Method for measuring cylinder in pile directly

A measurement method and column technology, which is applied to the determination of fixed angles and other directions, and can solve problems such as inability to accurately measure verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

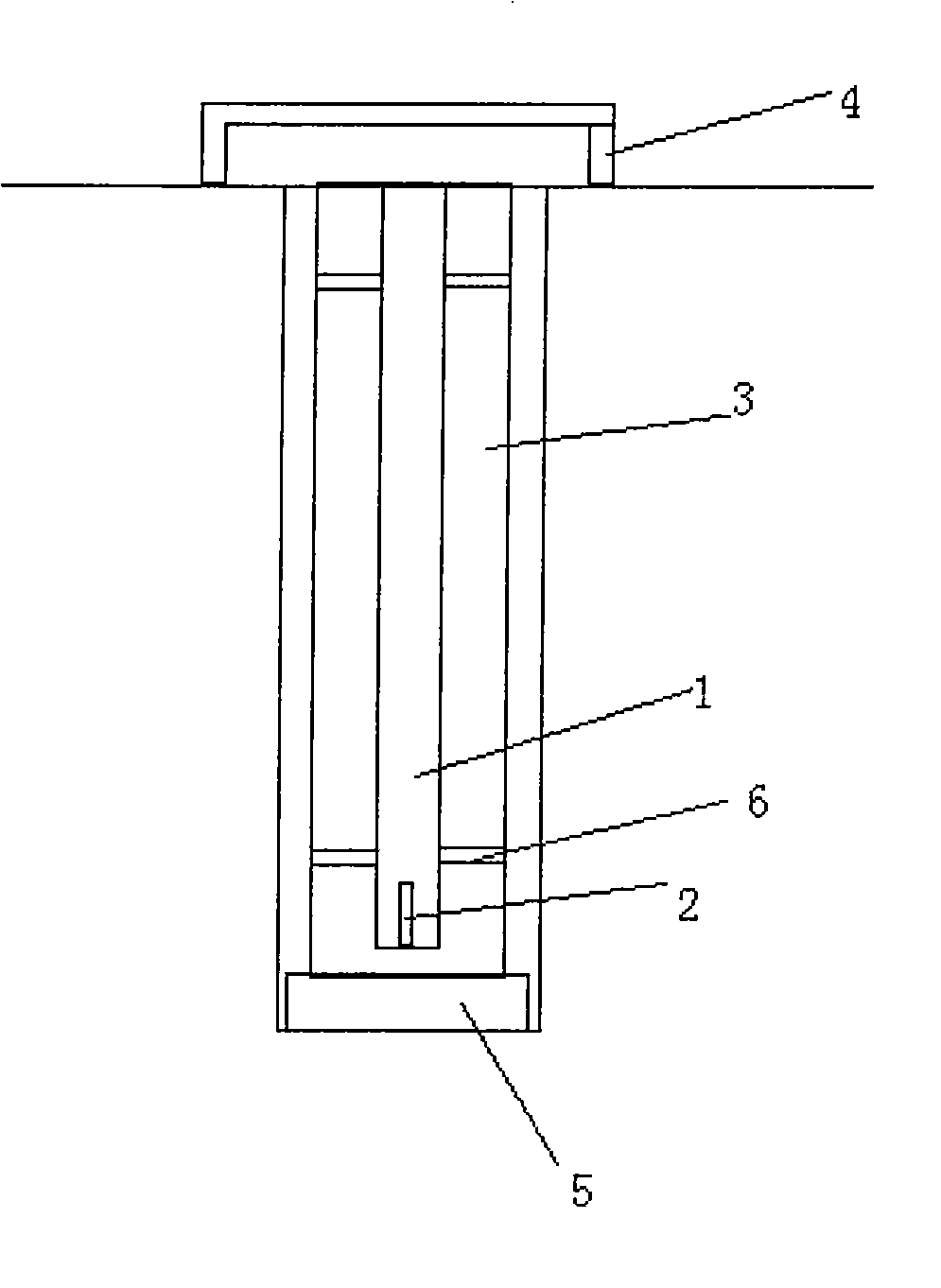

[0006] First, a round tube 1 with a closed bottom is placed inside the cylinder 3, and a measurement reference point is built in the center of the bottom of the round tube 1. A laser pointer 2 can be selected, and the laser pointer 2 is placed upward so that the laser beam follows the center line of the round tube 1. Injection, place the centerline of the round pipe 1 on the centerline of the rigid steel column 3 on the ground, and fix it with the rigid steel column 3 with a fixed bracket 6, so that it can be pulled out after the construction is completed, and the next column will be corrected use. Set the fixed frame 4 on the ground in advance, and mark the theoretical axis position of the corresponding pile foundation and mark the reference point of the theoretical axis position of the pile foundation on the fixed frame 4, put the rigid steel column 3 into the pile body 5 and place it The center of its top is adjusted on the theoretical axis position of the corresponding pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com