge 9 quickly enters the door closing stop positioning groove 4 li on the upper hinge 2, and the door is stably positioned in the closed state, so that the access control system enters the locked state accurately.

Embodiment 3

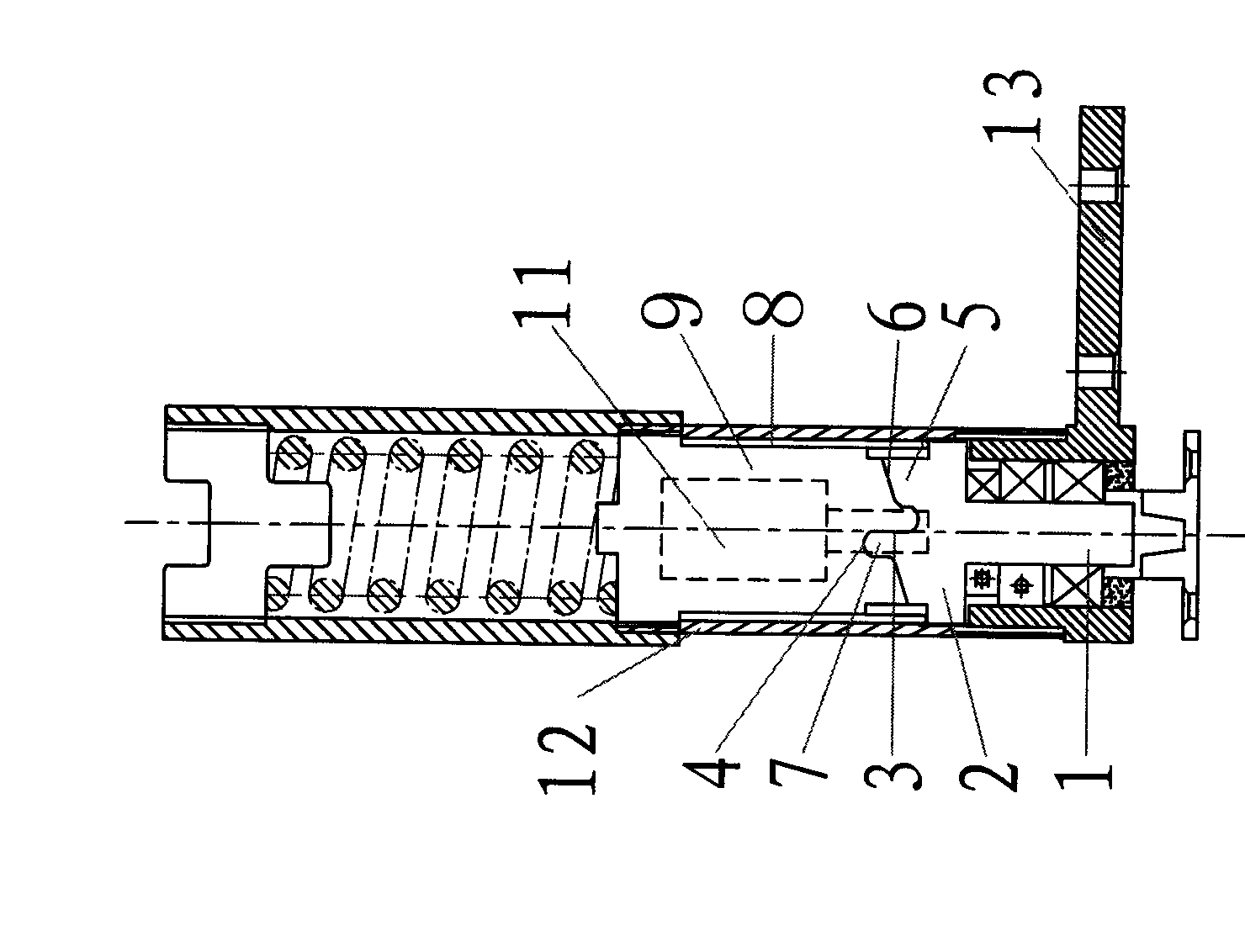

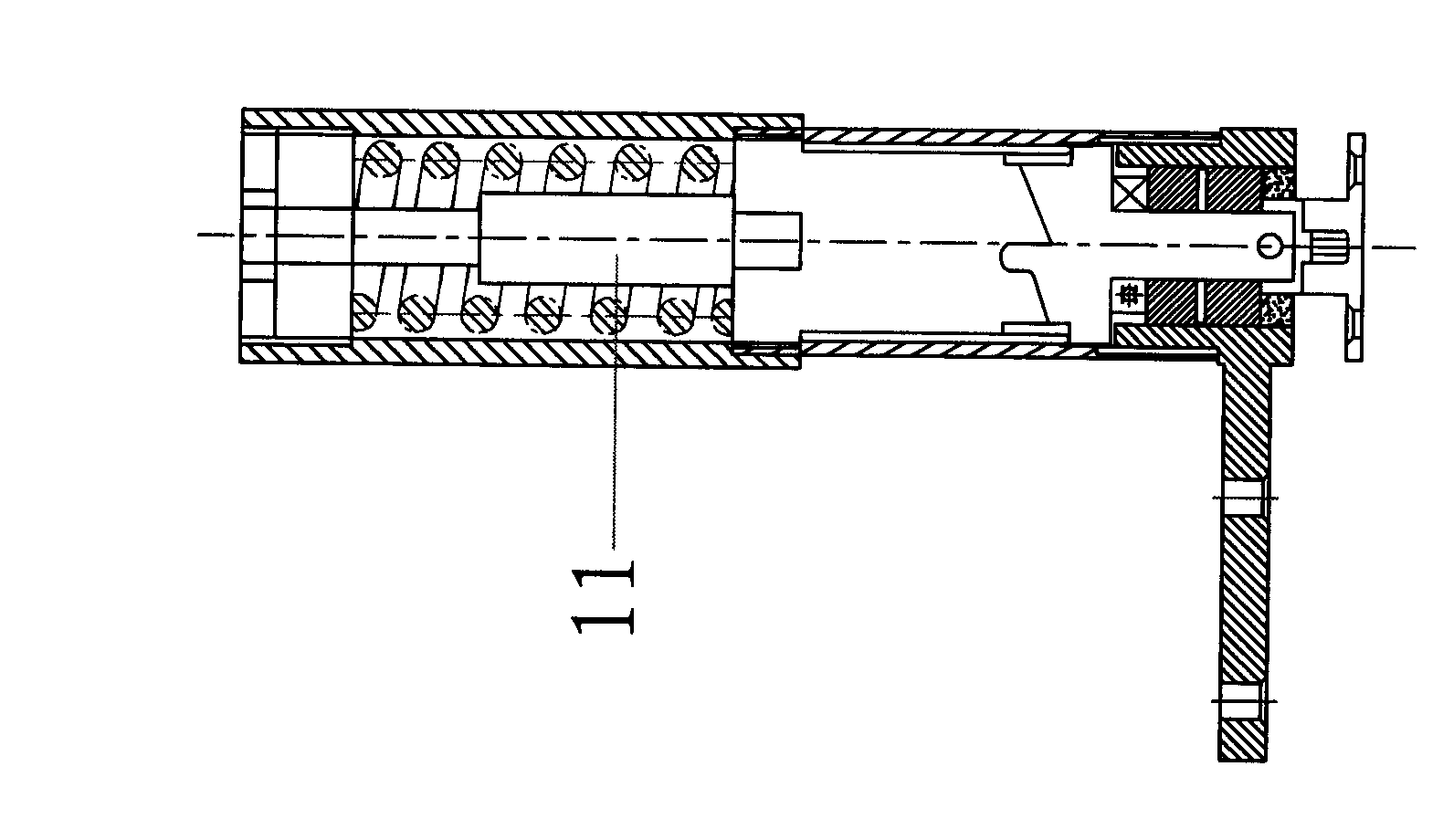

[0021] On the basis of Embodiments 1 and 2, the damper part 11 is fastened at the inner cavity between the upper hinge 2 and the lower hinge 9 (see figure 2 This example is a miniature damper assembly), or a damper part 11 is fastened at the end of the lower hinge 9 (see image 3 This example is the damper assembly) when the door is opened, the principle is the same as in embodiments 1 and 2. When the door is closed, the lower hinge 9 is slowly combined under the action of the damper when the door is closed, so as to avoid the impact sound when the two meshing gears are fully meshed, and achieve a quiet effect. Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com