Protection starter

A technology for protecting starters and protectors, which is applied to substations/switchgear boards/panels/desks, electrical components, substations/distribution device shells, etc. It can solve contactor burnout, large protection errors without motor protection devices, and wiring Issues such as unclear identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

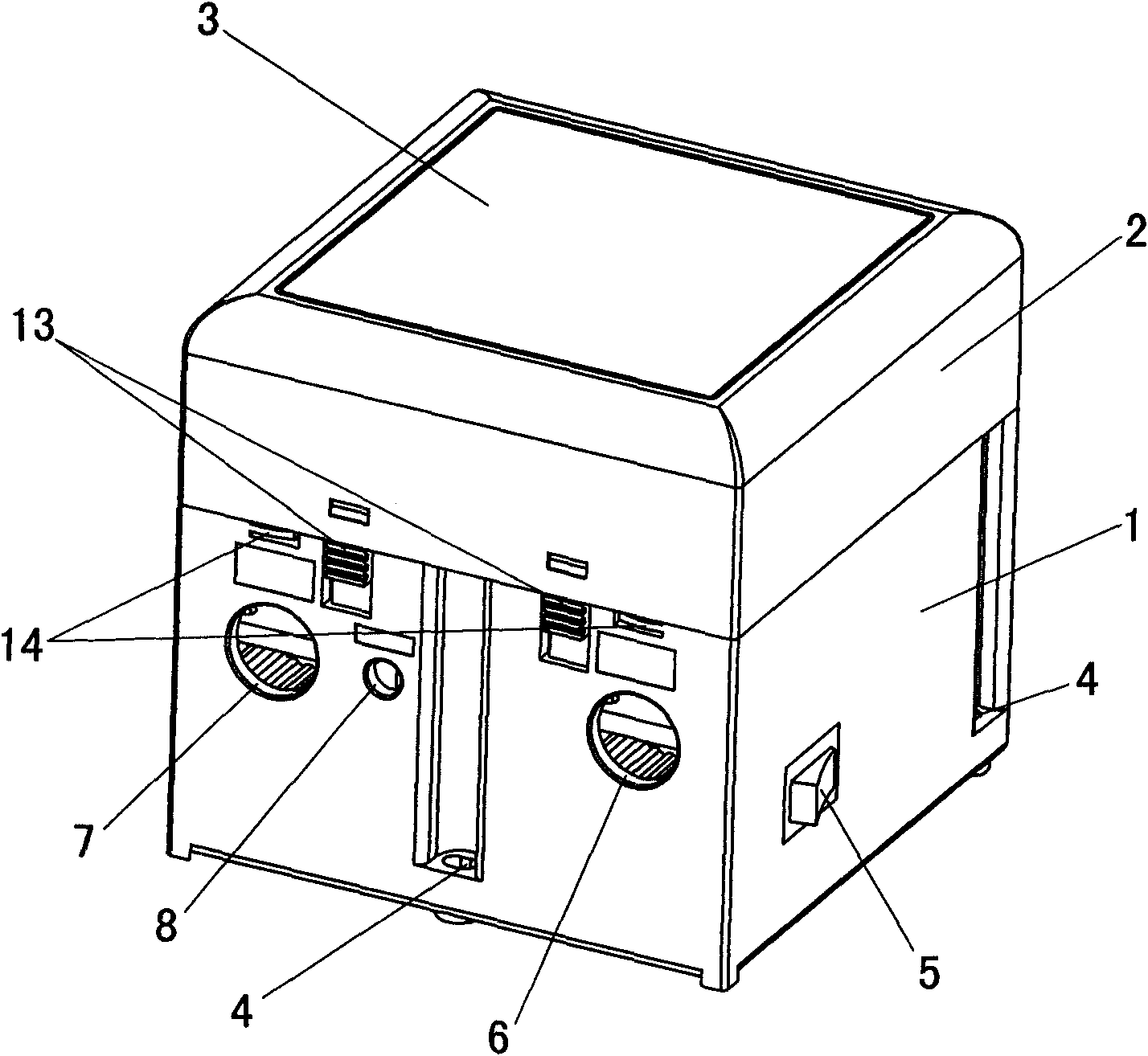

[0014] figure 1 It is a schematic diagram of the outer structure of the protective starter shell. The main shell (1) and the transparent cover (2) are both molded and injection molded. The plastic material of the main shell (1) is thick and firm and opaque, and the transparent cover (2) is transparent. Plastic material, you can observe the internal structure and status indicators, etc.

