Device for measuring throat area error of nozzle guide vane

A turbine guide vane and error measurement technology, which is applied in the direction of electromagnetic measuring devices, electric/magnetic area measurement, etc., can solve the problems that the measurement accuracy and measurement speed cannot meet the production needs, consume a lot of money and time, and have low measurement efficiency. The effect of convenient measurement, satisfying production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

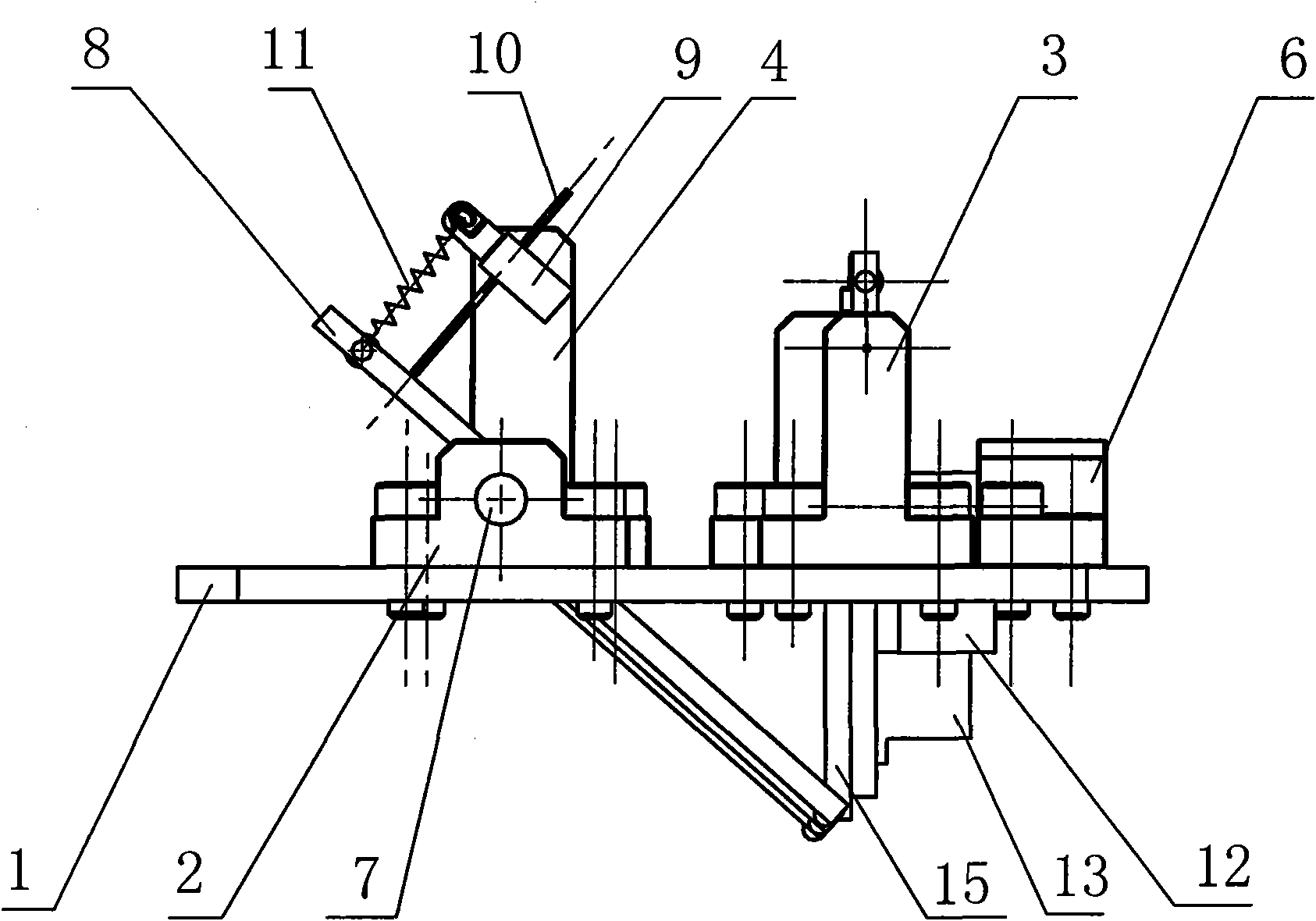

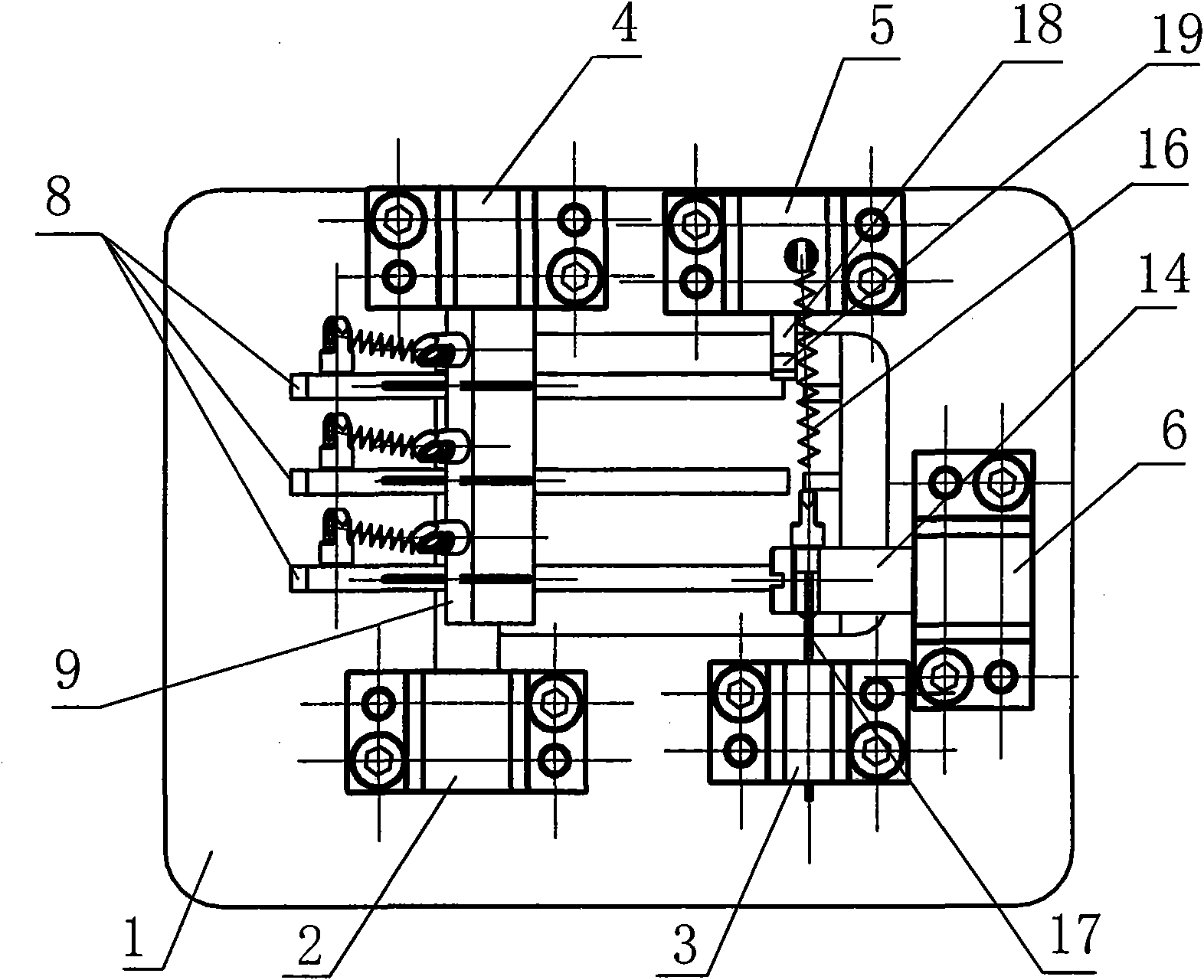

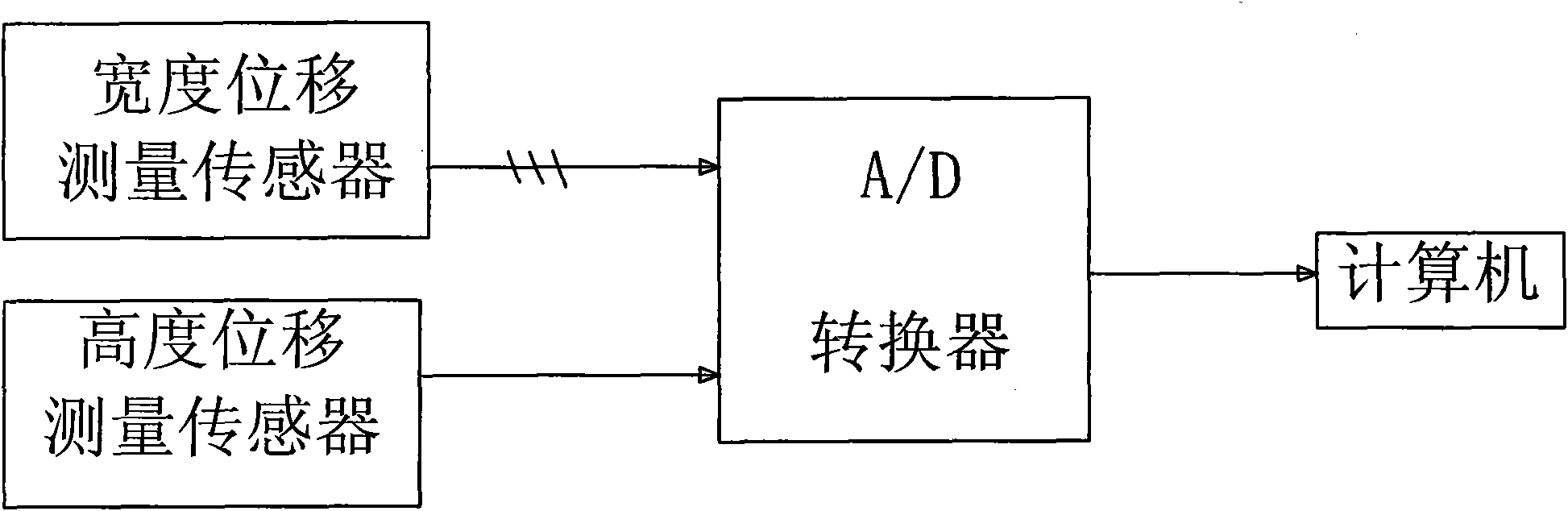

[0022] refer to figure 1 , figure 2 , image 3 , is an error measuring device for the throat area of the turbine guide vane. It includes a substrate 1 with a rectangular hole in the center, a front left support seat 2 and a front right support seat 3 which are respectively fixed by screws on the front edge of the rectangular hole on the upper surface of the substrate 1, and a rear seat which is respectively fixed by screws on the rear edge of the rectangular hole. The left support seat 4 is positioned at the right support seat 6 fixed by screws on the right edge of the rectangular hole.

[0023] A first fixed shaft 7 extending toward the rear of the base plate 1 is provided on the front left support base 2 , and three width measuring rotating rods 8 are sequentially arranged along the axial direction of the first fixed shaft 7 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com