Liquid-cooled light distribution hollow type LED lamp

A technology for LED lamps and LED light sources, applied in the field of LED lamps, can solve the problems of increasing product weight and installation difficulty, harsh sealing of heat dissipation boxes, and difficulty in selecting coolant, and achieves the advantages of improving effective luminous flux, light weight and improving heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] specific implementation plan

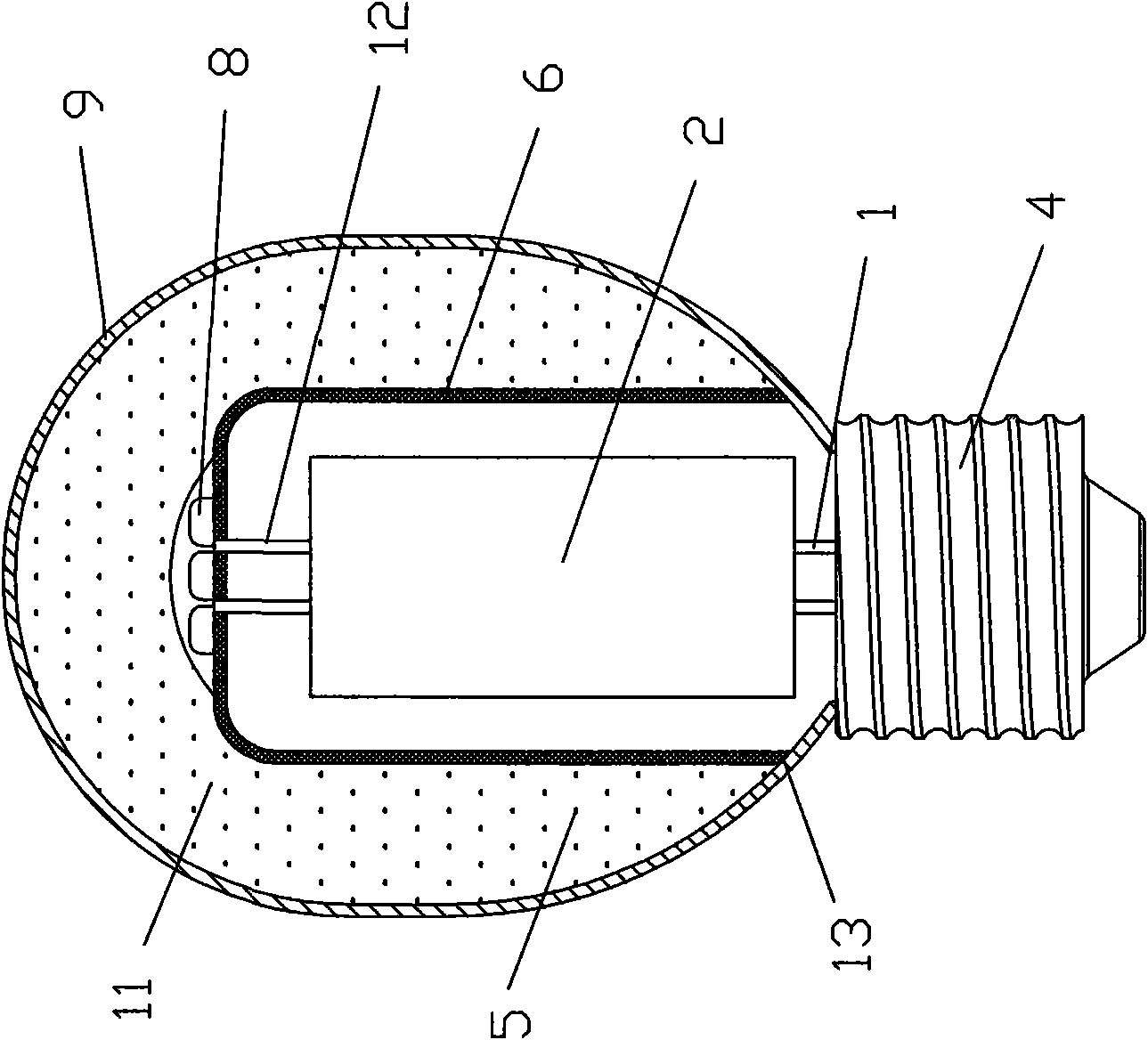

[0043] The first embodiment of the present invention is as image 3 shown. The embodiment of the present invention provides a liquid-cooled light distribution hollow LED lamp, including an electrical connector 1 , an LED driver 2 , a lamp holder 4 , a hollow radiator 6 , an LED light source 8 , a light distribution lampshade 9 , and an LED connection wire 12 . The electrical connector 1 is arranged inside the lamp cap of the LED lamp to connect to the mains, and it is connected to the input of the LED driver 2. The cavity 11 between the hollow radiator 6 and the light distribution lampshade is filled with high-performance heat-conducting The light distribution liquid 5 , the LED driver 2 is arranged in the built-in hollow chamber 10 formed by the hollow radiator 6 , and the LED light source 8 is arranged on the hollow radiator 6 . The connection line 12 of the LED light source 8 is connected to the LED driver 2 in the hollow chamber 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com