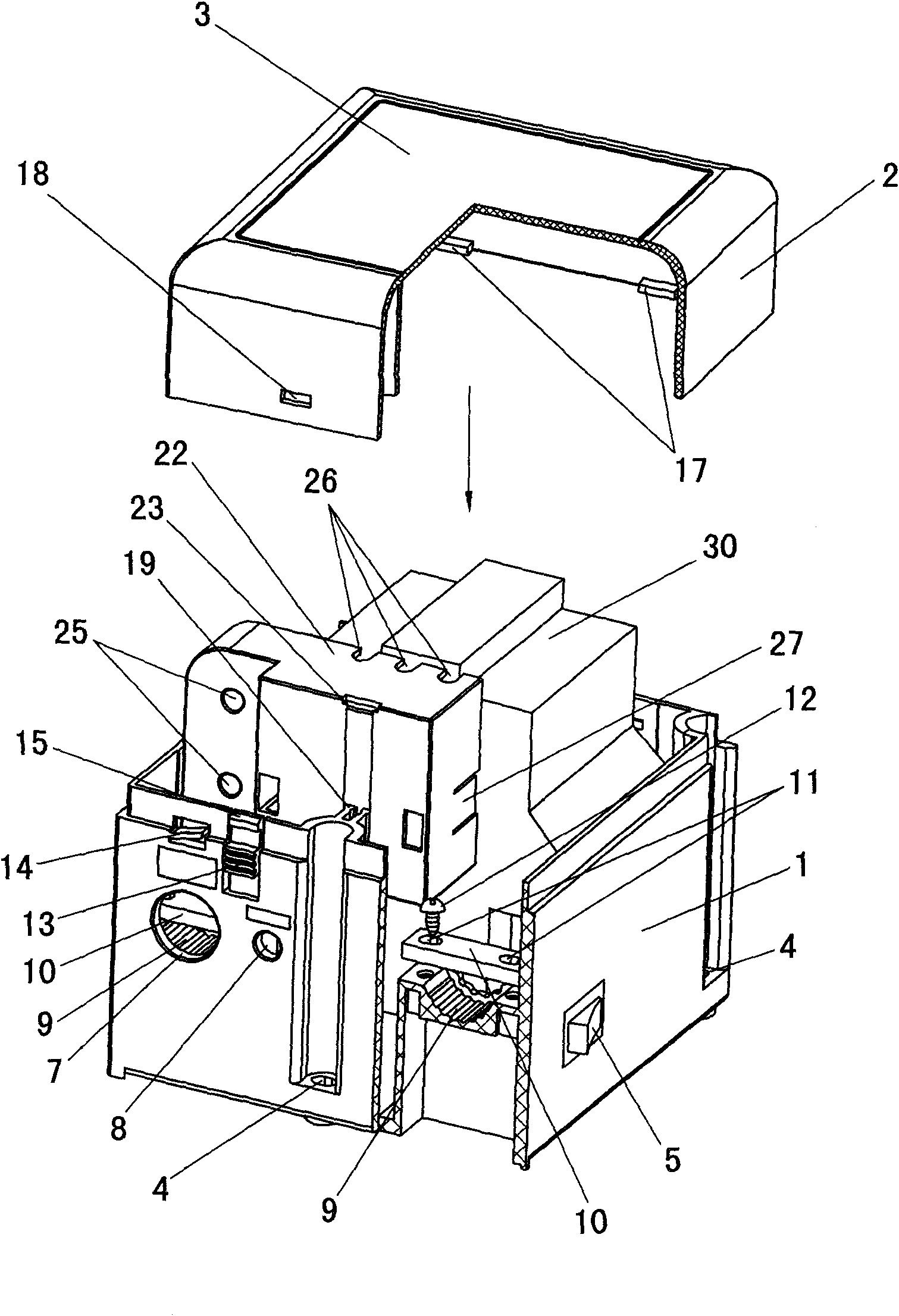

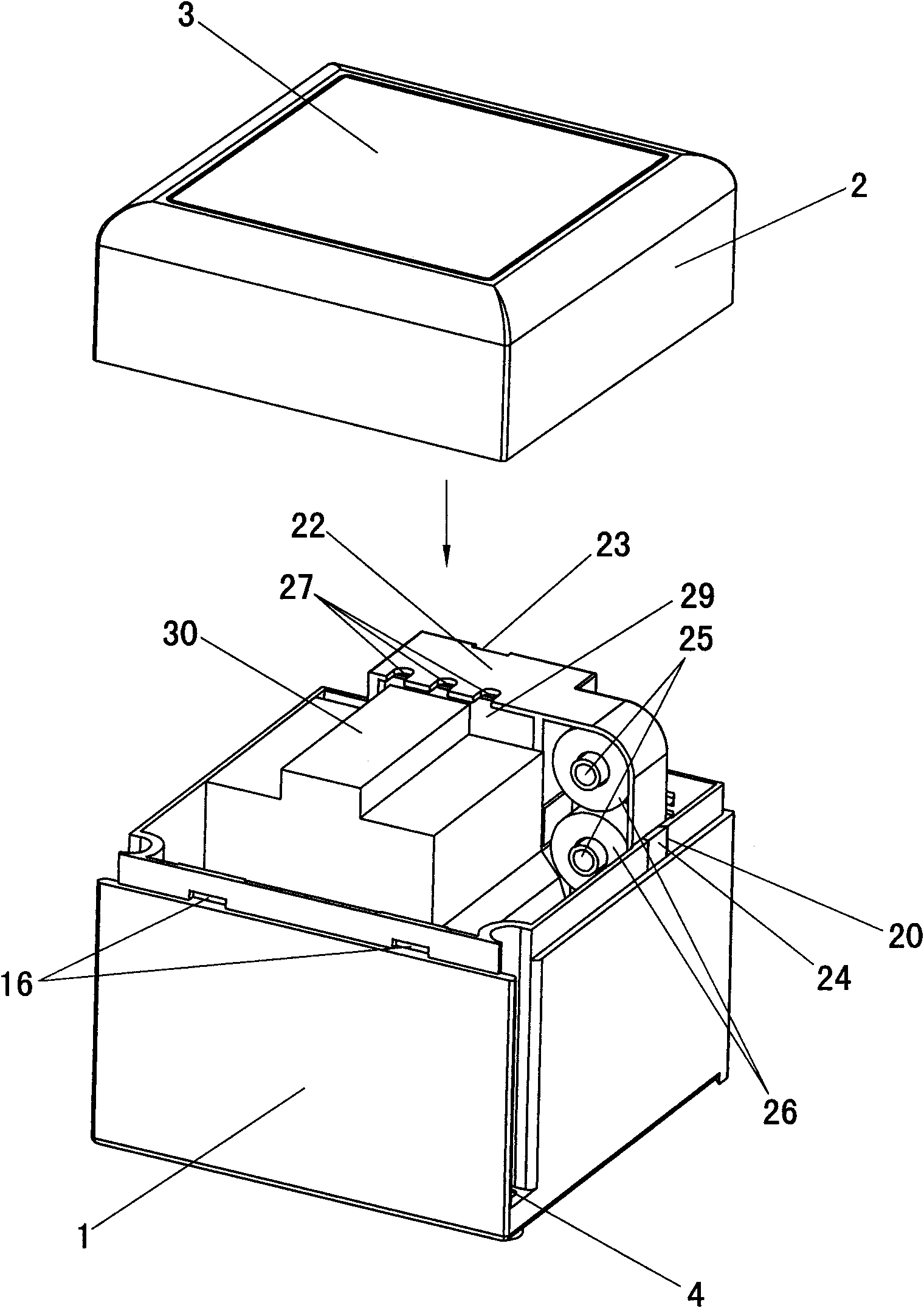

[0015] figure 2 , image 3 , Figure 4 It is a schematic diagram of the structure of the protective starter housing. The three fixed mounting holes (4) of the main housing (1) are designed to be distributed on both sides and the lower part outside the main housing (1), which is convenient for fixing; the protector module (22) passes through The dovetail installation groove (23) and the dovetail card (24) are connected and fixed on the main housing (1) with the Y-shaped chuck (19) and the dovetail groove (20); the AC contactor (30) is connected with the AC contactor fixing hole ( 21) Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com